Measuring system and method for concrete stress distribution in steel pipe of arch bridge based on stepped section

A technology of stress distribution and measurement system, which is applied in the measurement of force, measurement device, and force measurement by measuring the change of optical properties of materials when they are stressed. Creep and other problems, to achieve the effect of improving measurement accuracy, increasing sensitivity, stress and stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

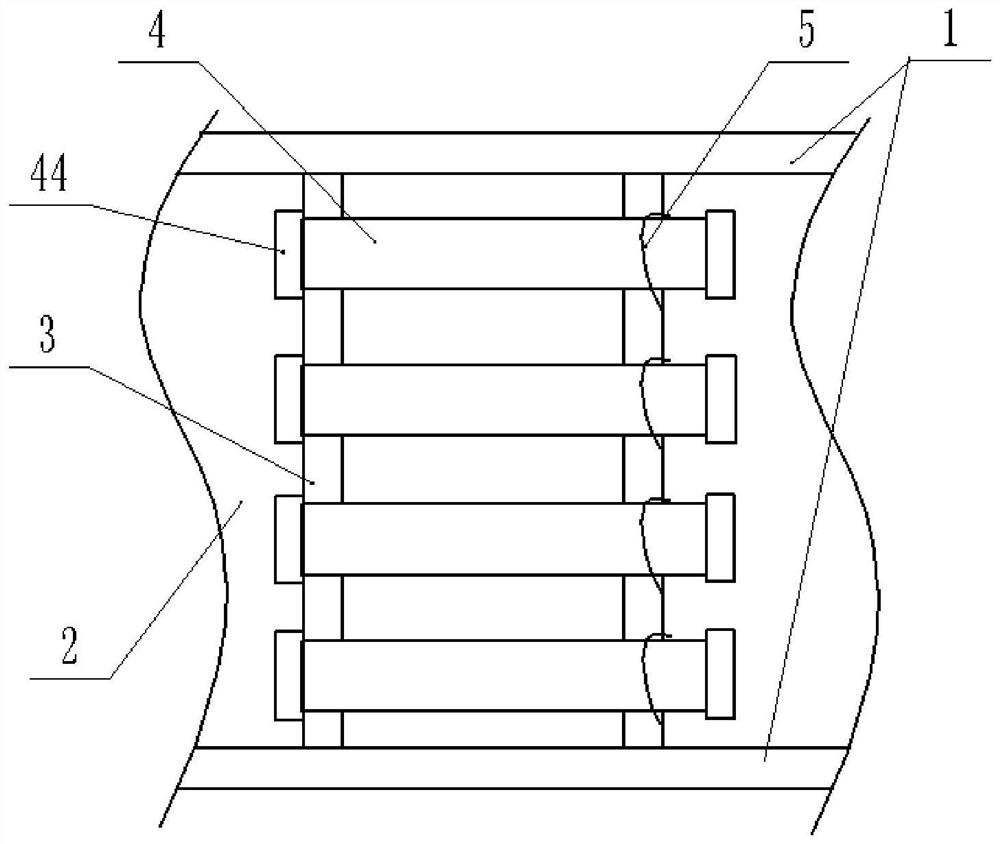

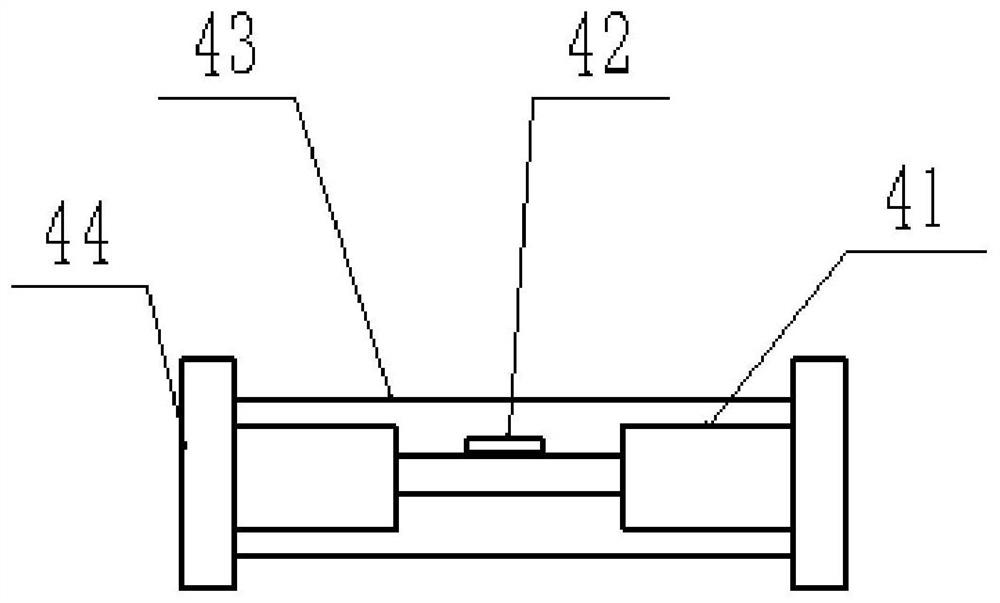

[0040] Such as figure 1 with image 3, a system for measuring the stress distribution of concrete in a steel pipe of an arch bridge based on a stepped section, comprising a steel pipe 1 and concrete 2 poured into the steel pipe 1, wherein a plurality of steel bars 3 are fixed in the steel pipe 1 along the radial direction of the steel pipe 1, Adjacent steel bars 3 are provided with sensors 4 . The sensor 4 includes a stepped rod 41 , a sensitive element 42 fixed on the middle of the stepped rod 41 and a protective cover 43 arranged outside the stepped rod 41 . The sensitive element 42 may be a fiber Bragg grating or a resistance strain gauge, etc., and is preferably a fiber Bragg grating in this embodiment. Both ends of the ladder bar 41 are also fixedly provided with end plates 44, and the convex parts of the end plates 44 away from the ladder bar 41 are all connected with the concrete 2 (that is, the end plates 44 are embedded in the concrete 2, so that the force in the c...

