Conduction oil electromagnetic wave heating system for rubber powder modified asphalt production line

A technology of heat transfer oil heater and modified asphalt, which is used in heat storage heaters, fluid heaters, melting and processing tar pitch/petroleum pitch/natural pitch, etc., can solve the problem of increased energy consumption, low thermal efficiency and increased production cost and other problems to achieve the effect of reducing configuration, reducing production costs, and avoiding secondary transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

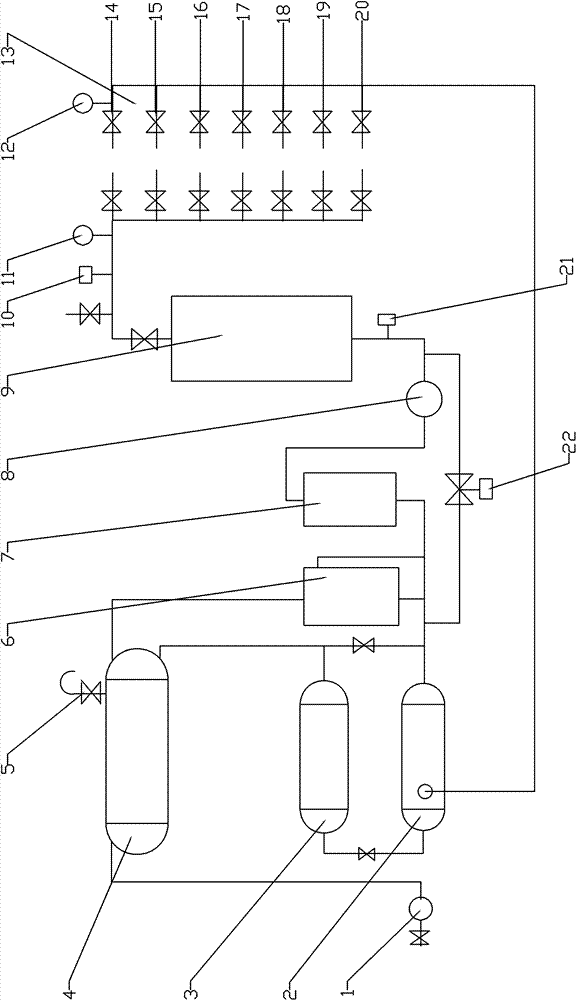

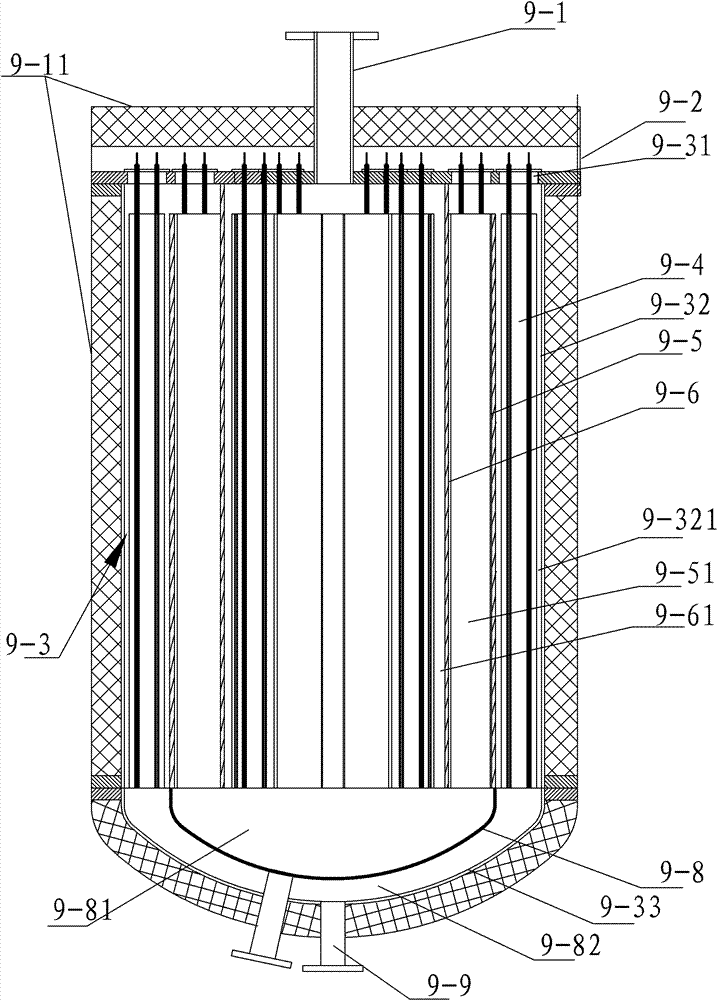

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a heat conduction oil electromagnetic wave heating system of a rubber powder modified asphalt production line mainly consists of heat conduction oil distributor 13, electromagnetic wave heat conduction oil heater 9, heat conduction oil pre-expansion tank 4, heat conduction oil expansion precooling tank 3, heat conduction The oil expansion tank 2, the heat transfer oil oil-gas separator 6, the heat transfer oil filter 7, the heat transfer oil circulation pump 8 and the heat transfer oil injection pump 1 constitute a closed heat transfer oil circulation heating system, the heat transfer oil oil-gas separator, the heat transfer oil filter , the heat transfer oil circulation pump is connected with the electromagnetic wave heat transfer oil heater and the heat transfer oil distributor in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com