Double-assembly adjustable pitch mine quarrying machine

A technology for quarrying and distance adjustment, which is used in open-pit mining, earthwork drilling, special mining, etc., can solve problems such as unreasonable structural design and inability to adjust the position of sawing machines, and achieves compact structure, ingenious design, and operation. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

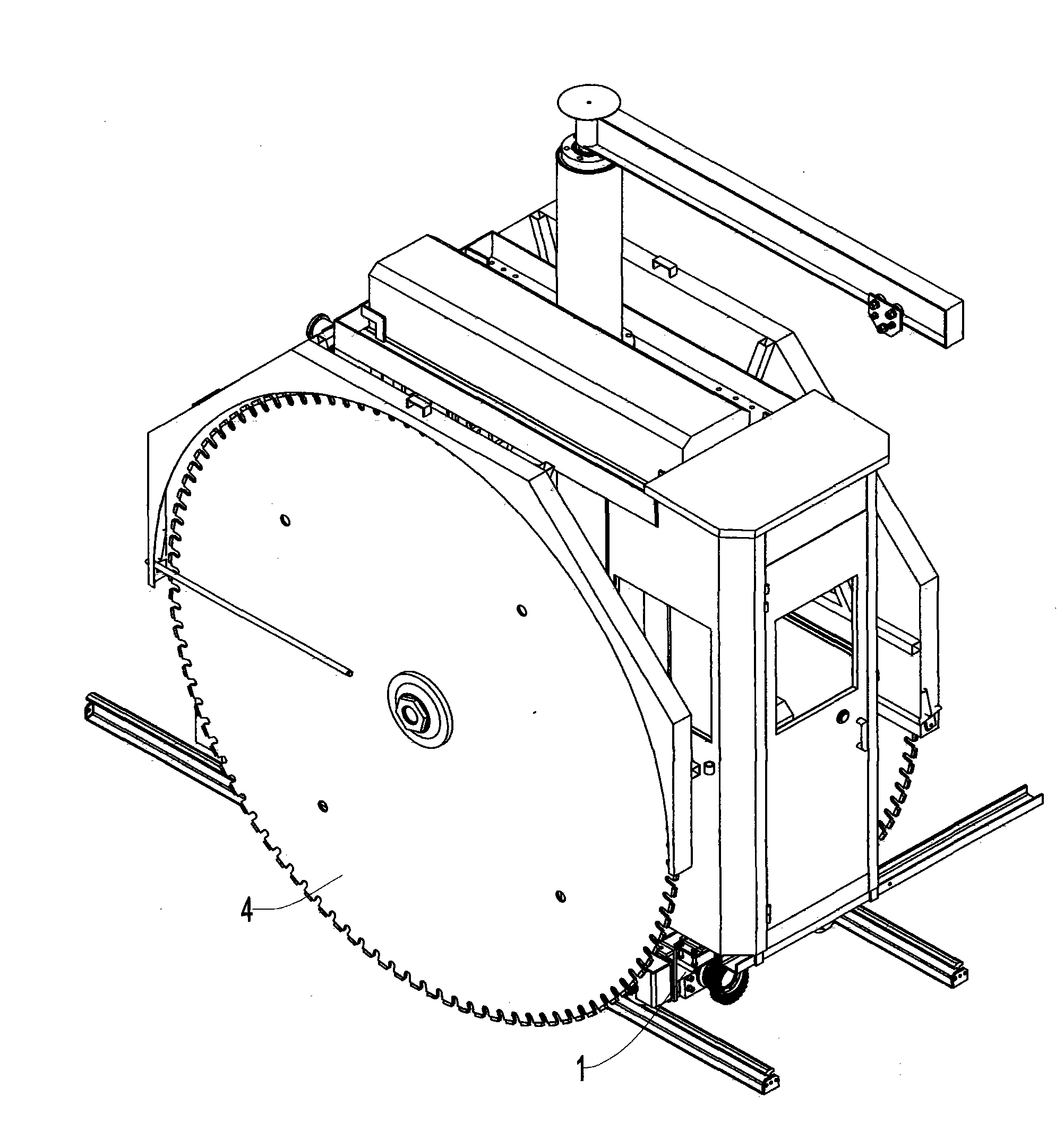

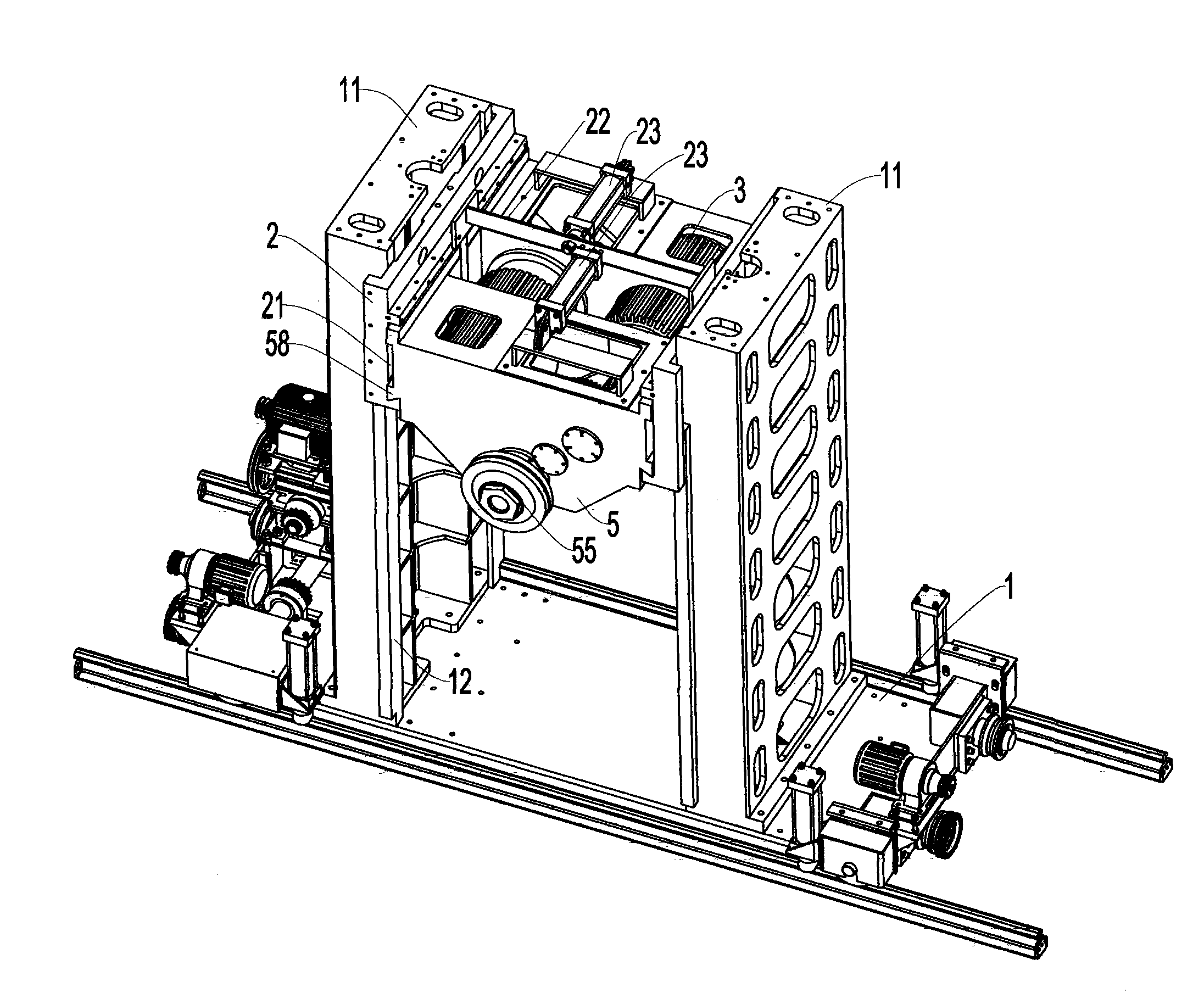

[0021] refer to figure 1 , figure 2 with image 3 , a double-piece adjustable distance mining quarry machine, including a machine base 1 capable of walking on the mine rail, two upright columns 11 standing on the machine base, a slide plate 2 sliding and pivoting on the column guide rail 12, and a sliding and pivoting In the saw machine between the two slide plates 2, a synchronous lifting drive mechanism is pivotally provided between the two slide plates 2 and the column 11 on the same side, and the synchronous lifting drive mechanism is a drive mechanism selected from a screw rod or an oil cylinder; the saw machine includes a motor 3 and a gearbox 5, and the saw blade 4 that is fixed on the gearbox output shaft.

