Body-free side detonation bidirectional perforator used for oil well

A technology for perforating guns and oil wells, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problems of perforating gun stuck in the casing, waste of high-quality steel, malignant accidents, etc., so as to save operating costs , Perforating operation is safe, and the effect of avoiding expansion gun stuck in the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

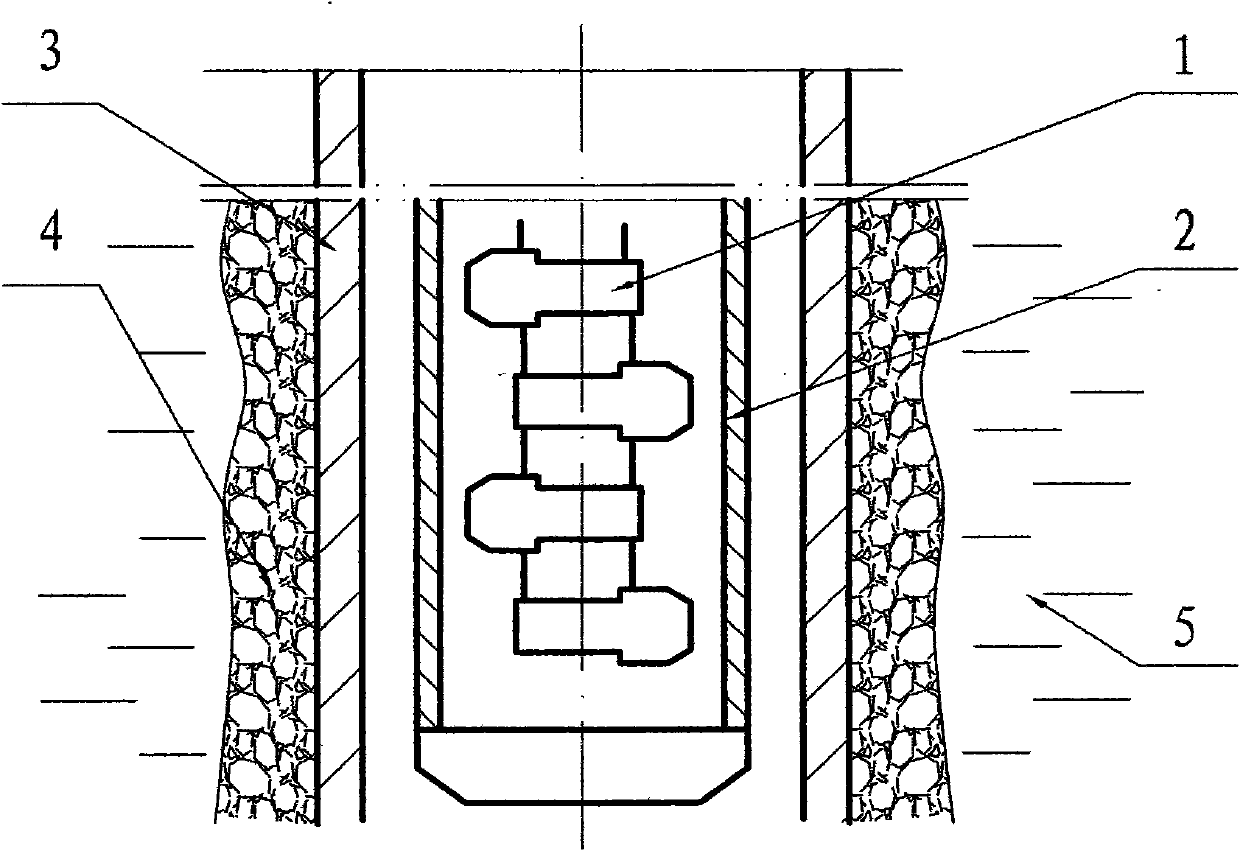

[0015] figure 1 It is a schematic diagram of oil well perforating operation. In oil exploration and production, it is usually necessary to drill wells on the oil-bearing land first, then lower the casing 3 into the well, then consolidate the casing 3 and the oil layer 5 with the cement sheath 4, and finally install the perforator The perforating gun 2 of 1 is lowered to a suitable position in the oil well. When the depth is calibrated, the perforating operation can be performed.

