Water pump cavitation measuring method

A measurement method and cavitation technology, which is applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as errors and achieve the effect of improving certainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

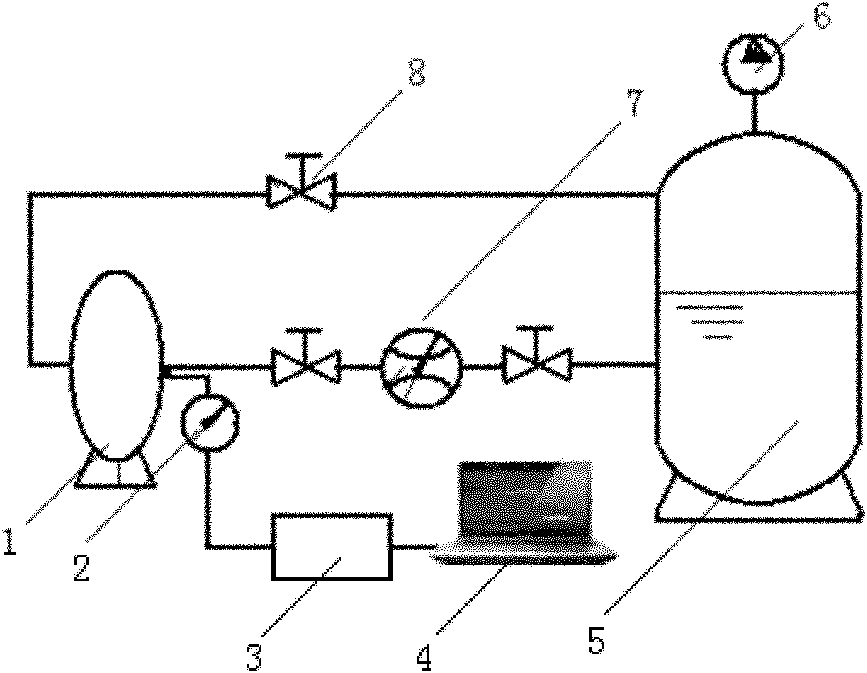

[0031] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

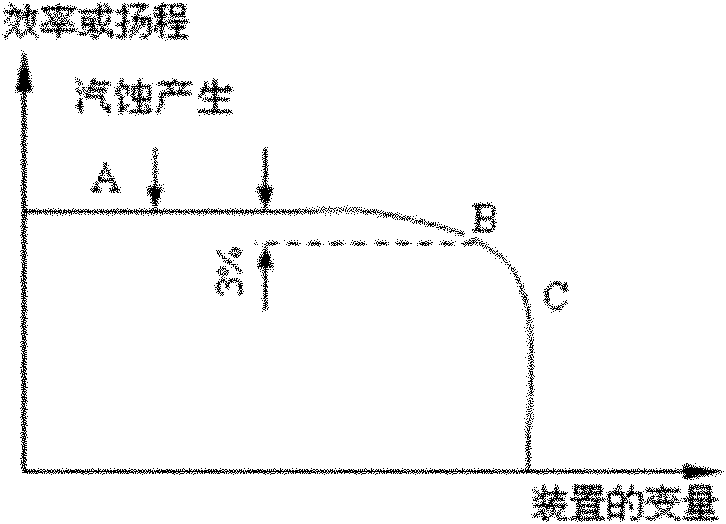

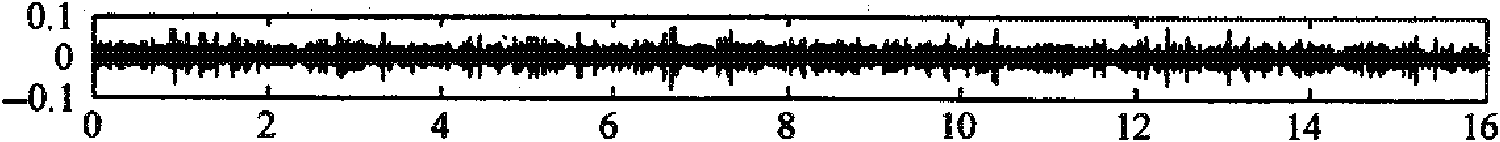

[0032] The parameters for detecting pump cavitation include noise signal of the pump, fluid pressure pulsation signal at the pump inlet, vibration signal, and pressure signal of the fluid in the pump. Among them, the fluid pressure pulsation signal at the pump inlet is an important parameter for cavitation detection. The test found that when the fluid is cavitated, the fluid pressure pulsation signal will show certain characteristics. Composite signals such as figure 2 As shown, there are many natural mode signals. The water pump cavitation measurement method of the present invention decomposes the composite signal into the sum of single-component signals with a certain intrinsic mode signal by using an Empirical Mode Decomposition (EMD) method. Since each component contains different frequency components and has different energy, a division of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com