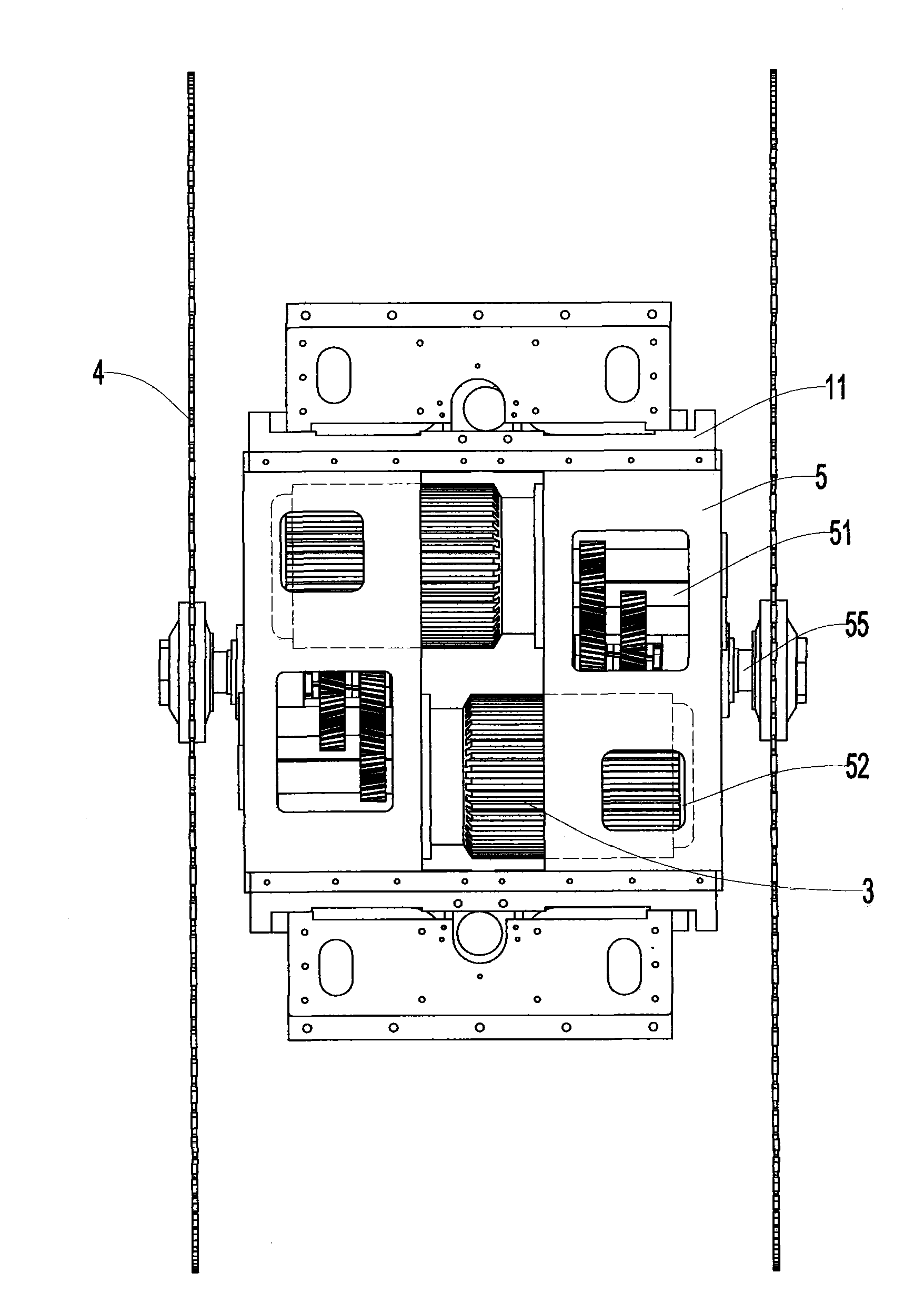

[0022] refer to Figure 4 The gearbox 5 is divided into a gear cavity 51 and a cavity 52. The gear cavity 51 is a three-axis structure, and a motor shaft 53, an intermediate shaft 54 and an output shaft 55 are distributed in sequence. The end face is direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com