Embodiment 2

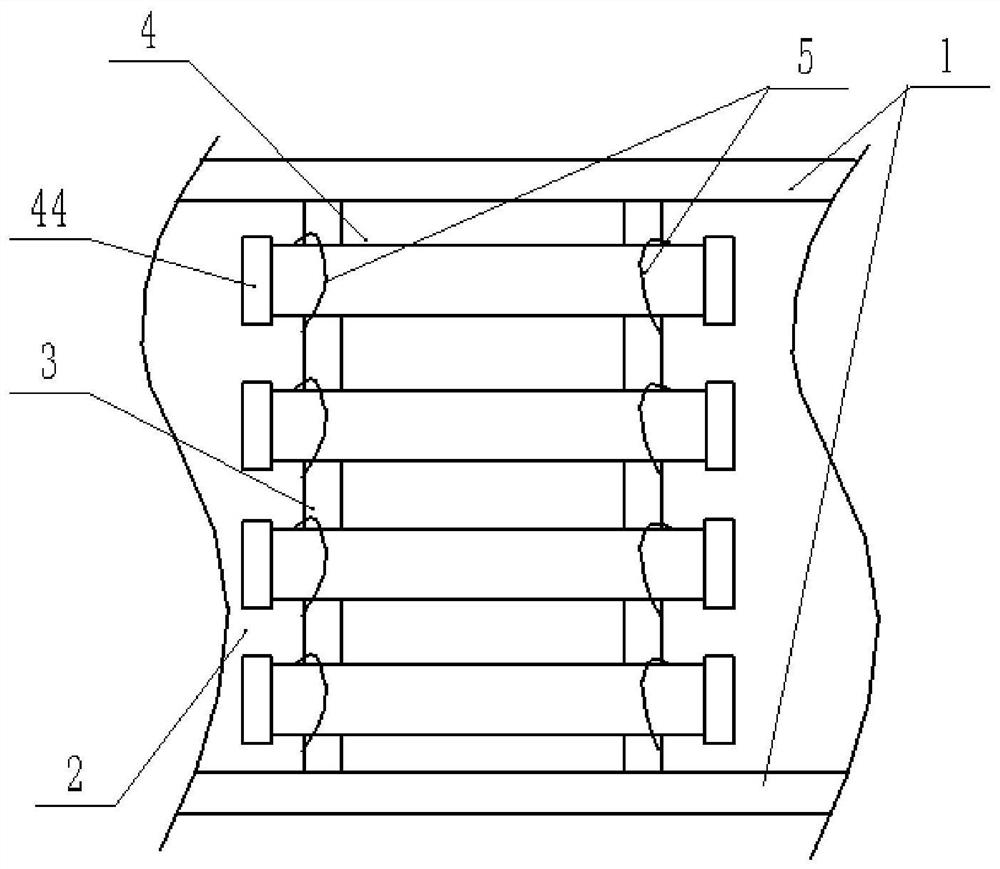

[0052] In addition to the above-mentioned stepped rod 41, the sensor 4 may also include a constant-section rod 45 (that is, the sensor 4 is a combined sensor), and the two ends of the constant-section rod 45 are fixed on the end plate. 44 and spaced apart from the ladder bar 41 . In the concrete stress distribution measurement system in the steel pipe of the arch bridge based on the stepped section in this embodiment, the sensor 4 includes one equal-section rod 45, two ladder rods 41, and the equal-section rods 45 are arranged on two Between the said ladder bar 41 (as Figure 4 ). Of course, in other embodiments, the number of stepped rods 41 and equal-section rods 45 can also be appropriately increased by the length of the end plate 45 . That is, other structural forms with different cross-sectional areas may also be used in other embodiments. In addition, both ends of the sensor 4 are positioned by the sensor positioning member 5, so that the two ends of the sensor 4 are ...

Embodiment 3

[0060] In the concrete stress distribution measurement system in the steel pipe of the arch bridge based on the stepped section in this embodiment, there are two equal-section rods 45 arranged in the sensor 4, one stepped rod 41, and the stepped rod 41 is arranged on two equal-section rods 45 between (such as Figure 5 ). Others are the same as the measurement system of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com