Automatic aligning lateral clamping pneumatic pipe gripping device

A self-aligning and pipe grab technology, which is applied in textiles and papermaking, etc., can solve the problems of having to be replaced accordingly, the pipe grab cannot be pulled out, and the long stroke, so as to save auxiliary time, prolong the service life, and open the gear reasonably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

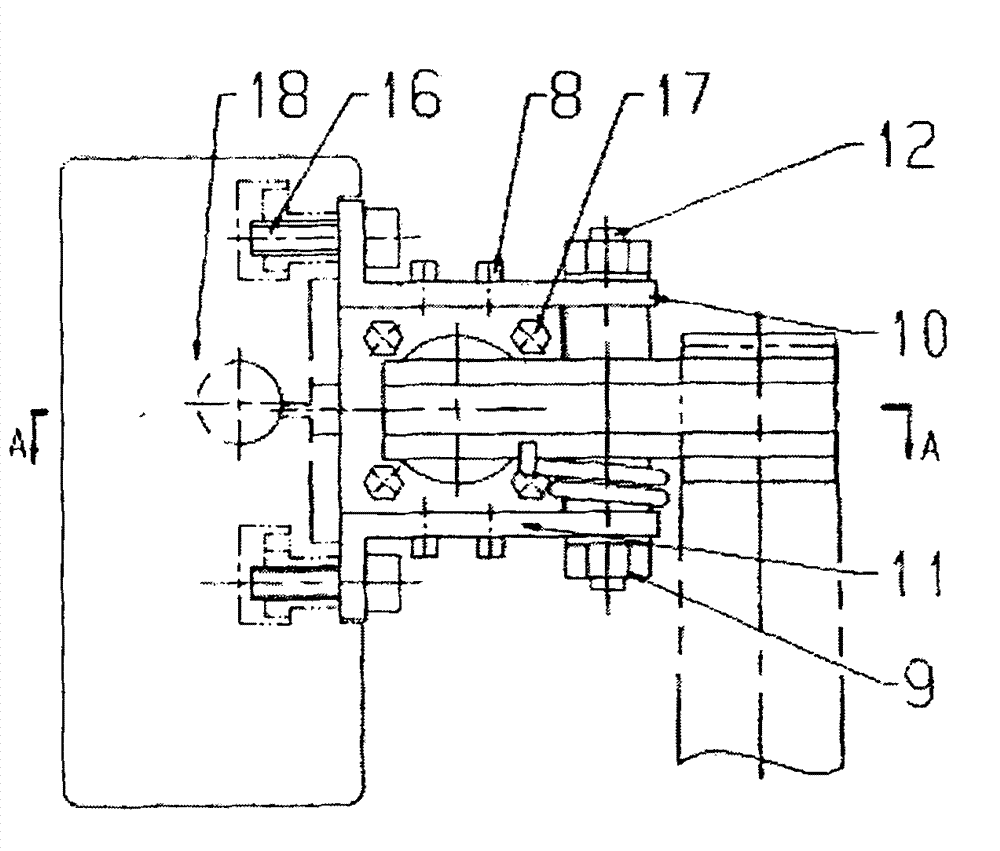

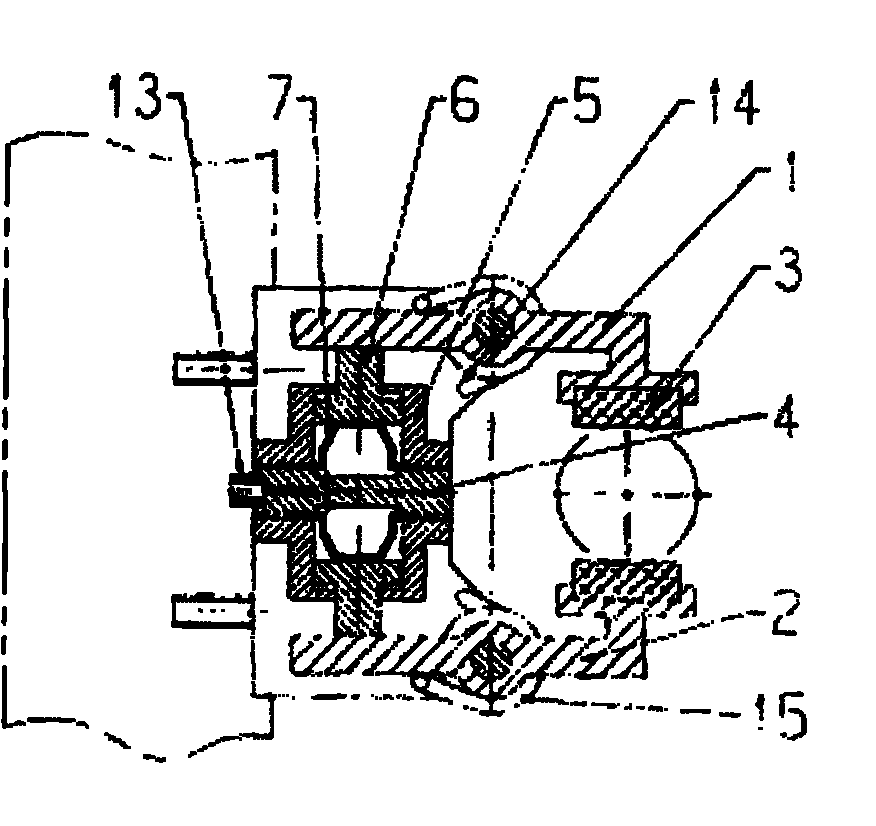

[0013] A self-aligning side clamping pneumatic pipe grabber, such as figure 1 As shown, it includes a first jaw 1, a second jaw 2, an elastic body 3, a cylinder body 4, a cylinder head 5, a piston 6, an elastic film 7, a positioning pin 8, a nut 9, an upper bracket 10, and a lower bracket 11 , pin shaft 12, gasket 13, right-handed spring 14, left-handed spring 15, first screw 16, second screw 17 and air frame 18, the front ends of the first jaw 1 and the second jaw 2 are respectively embedded with an elastic body 3. Both sides of the cylinder block 4 are respectively connected with the cylinder head 5, fastened by the second screw 17, an elastic film 7 is arranged between the cylinder block 4 and the cylinder head 5, a piston 6 is arranged inside the cylinder head 5, and the cylinder body 4 is set Between the upper bracket 10 and the lower bracket 11, it is positioned by the positioning pin 8; the left-handed spring 15 and the right-handed spring 14 are respectively arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com