Sand match vent drilling device

A technology of air holes and sand tires, used in boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve problems such as low efficiency, damage to castings, scrap castings, etc. Inefficiency, yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

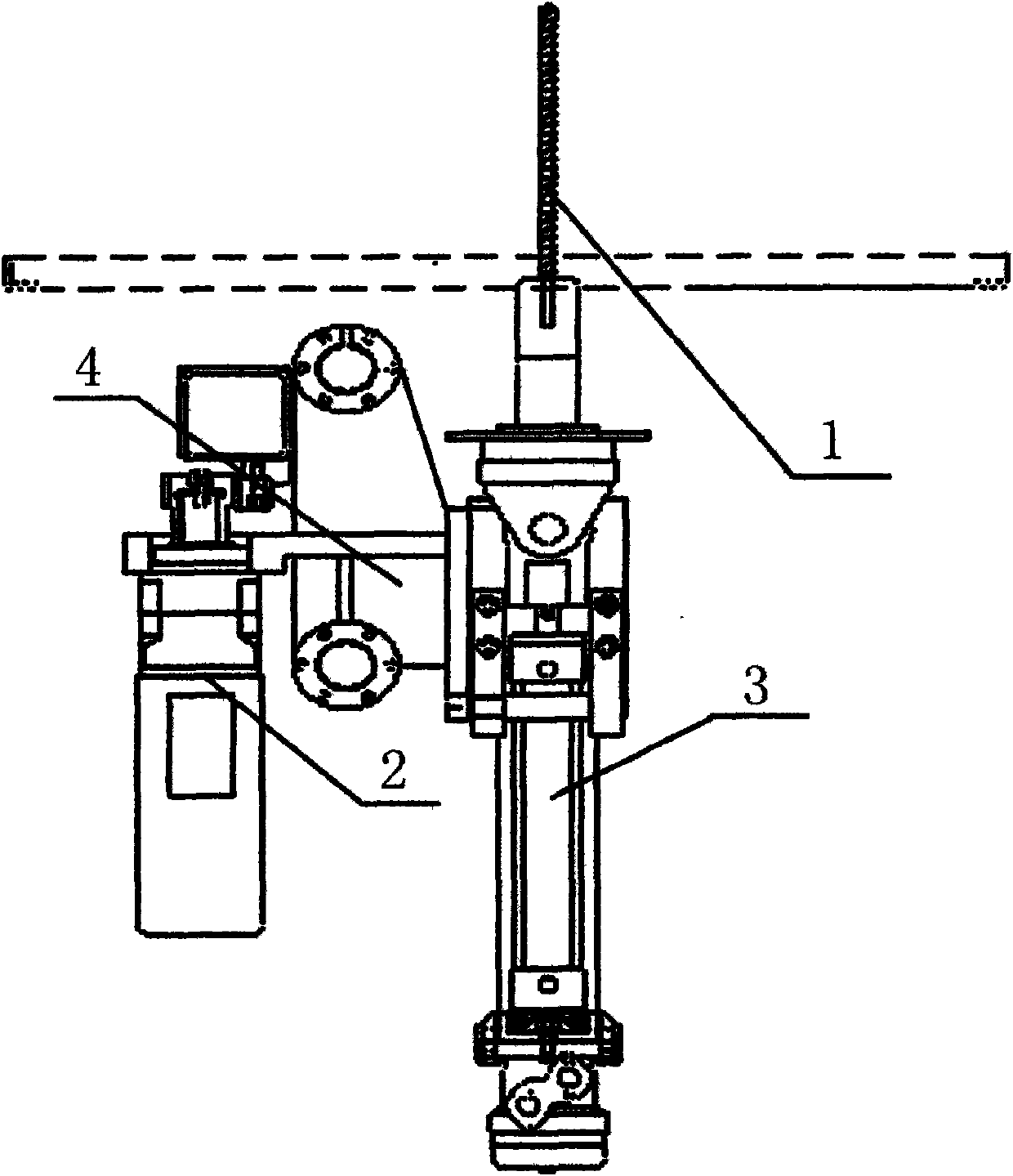

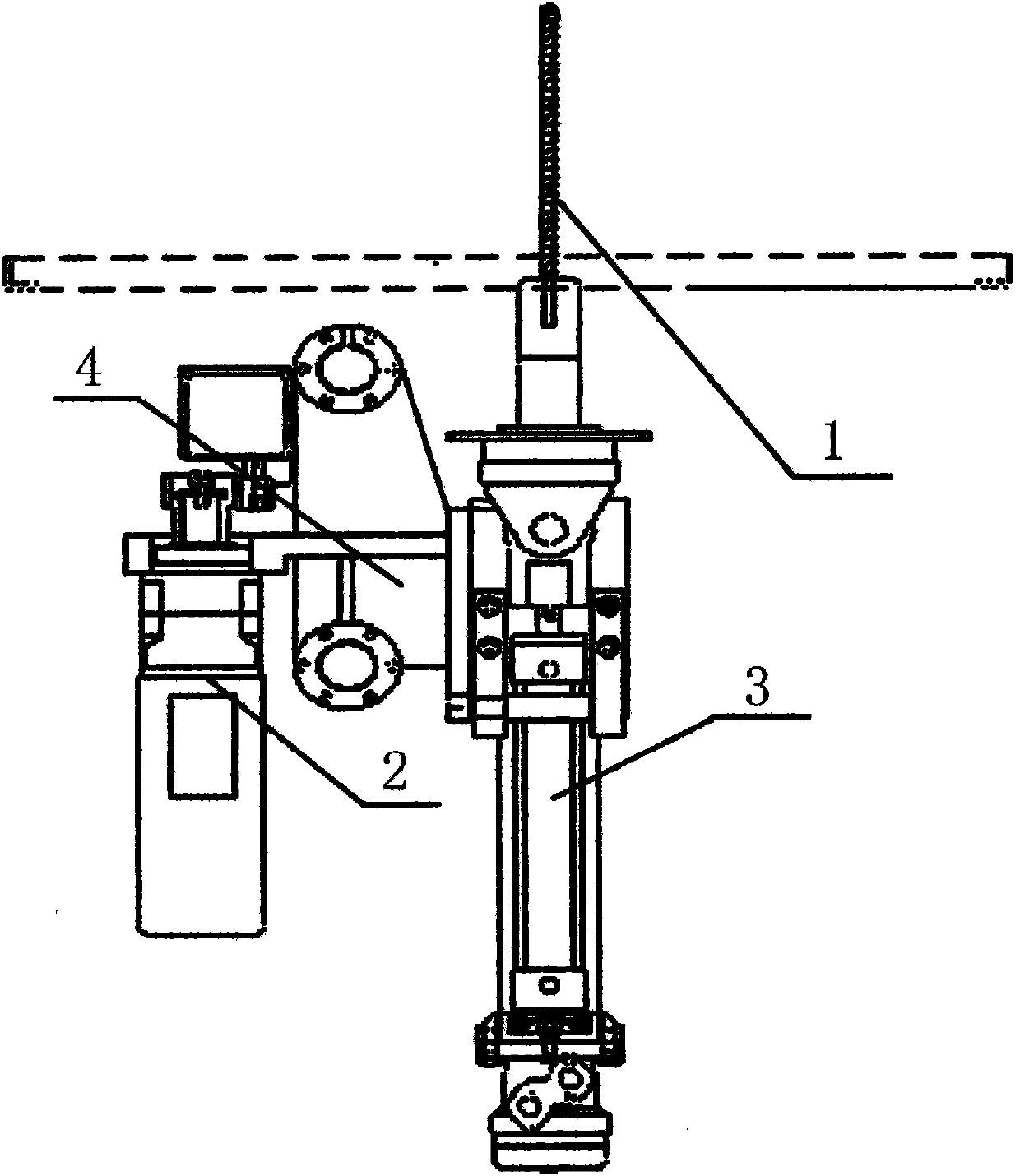

[0013] like figure 1 The shown sand tire air hole drilling device includes a drill bit 1, and the drill bit 1 realizes control of the feed depth at the feed position under the drive of the lift motor 4. For example, the drill bit feed depth can be set according to the thickness of the tire wall of the sand tire, In order to ensure that the pore depth is not too deep or too shallow, so as to achieve the required ventilation effect.

[0014] In particular, the device drives and controls the reciprocating motion of the drill bit 1 within a lateral limited range by setting the servo motor 2, thereby realizing the servo motor to control the movement of the drill bit device with the lifting motor in four directions, front, rear, left, right, and right within the working range.

[0015] In addition, a hydraulic oil cylinder 3 is also connected to the rear of the drill bit 1, so as to better realize the reasonable control of the drill bit according to the energy provided by the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com