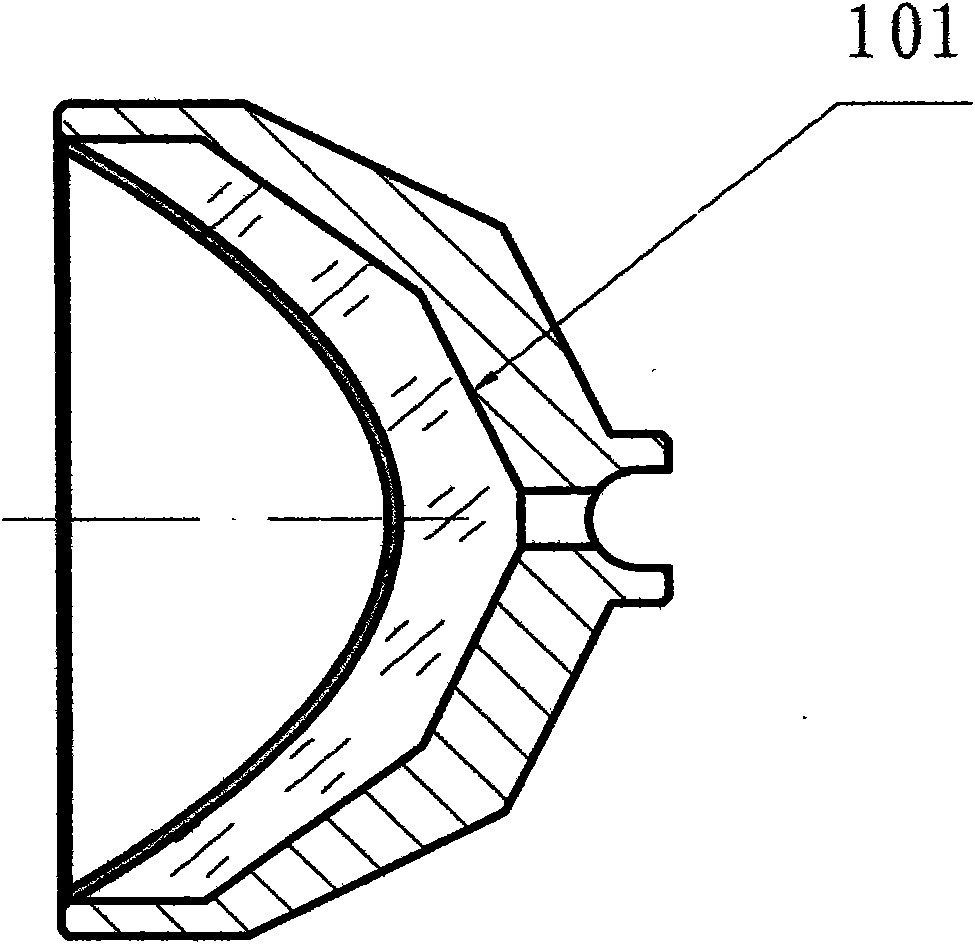

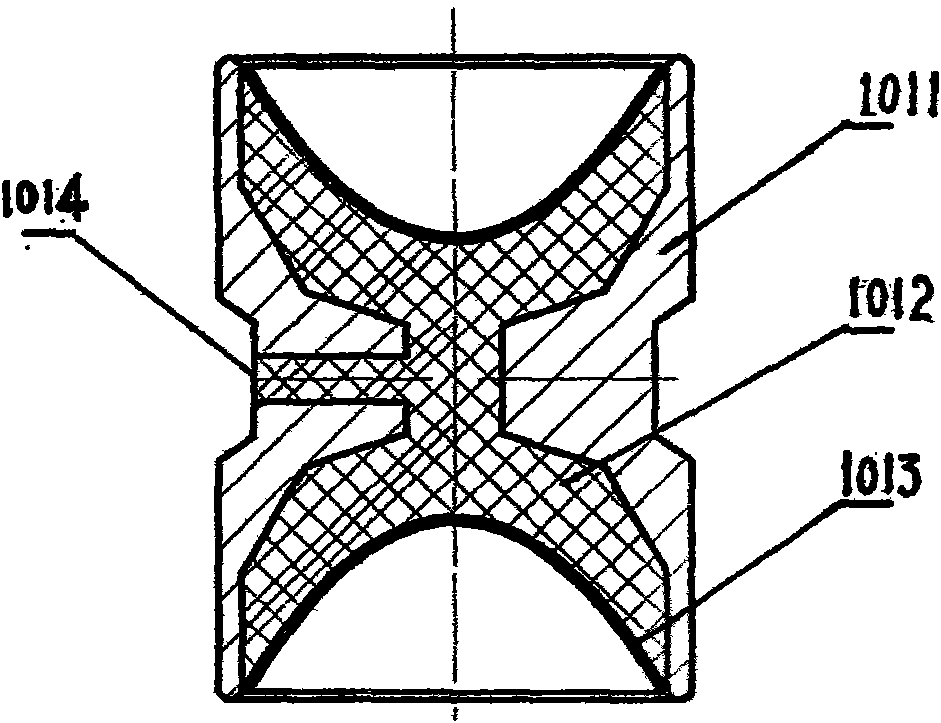

[0016] image 3 It is the structural diagram of the side detonation two-way perforator. The side detonation two-way perforator 101 is composed of two perforators coaxially and reversely installed together. In the figure, 1011 is the bullet casing, 1012 is the charge of the perforator, 1013 is the charge cover, and 1014 is the perforator. detonation hole.

[0017] Figure 4 It is an embodiment (I) of the present invention, and it is made up of a side detonation two-way perforator 101, detonating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com