Method for modifying photoresisting materials by photosensitive nano-silica

A nano-silicon dioxide, photoresist material technology, applied in chemical instruments and methods, opto-mechanical equipment, optics, etc., can solve the problem of insignificant reduction of exposure energy, and improve the sensitivity of ultraviolet light energy and thermal expansion stability. the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example is a comparative example of not using photosensitive nano silicon dioxide to modify the photoresist material.

[0040] Dissolve 0.3g of the photoinitiating system (907 / ITX), 0.005g of the inhibitor hydroquinone in 1.095g of the active diluent tripropylene glycol diacrylate, add 8g of photosensitive alkali-soluble pure acrylate prepolymer, Add 0.1g of phthalocyanine blue, stir well, and screen-print it on the copper-clad board, pre-bake it at 75°C for 30min, expose it to a 500W ultraviolet lamp (exposure time 30s), and place it at 33°C±2°C with a mass concentration of 1%. NaCO 3 Develop in the solution (developing time 1min) to obtain a photoresist material that has not been modified by photosensitive nano silicon dioxide.

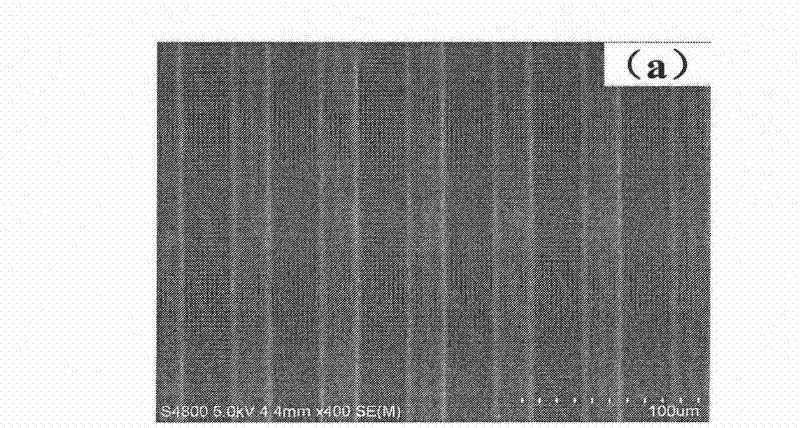

[0041] Such as figure 1 As shown, the resolution of the circuit pattern made of the photoresist material not modified by photosensitive nano-silica in Example 1 can reach 25 μm.

Embodiment 2

[0043] (1) Preparation of photosensitive nano-silica ester solution:

[0044]Add ethanol, distilled water and ammonia water into a three-necked flask at a molar ratio of 15:8:0.1:1 to ethyl orthosilicate, stir at 45°C and add 14.03 g of ethyl orthosilicate dropwise, and react at a constant temperature for 23 hours to obtain nanometer two Silica sol I. Add KH570 dropwise in 100g of nano-silica sol (molar ratio of KH570: tetraethyl orthosilicate = 4: 1), and react at 50°C for 3.5h to obtain photosensitive nano-silica sol II-M70SiO 2 . M70SiO 2 Mix with propylene glycol methyl ether acetate (the molar ratio of propylene glycol methyl ether acetate: ethanol = 1: 1), vacuum rotary evaporation at 30°C, remove ethanol and ammonia, and obtain photosensitive nano-silica M70SiO 2 Propylene glycol methyl ether acetate solution (60% solids content).

[0045] (2) Modification and preparation of photoresist materials:

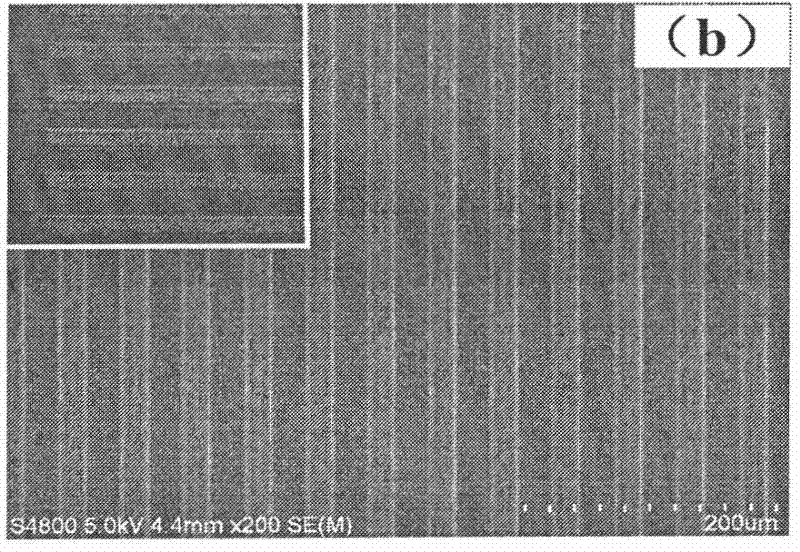

[0046] Dissolve 0.3g of the photoinitiating system (907 / ITX), 0.00...

Embodiment 3

[0049] (1) Preparation of photosensitive nano-silica ester solution:

[0050] Add ethanol, distilled water and ammonia water to a three-necked flask at a molar ratio of 20:12:0.2:1 to propyl orthosilicate, stir at 50°C and add 13.74 g of propyl orthosilicate dropwise, and react at a constant temperature for 24 hours to obtain nanometer two Silica sol I. Add KH570 (KH570: propyl orthosilicate molar ratio = 5.5: 1) dropwise in 100g of nano-silica sol, and react at 45°C for 4h to obtain photosensitive nano-silica sol II-M70SiO 2 . M70SiO 2 Mix with dimethyl mixed diacid (dimethyl mixed diacid: ethanol molar ratio = 1.1: 1), vacuum rotary evaporation at 27°C, remove ethanol and ammonia, and obtain photosensitive nano-silica M70SiO 2 Dimethyl mixed diacid solution (60% solids content).

[0051] (2) Modification and preparation of photoresist materials:

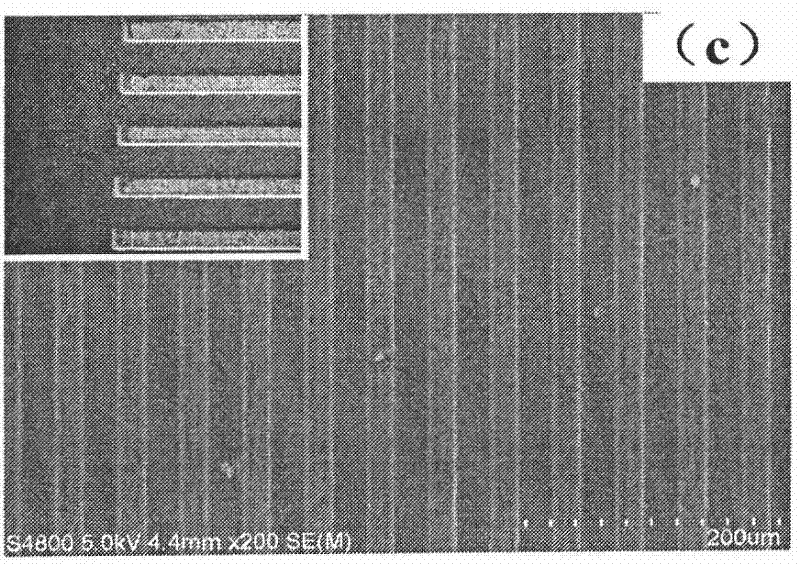

[0052] Dissolve 0.50g of the photoinitiator system (BCIM / EMK / NPG), 0.015g of the inhibitor p-hydroxyanisole in 1.485g of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com