Multi-cylinder diesel engine

A diesel engine, multi-cylinder technology, applied in the direction of engine components, combustion engines, engine cooling, etc., to achieve the effects of suppressing common rail thermal damage, suppressing common rail thermal damage, increasing fuel temperature, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

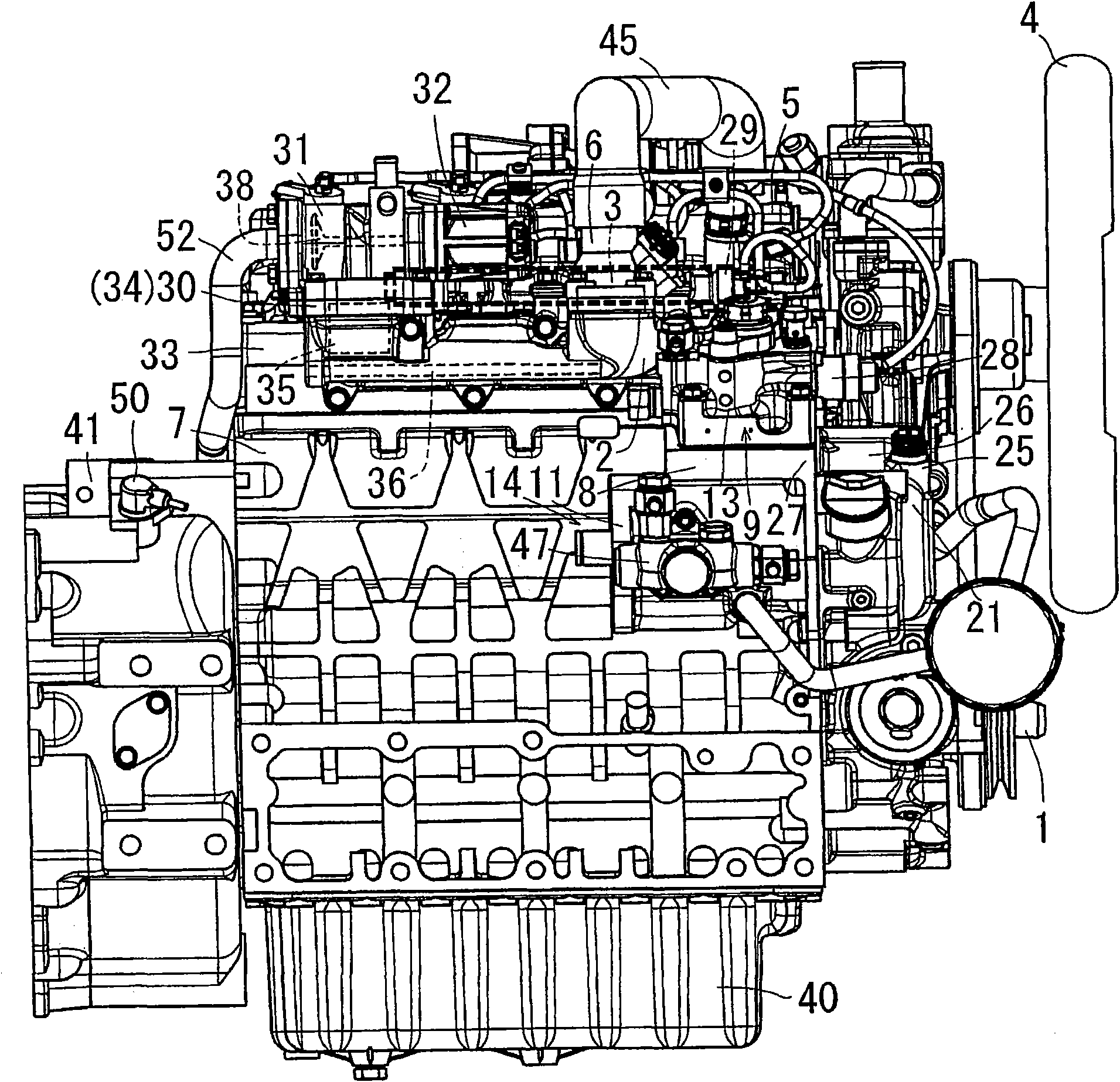

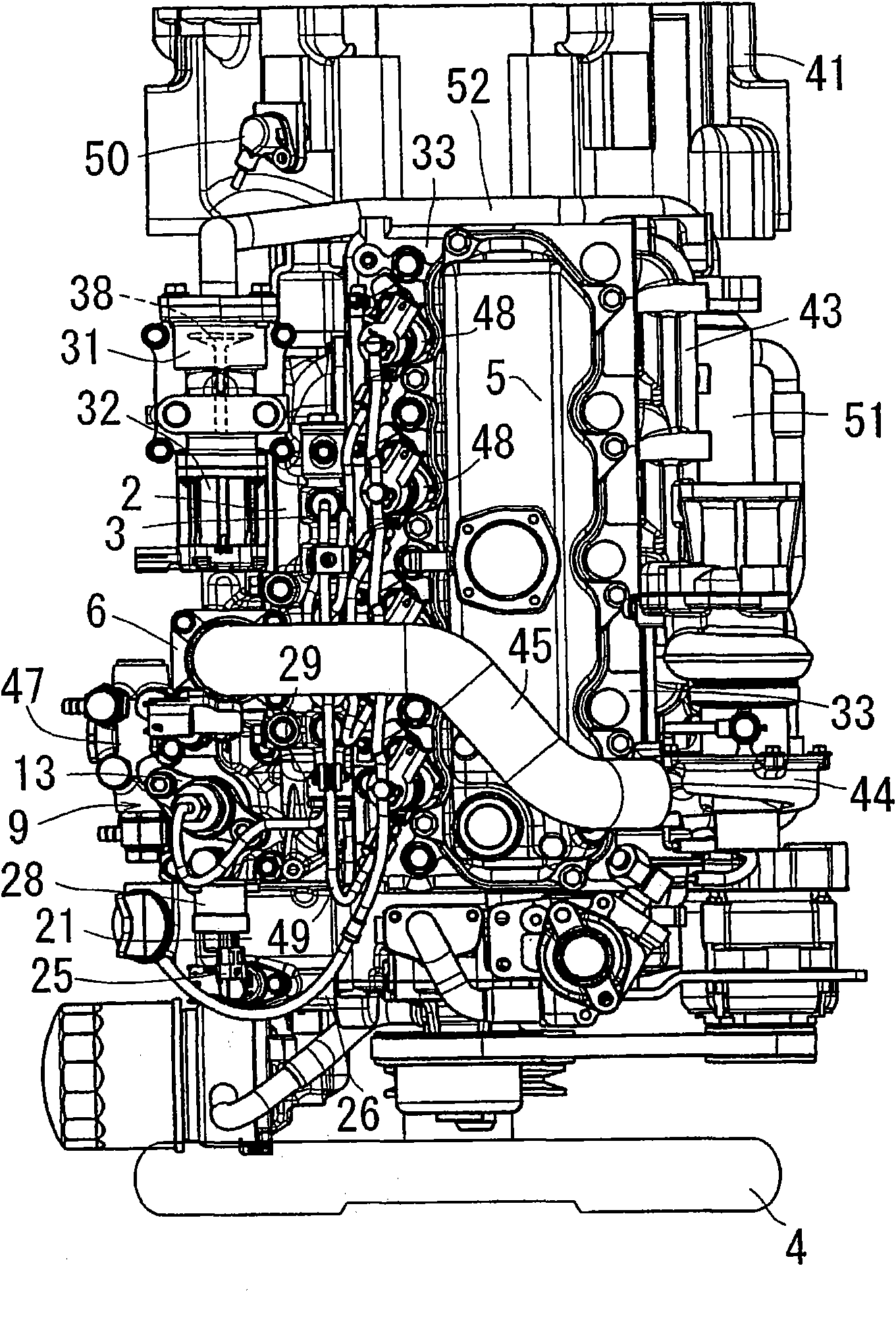

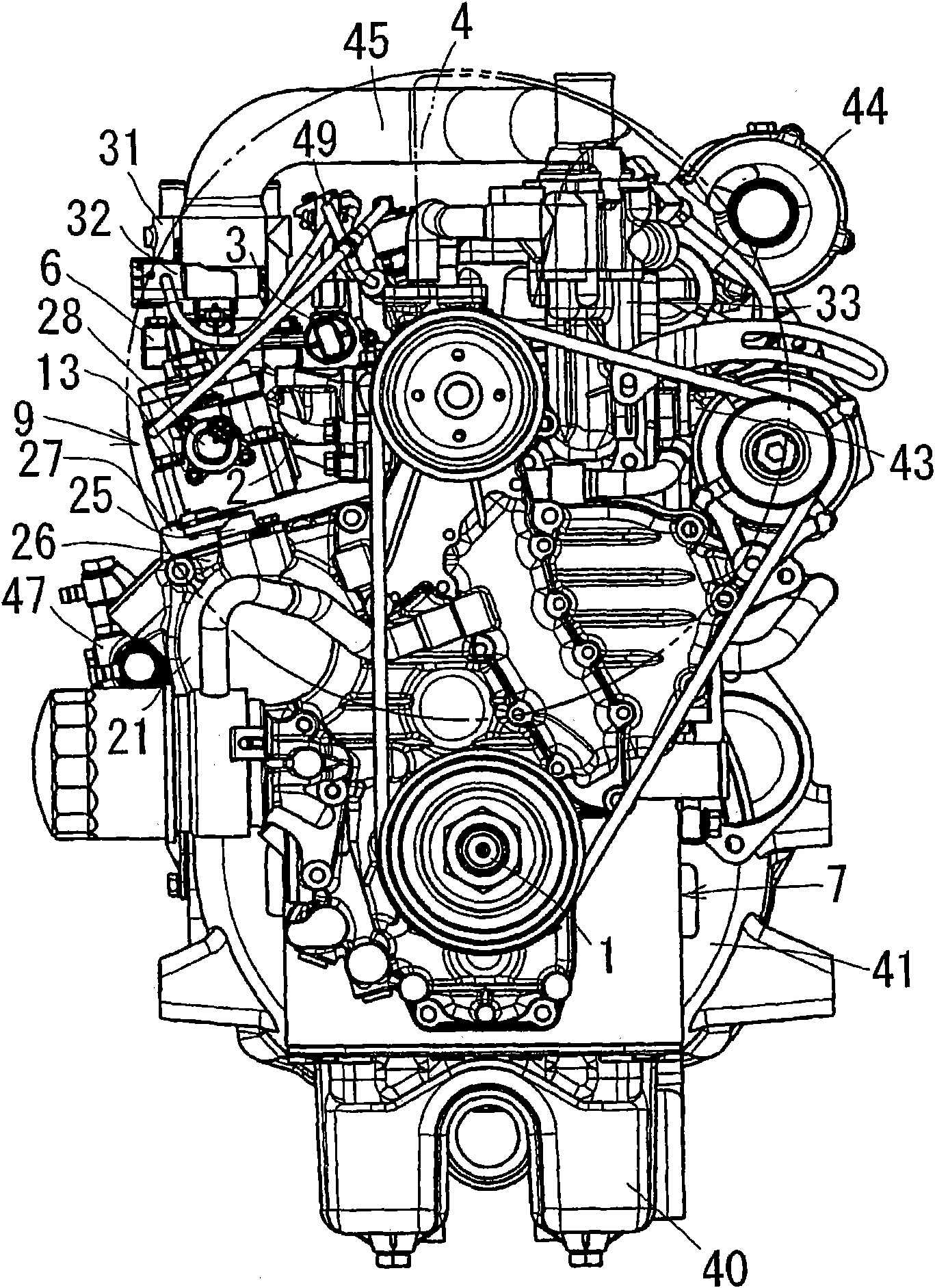

[0075] Such as image 3 As shown, with regard to the engine, a cylinder head 33 is assembled on the top of the cylinder block 7, a cylinder head cover 5 is assembled on the top of the cylinder head 33, an oil pan 40 is assembled on the bottom of the cylinder block 7, and an oil pan 40 is assembled on the bottom of the cylinder block 7. The gear box 21 is assembled in the part. Such as Figure 4 As shown, there is a flywheel housing 41 at the rear of the cylinder block 7 , and a flywheel 42 assembled on the crankshaft 1 is accommodated in the flywheel housing 41 .

[0076] Such as image 3 As shown, when viewed from the front of the engine, the intake manifold 2 is assembled on the left side of the cylinder head 33 , and the exhaust manifold 43 is assembled on the right side of the cylinder head 33 . A supercharger 44 is attached to an upper portion of the exhaust manifold 43 , and the intake air inlet portion 6 of the intake manifold 2 is supercharged from the supercharger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com