Optimum burden calculation method for electric furnace smelting

A technology of ingredient calculation and electric furnace smelting, which is applied in steelmaking production and casting fields, can solve the problems of low accuracy of manual calculation, difficulty in balancing cost and quality, and unstable quality control, so as to maintain continuous stability of the process, be easy to popularize, reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] [Example 1] The specific implementation method of the present invention will be described below by taking the optimization calculation of a specific casting smelting scheme as an example.

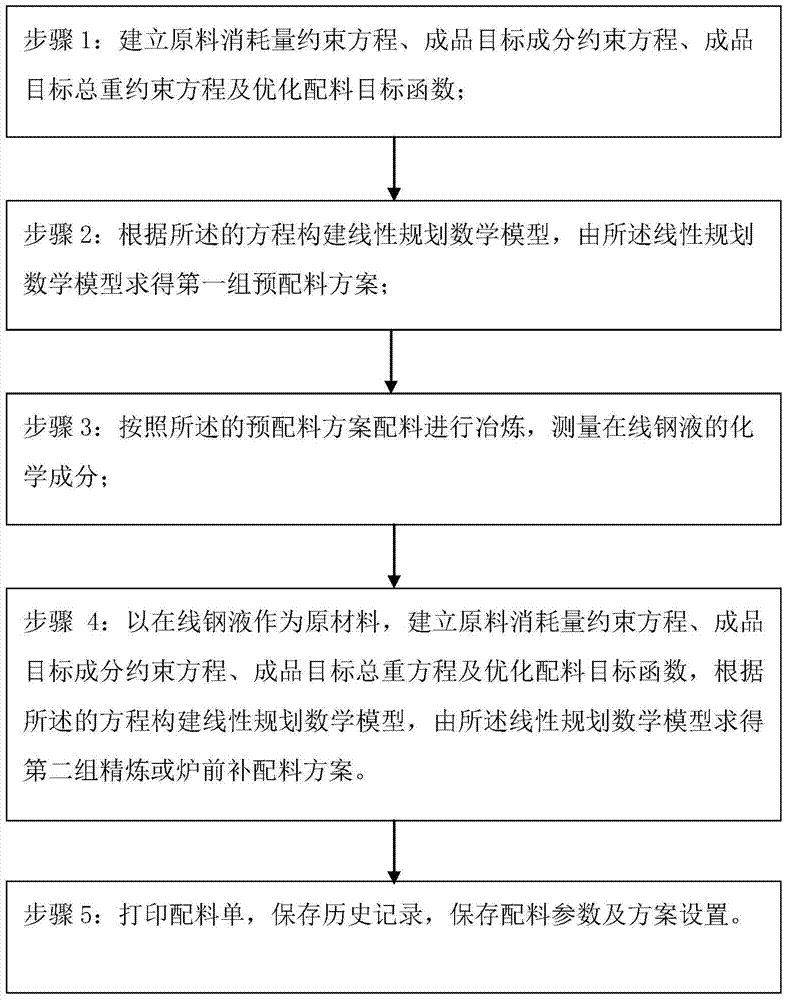

[0070] See figure 1 , is a schematic flow chart of the calculation method for optimizing the batching of electric furnace steelmaking described in this embodiment, including the following steps:

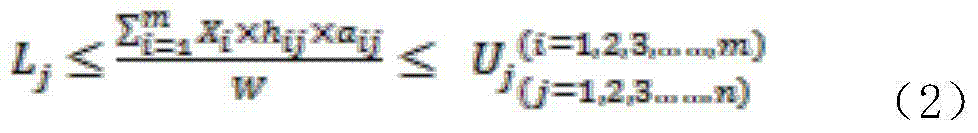

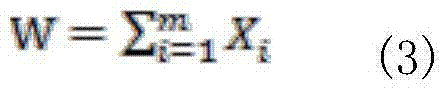

[0071] Step 1: Establish raw material consumption constraint equations, finished product target composition constraint equations, finished product target total weight constraint equations and optimize batching objective functions;

[0072] Step 2: Construct a linear programming mathematical model according to the equation, and obtain a group of pre-batching schemes by the linear programming mathematical model through "two-stage method" or computer software;

[0073] Step 3: Smelting according to the pre-batching scheme, and measuring the chemical composition of the online molten steel;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com