Lean hematite stage grinding and high intensity magnetism, gravity separation, negative ion reverse flotation technique

A stage grinding and hematite technology, applied in the direction of flotation, magnetic separation, solid separation, etc., can solve the problems of increasing the cost of mineral processing and increasing the load of mineral processing equipment, and achieve the effect of reducing the cost of mineral processing and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the embodiments in the accompanying drawings.

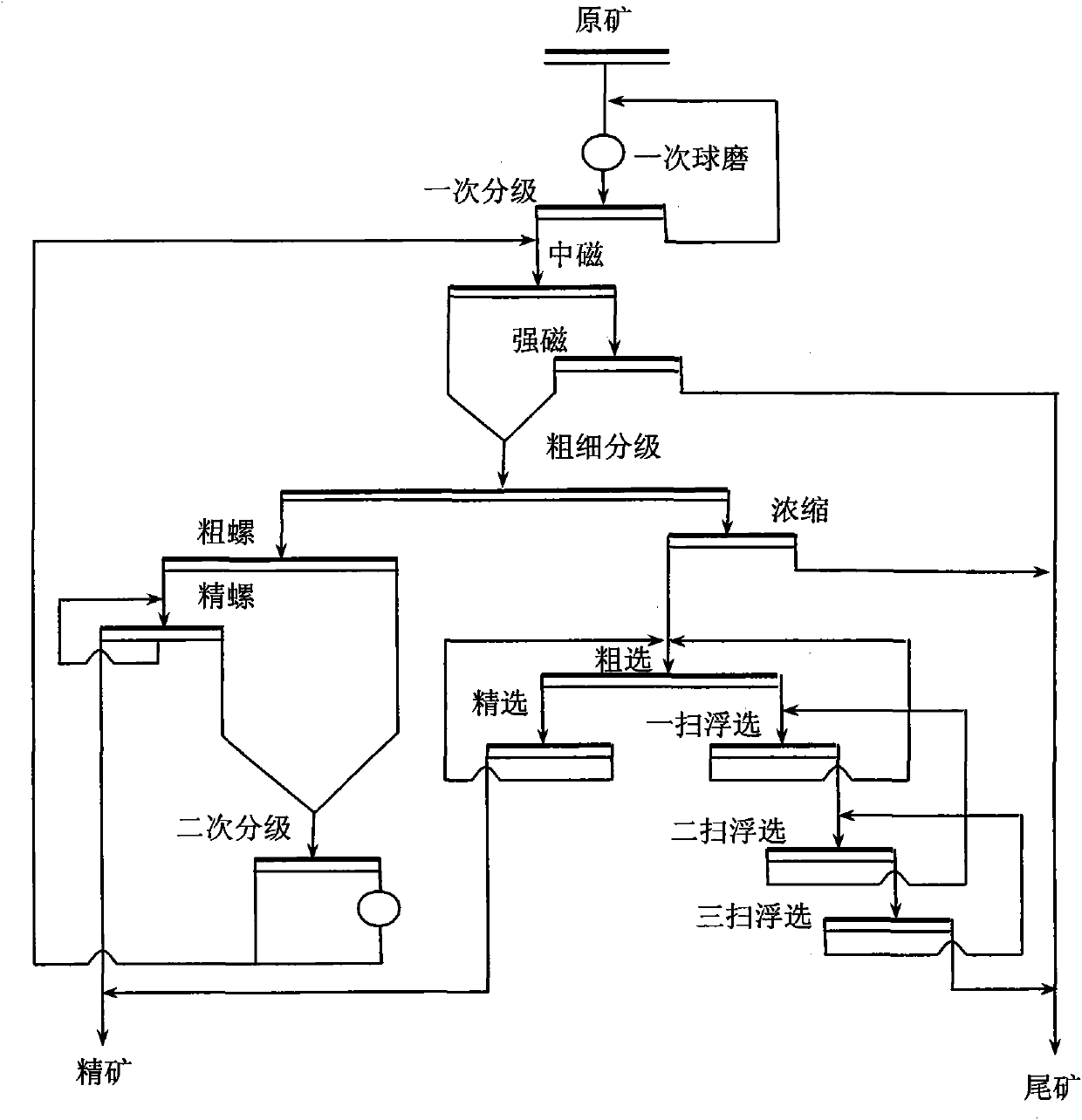

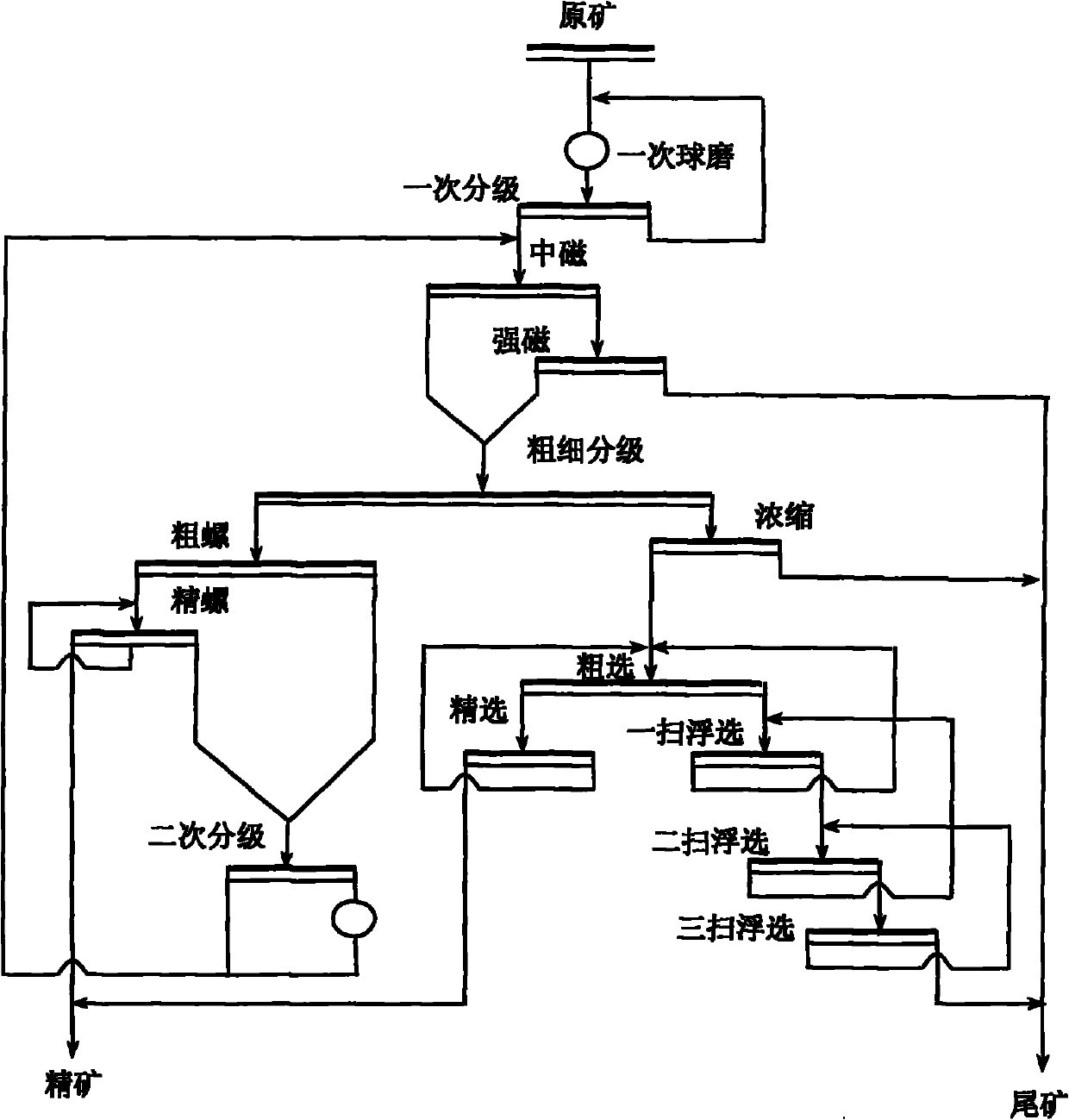

[0025] Such as figure 1 Shown, a kind of depleted hematite stage grinding of the present invention and strong magnetic-gravity separation-anion reverse flotation process are characterized in that comprising the following steps:

[0026] 1) Firstly, the poor hematite with a grade of 22-25% and a particle size of 0-12 mm is fed into the primary grinding until the content of -200 mesh particle size reaches 60% in the primary classification overflow,

[0027] 2) A grading overflow is fed into the medium magnet, the concentrate of the medium magnet is fed into the strong magnet, and the tailings of the medium magnet are returned to a grinding,

[0028] 3) The strong magnetic concentrate is given into coarse and subdivided grades, the strong magnetic tailings grade is <9%, and the strong magnetic tailings are discarded,

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com