Self-rotating and cleaning device of dirt in heat transfer tube

A technology for cleaning devices and heat transfer tubes, which is applied in the directions of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc. The effect of reduction, less fluid resistance, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Implementation example:

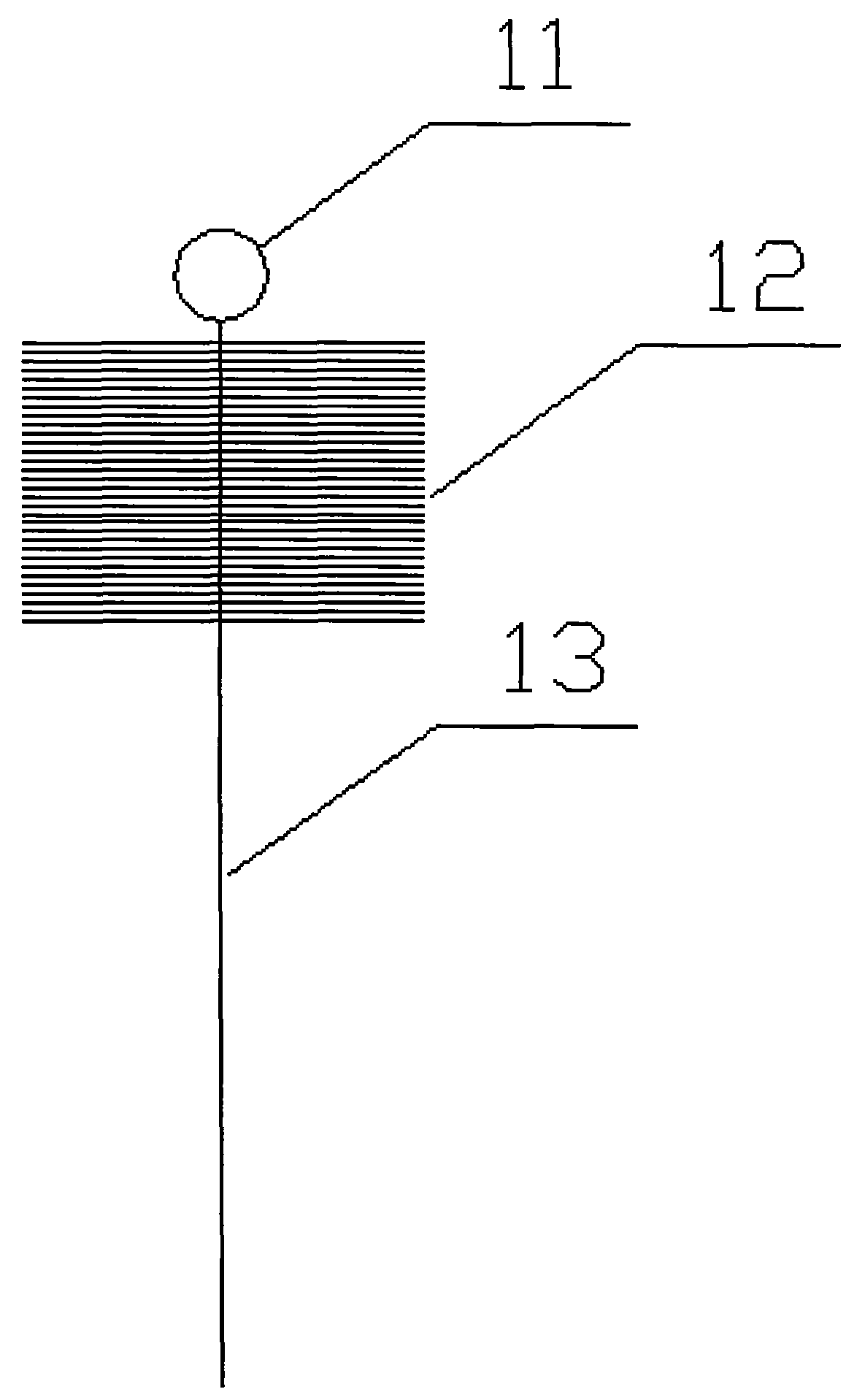

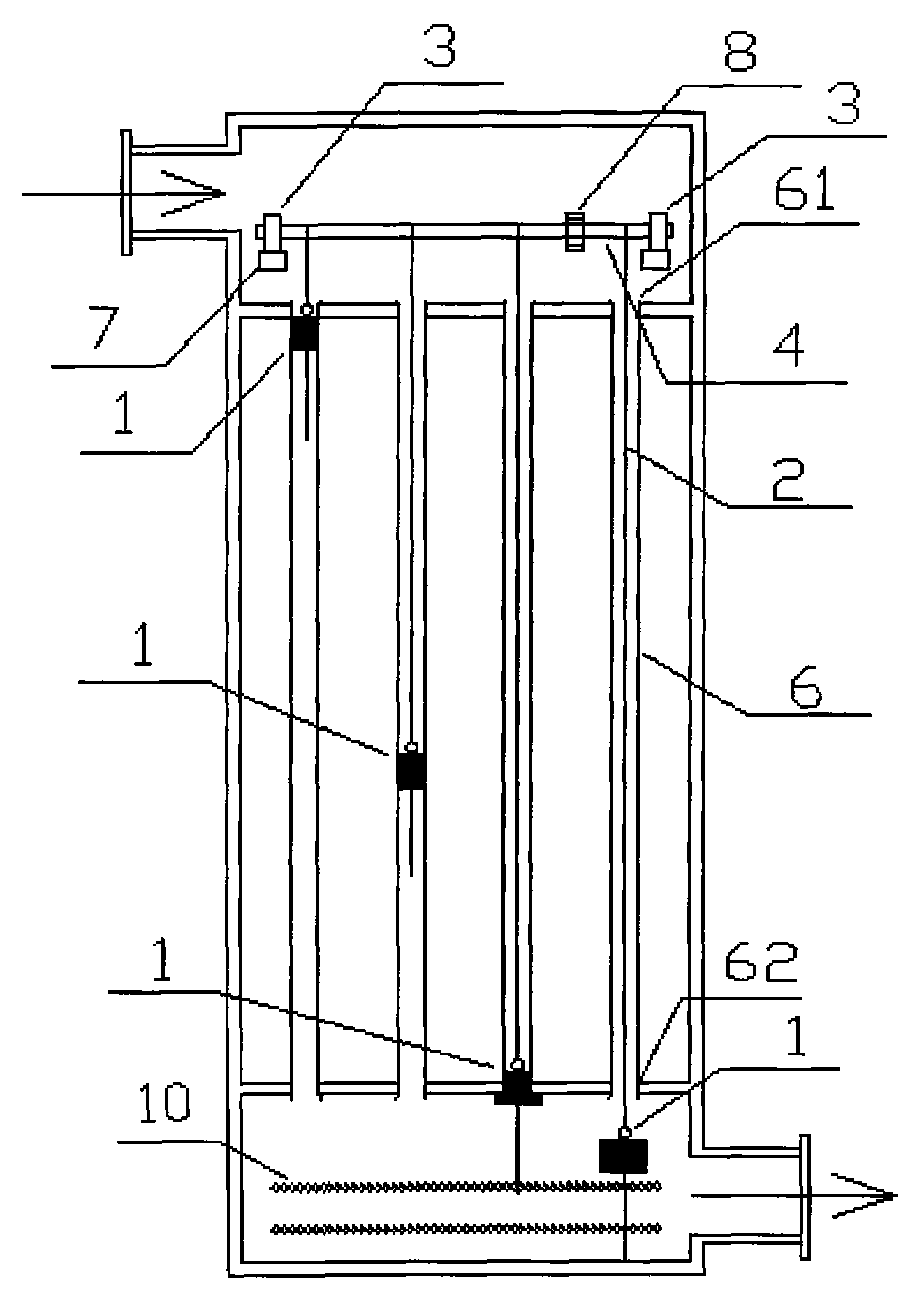

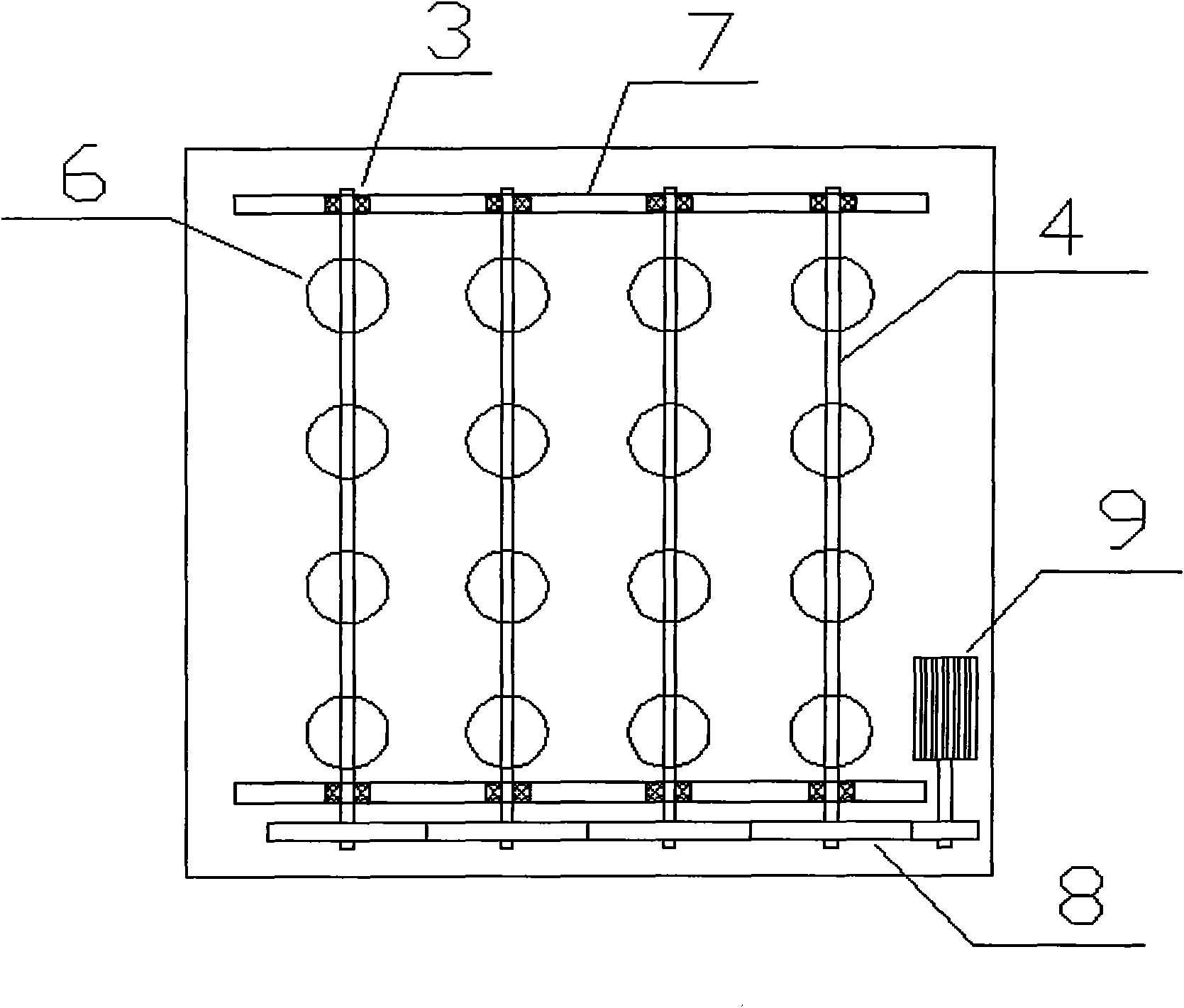

[0019] The structure diagram of the present invention is as figure 1 , 2 , shown in 3, including heat exchanger heat transfer tube 6, spiral brush 1, heat exchanger heat transfer tube 6 is provided with pipe inlet 61 and pipe outlet 62, and spiral hair brush 1 is placed in heat exchanger heat transfer tube 6, and can move linearly in the heat transfer tube 6 of the heat exchanger, and the spiral brush 1 can pass through the outlet 62 of the heat transfer tube 6 of the heat exchanger, and the spiral brush 1 is installed on the On the traction shaft 4, one end of the connecting rope 2 is connected to the spiral brush 1, and the other end of the connecting rope 2 passes through the inlet 61 of the heat transfer tube 6 of the heat exchanger and is fixed on the traction shaft 4, and the traction shaft 4 passes through the transmission mechanism 8 is connected with drive unit 9.

[0020] In this embodiment, the outer side of the pipe outlet 62 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com