Device and method for measuring object to be measured having hollow circular cylindrical shape, and device for inspecting external appearance of tire

A measuring device and a technology to be measured, applied in the field of devices, can solve the problems of long operation time, tire deformation, and inability to easily obtain tire size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

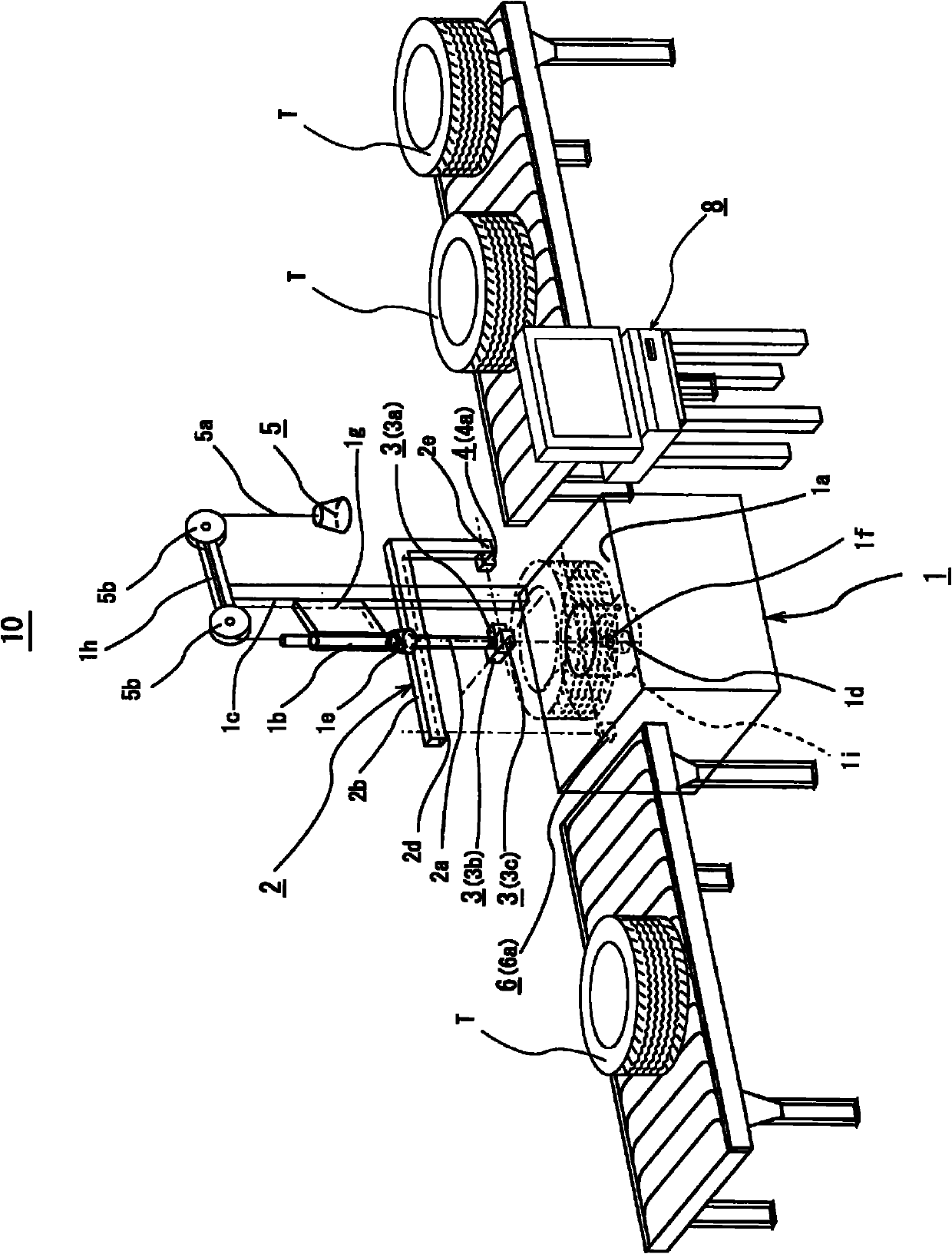

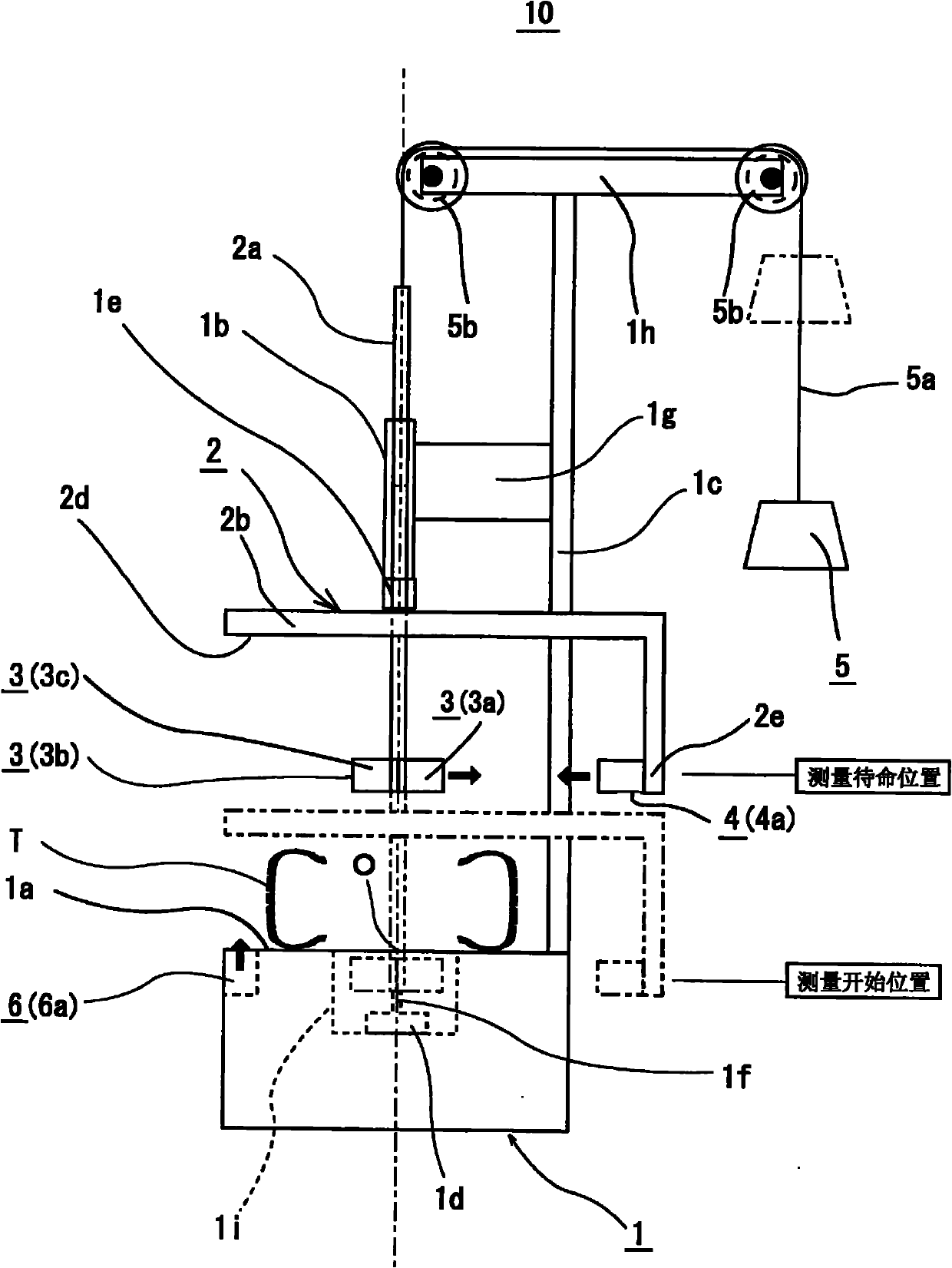

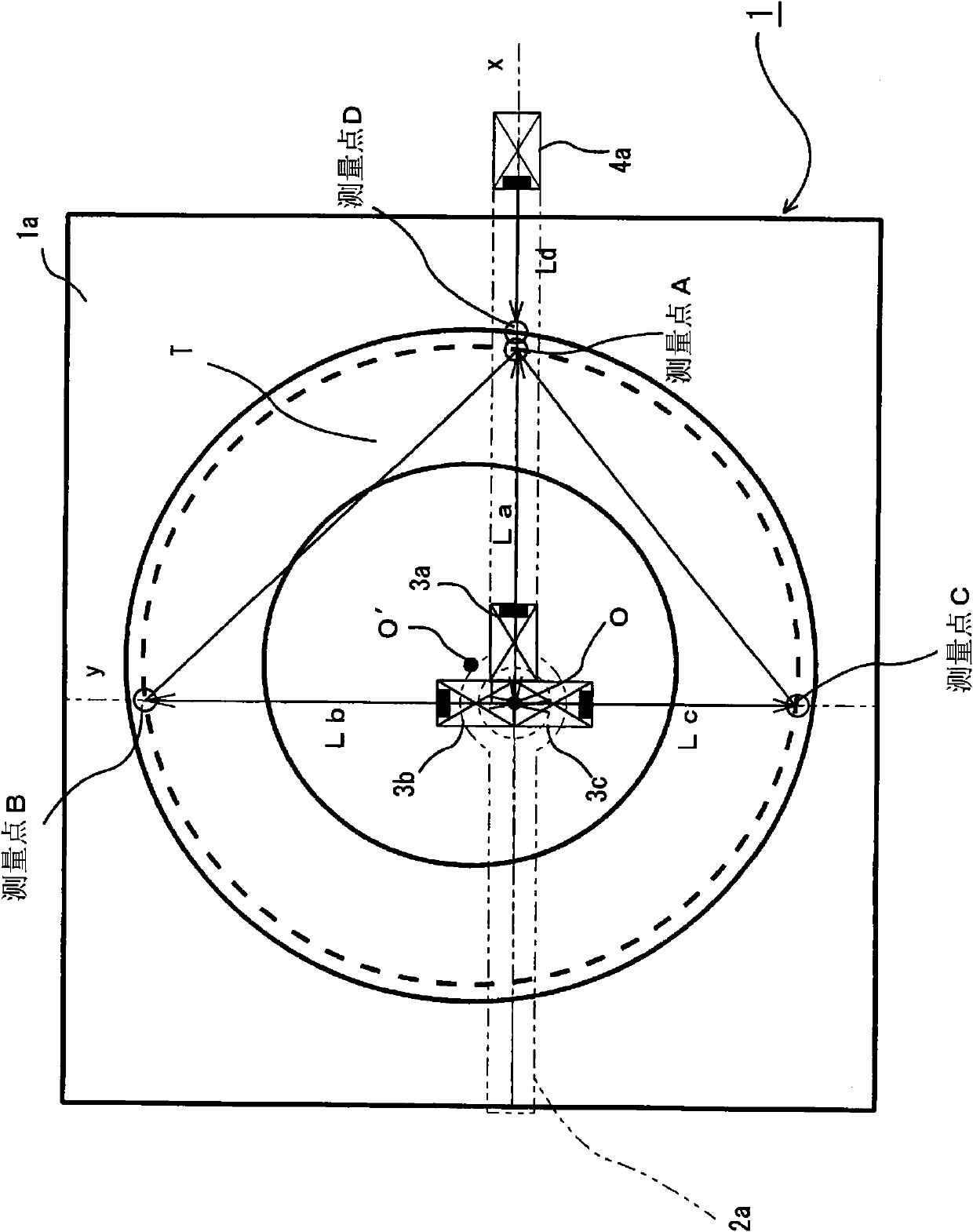

[0026] figure 1 is an external view showing the size and shape measuring device of the present invention, figure 2 It is a block diagram showing the size and shape measuring device. The measurement device 10 includes a measurement table 1 , a measurement head 2 and an arithmetic processing device 8 .

[0027] The measuring stand 1 includes a mounting surface 1a on which a cylindrical object T such as a tire is mounted, a height displacement measuring device 6, a lower stopper 1d, and a support 1c. The mounting surface 1a is located on the upper surface of the measuring table 1, and has a recessed portion 1i at the center thereof. A lower stopper 1d is provided in the retreat portion 1i. The pillar 1c extends in the vertical direction on the side of the measuring table 1, and includes a guide support 1g and a pulley support 1h. One end of the guide support 1g is fixed to the pillar 1c and a positioning guide 1b is fixed at the other end. The positioning guide 1b is formed i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap