Method for reinforcing reinforced concrete beam by utilizing fiber reinforced concrete slab

A technology of reinforced concrete beams and fiber concrete, which is applied in building maintenance, construction, building construction, etc., can solve the problems of bond peeling, reinforcement material waste and reinforcement secondary, and achieve low cost, shorten the construction period, and improve the reinforcement process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

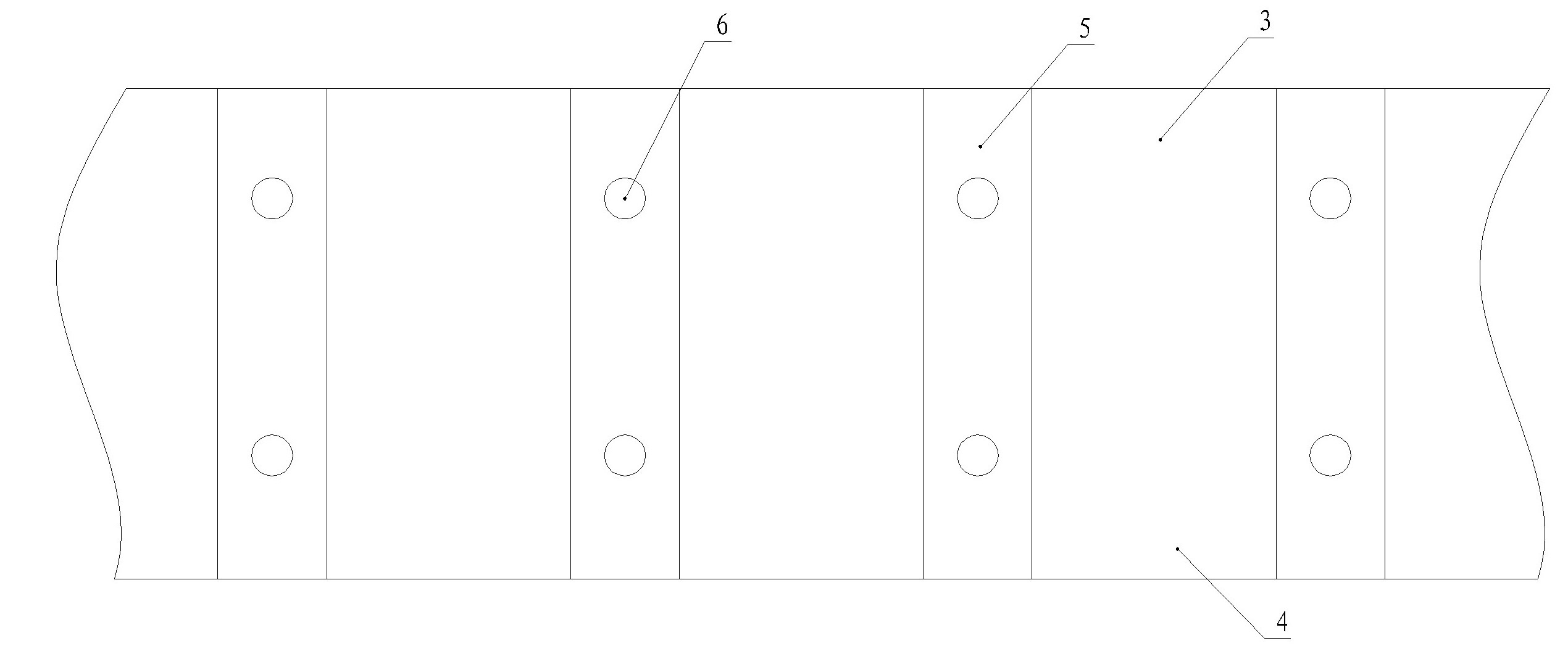

[0030] Embodiment: a kind of method for reinforcing reinforced concrete beam with fiber concrete slab among the figure, contains following steps,

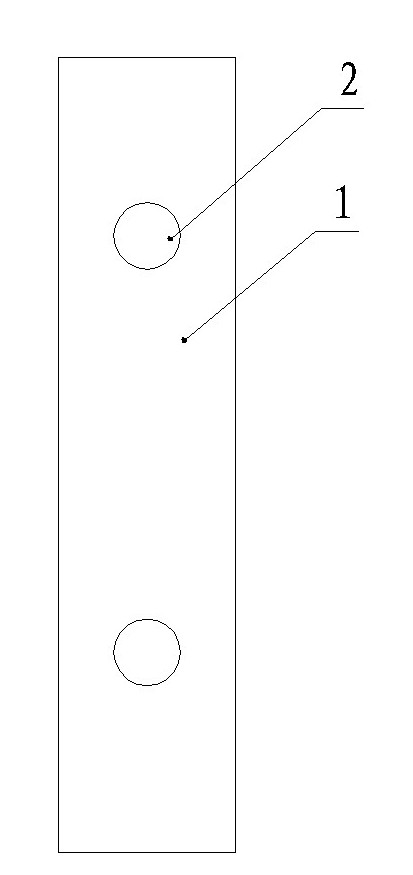

[0031] a. Prepare the steel fiber concrete slab and reserve holes on the slab;

[0032] b. Remove part of the concrete in the shear area of the reinforced concrete beam to be reinforced, form a notch, and implant steel bars in the notch;

[0033] The above steps a and b are in no particular order; then carry out

[0034] c. Embed the steel fiber concrete slab made in step a into the notch in step b, the joint surface of the steel fiber concrete slab and the reinforced concrete beam to be reinforced is bonded with building structure glue, and the steel bar described in the step B Pass through the holes described in step a and fasten with nuts at the ends of the bars.

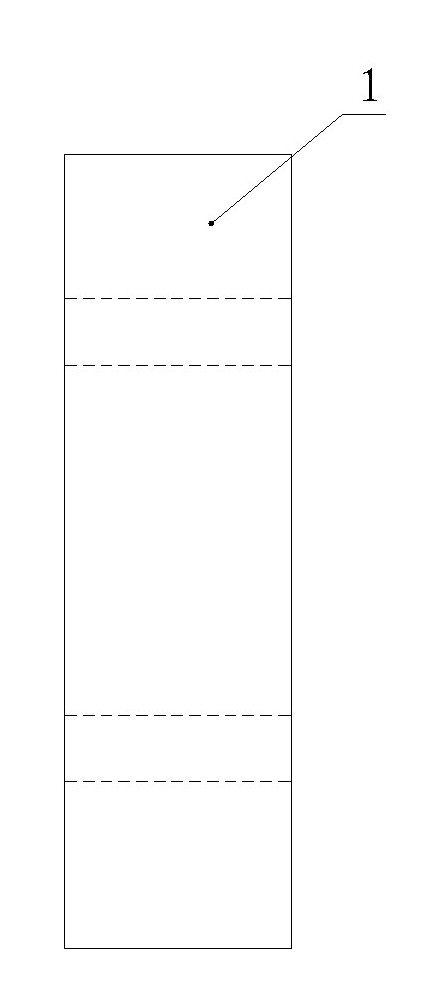

[0035] The steel fiber concrete slab is a high-strength steel fiber concrete slab made of cement, sand, silica fume, water reducing agent, and high-strength steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com