Method for manufacturing GaAs-based metal oxide semiconductor (MOS) device

A technology of MOS devices and substrates, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that hinder the application of compound semiconductor MOSFETs, cannot obtain high-quality interface electrical properties, Fermi pinning, etc., and achieve Improve the interface quality, improve the electrical performance, the effect of small capacitance hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Substrate cleaning: The GaAs substrate was ultrasonically cleaned with acetone, ethanol, and isopropanol for 5 minutes in sequence, and then soaked in HCl aqueous solution with a volume ratio of 1:10 for 3 minutes.

[0023] 2) Substrate passivation: Clean the GaAs substrate with 8% volume ratio (NH 4 ) 2 Soak in S aqueous solution for 30 minutes;

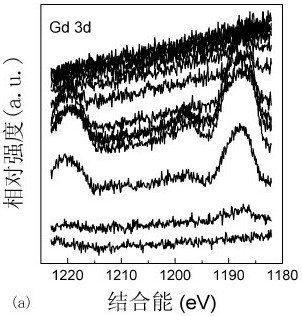

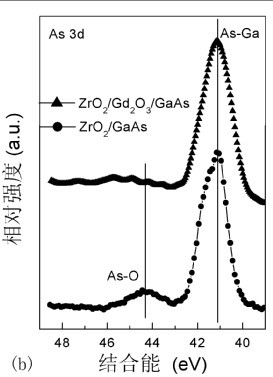

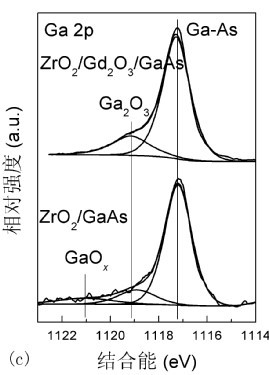

[0024] 3) MOCVD deposits a thin layer of Gd 2 o 3 Control layer process: put the passivated GaAs substrate into the MOCVD reaction chamber immediately, deposit Gd 2 o 3 Thin layer, the thickness of the thin layer is 2nm, the deposition temperature is 500 °C, and the metal source used is tetramethylheptadione gadolinium: Gd(DPM) 3 [DPM=tris(2,2,6,6-tetramethyl-3-5-heptanedionato)];

[0025] 4) ALD deposition of ZrO 2 Gate dielectric layer process: Put the processed GaAs substrate into the ALD reaction chamber, and set the ALD deposition parameters as:

[0026] Reaction chamber temperature: 300 °C;

[0027] Reaction...

Embodiment 2

[0036] 1) Substrate cleaning: The GaAs substrate was ultrasonically cleaned with acetone, ethanol, and isopropanol for 3 minutes, and then soaked in HCl aqueous solution with a volume ratio of 1:10 for 4 minutes.

[0037] 2) Substrate passivation: Clean the GaAs substrate with 40% volume ratio (NH 4 ) 2 Soak in S aqueous solution for 30 minutes;

[0038] 3) MOCVD deposits a thin layer of Gd 2 o 3 Control layer process: put the passivated GaAs substrate into the MOCVD reaction chamber immediately, deposit Gd 2 o 3 Thin layer, the thickness of the thin layer is 1nm, the deposition temperature is 500 °C, and the metal source used is tetramethylheptadione gadolinium: Gd(DPM) 3 [DPM=tris(2,2,6,6-tetramethyl-3-5-heptanedionato)];

[0039] 4) ALD deposition Zr-Al-O gate dielectric layer process: put the processed GaAs substrate into the ALD reaction chamber, and set the ALD deposition parameters as follows:

[0040] Reaction chamber temperature: 250 °C;

[0041] Reaction so...

Embodiment 3

[0045] 1) Substrate cleaning: The GaAs substrate was ultrasonically cleaned with acetone, ethanol, and isopropanol for 10 minutes in sequence, and then soaked in HCl aqueous solution with a volume ratio of 1:10 for 5 minutes.

[0046] 2) Substrate passivation: Clean the GaAs substrate with 20% volume ratio (NH 4 ) 2 Soak in S aqueous solution for 40 minutes;

[0047] 3) MOCVD deposits a thin layer of Gd 2 o 3 Control layer process: put the passivated GaAs substrate into the MOCVD reaction chamber immediately, deposit Gd 2 o 3 Thin layer, the thickness of the thin layer is 3nm, the deposition temperature is 500 °C, and the metal source used is tetramethylheptadione gadolinium: Gd(DPM) 3 [DPM=tris(2,2,6,6-tetramethyl-3-5-heptanedionato)];

[0048] 4) ALD deposition of HfO 2 Gate dielectric layer process: Put the processed GaAs substrate into the ALD reaction chamber, and set the ALD deposition parameters as:

[0049] Reaction chamber temperature: 350 °C;

[0050] Reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com