Round-through continuously variable transmission

A continuously variable transmission, YTO stepless technology, applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of low power, complex structure, large investment and other problems of continuously variable transmissions, and achieve large transmission power and increased Great effect on personnel employment and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

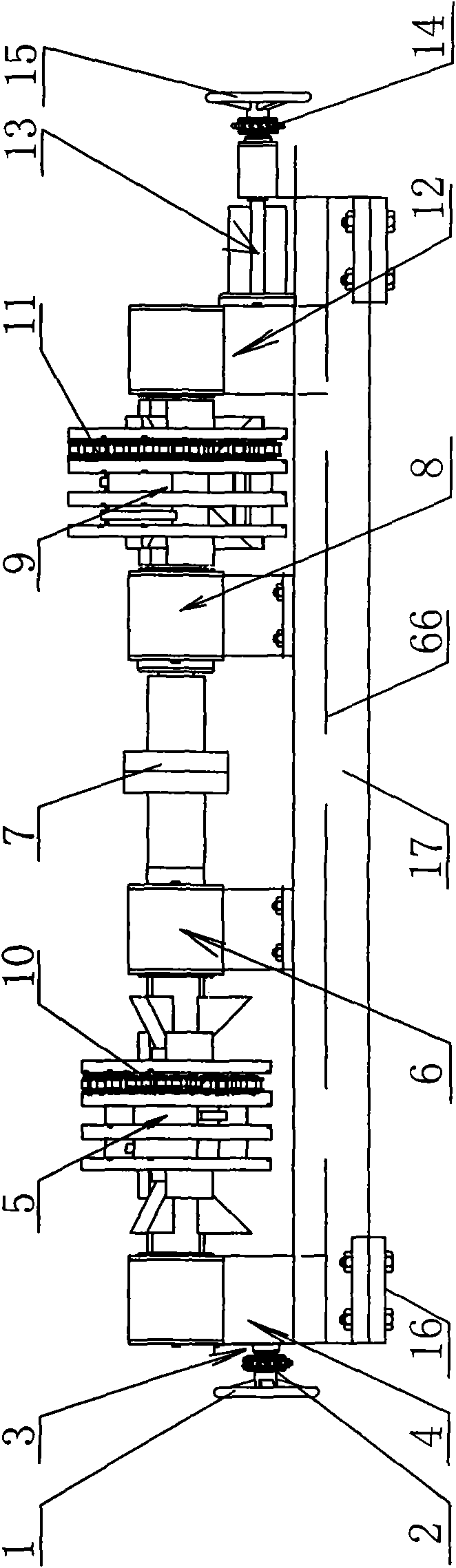

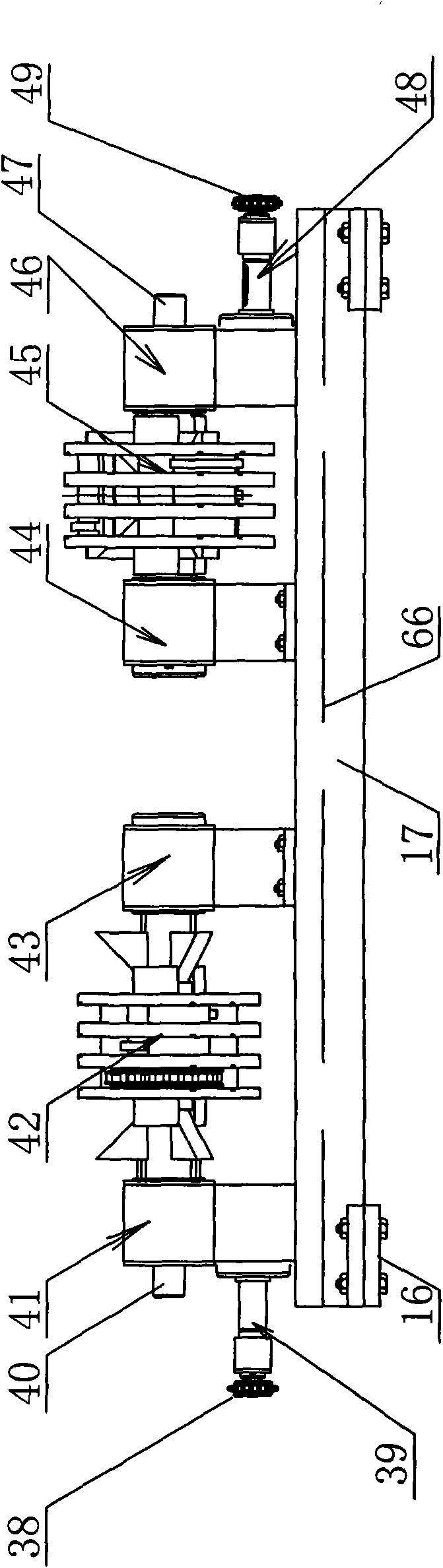

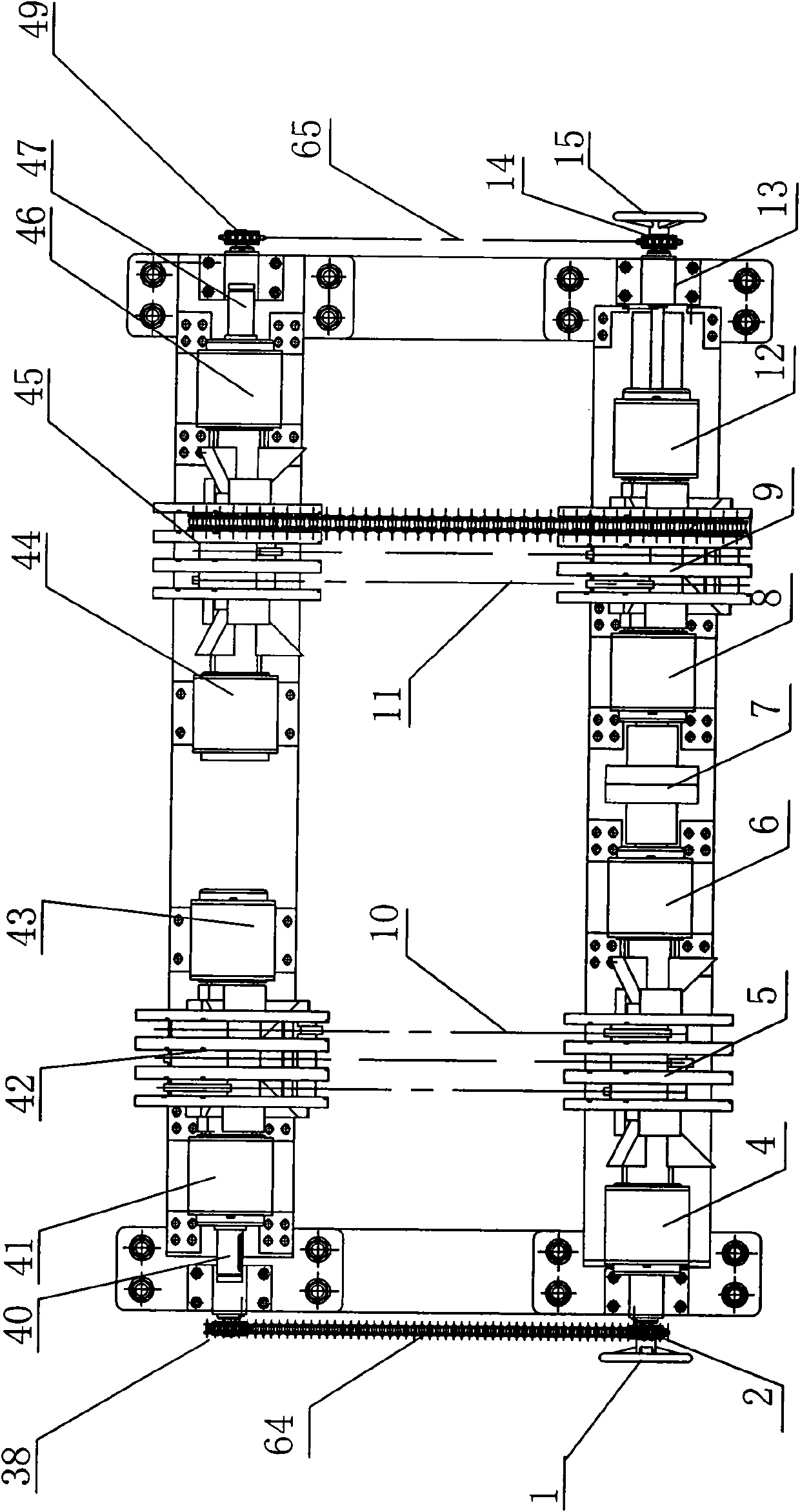

[0051] Yuantong continuously variable transmission, such as Figure 1-4 As shown, it includes an input mechanism, an output mechanism, a speed change mechanism, a guide rail 17 and a base 16; the guide rail 17 is a guide rail that is provided with a dovetail groove 66 in the middle of two strips, and the two guide rails 17 with the same structure are connected to the front and rear by screws. The two sides of two bases 16 with the same structure are fixedly connected; one side guide rail 17 is equipped with a speed change mechanism, and the other side guide rail 17 is equipped with an input mechanism and an output mechanism. End; the guide rail adopts dovetail channel 66 guide rail, and the material of the guide rail is cast iron. The dovetail channel 66 needs to be quenched.

[0052] The transmission mechanism, such as figure 1 , 3 , 18, including front and rear screw bearing parts 3, 13, sliding top seat parts 4, 12, large gear disc parts 9, front and rear positioning top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com