Method for using model and automatic device to realize automatic and remote management of hydropower station

A technology of automation equipment and remote management, applied in electrical components, data processing applications, instruments, etc., can solve problems such as time-consuming and laborious, strong dependence on employee experience, and judgment is not necessarily the most accurate, so as to reduce labor costs and avoid experience uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

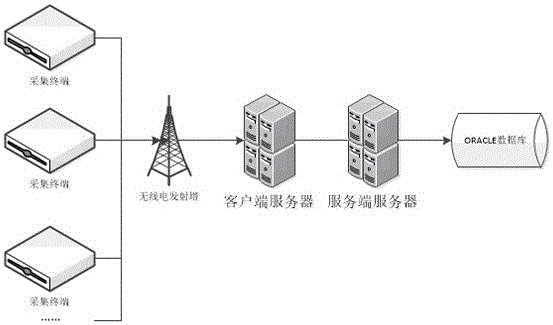

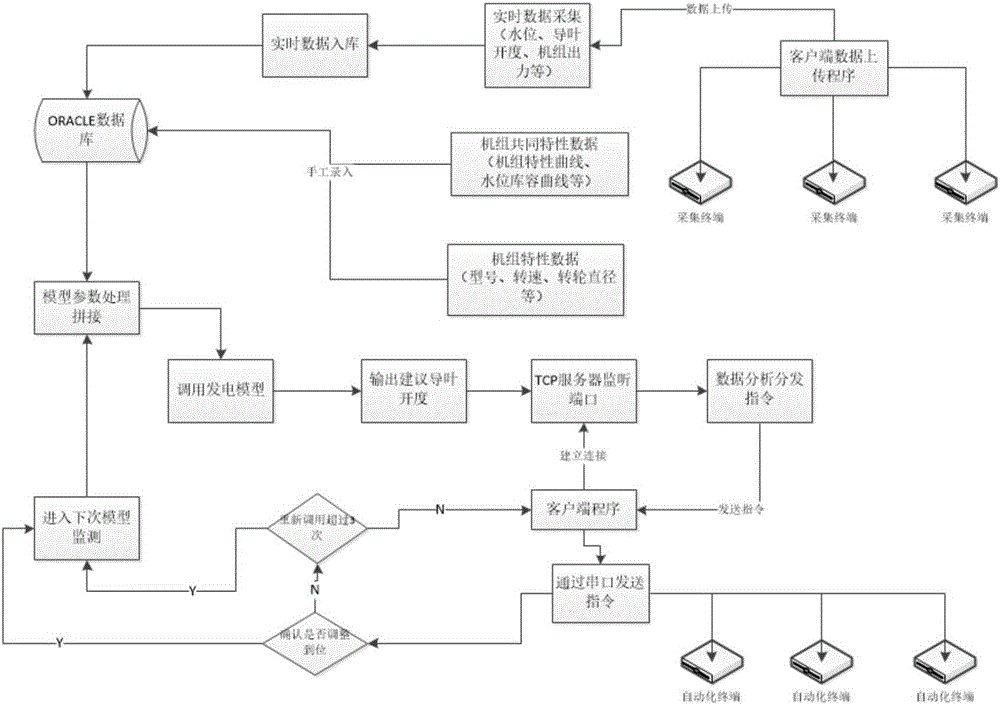

[0013] A method for realizing automatic remote management of a hydropower station by using a model and automation equipment, which includes the following steps: Step S1: Using a data acquisition terminal to collect rainfall, water level, guide vane opening, power generation and other real-time data of a hydropower station, according to different types data, configure the upload frequency of the data, and upload the monitoring data to the server in real time through the upload interface. After data screening and reasonable processing, the interface will collect obvious wrong data in the monitoring data (for example: the water level in front of the grid is negative or exceeds the calibration 1.5 times the flood level, it is obviously wrong data) After eliminating, finally save the data to the ORACLE database; Step S2: Call the model to calculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com