Novel flexible overturning fixture for multiple vehicle frames

A technology for flipping fixtures and multiple models, applied in manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of unreliable automatic flipping work, unbalanced force on flipping devices, damage to equipment, etc., so as to improve reliability and safety. The effect of stability, wide range of practicality and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

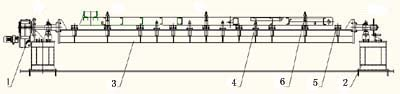

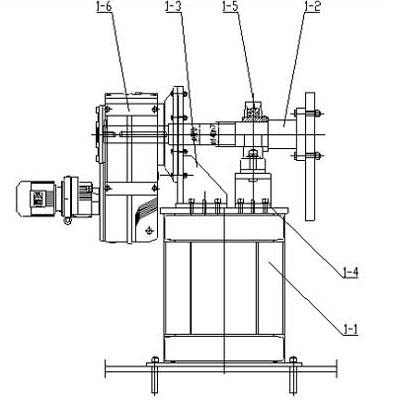

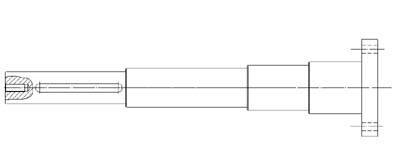

[0018] Below in conjunction with accompanying drawing, the present invention will be further described: as Figure 1-7 As shown, the new multi-vehicle frame flexible overturning fixture is composed of an automatic overturning device 1, an automatic follow-up overturning device 2, a overturning frame 3, a top tightening mechanism 4, a supporting device 5, and a pressing device 6. It is characterized in that: automatic overturning The device 1 is composed of a support 1-1, a turning shaft 1-2, a support 1-3, a bearing 1-5, a bearing seat 1-4, and a driving motor 1-6, wherein the support 1-1 is fixedly connected with a support 1 -3 and bearing block 1-4, one end of turning shaft 1-2 is connected with drive motor 1-6 through support 1-3 and bearing block 1-4, and the other end is connected with turning frame 3; Follow-up bracket 2-1, follow-up rotation shaft 2-2, follow-up support 2-3, follow-up bearing seat 2-4, anti-retraction wheel 2-5, follow-up bearing 2-6, wherein follow-up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com