Laser processing method of workpiece

A laser processing method and a technology for processed objects, which can be applied to laser welding equipment, metal processing equipment, manufacturing tools, etc., and can solve problems such as deviation from the predetermined dividing line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

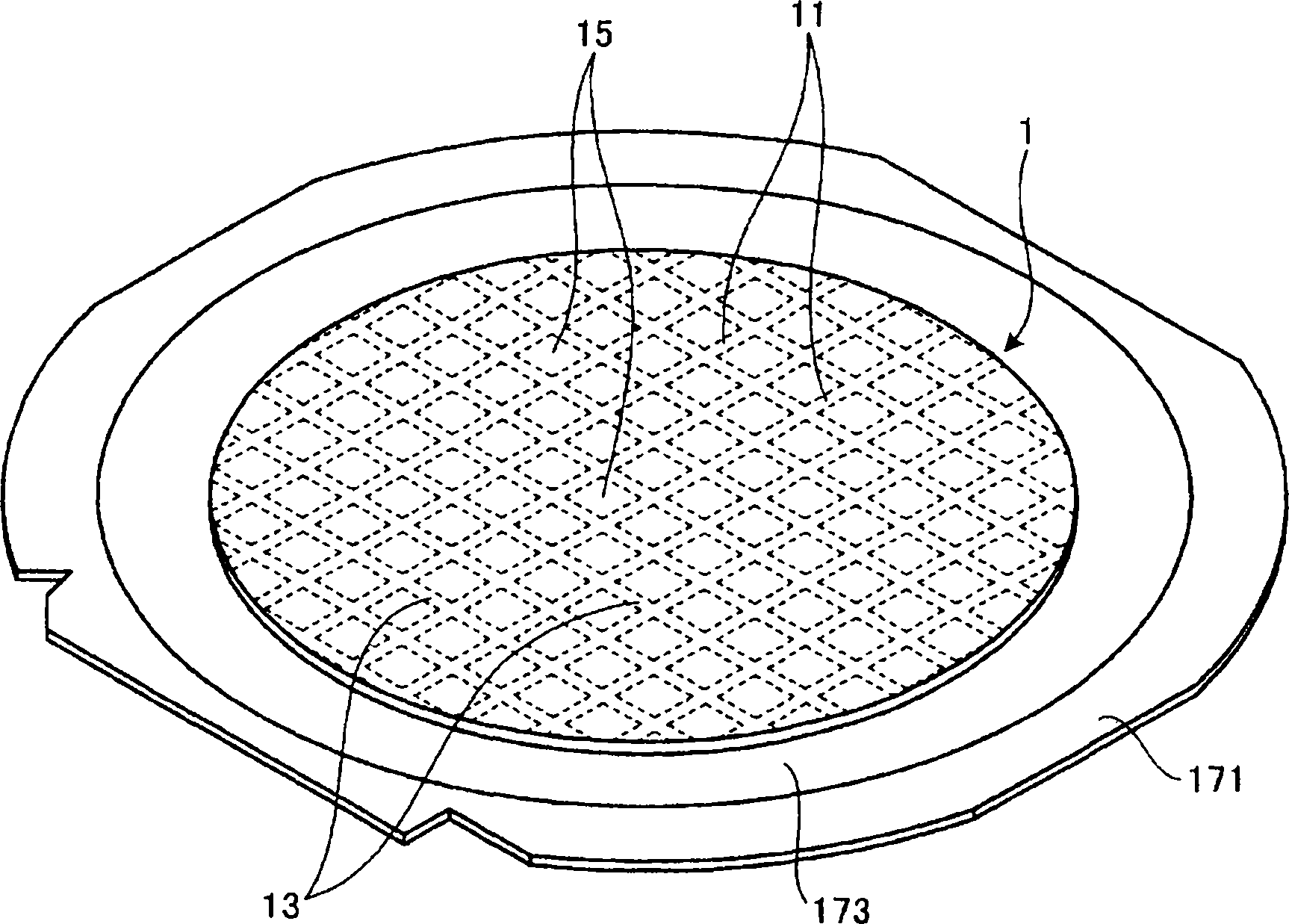

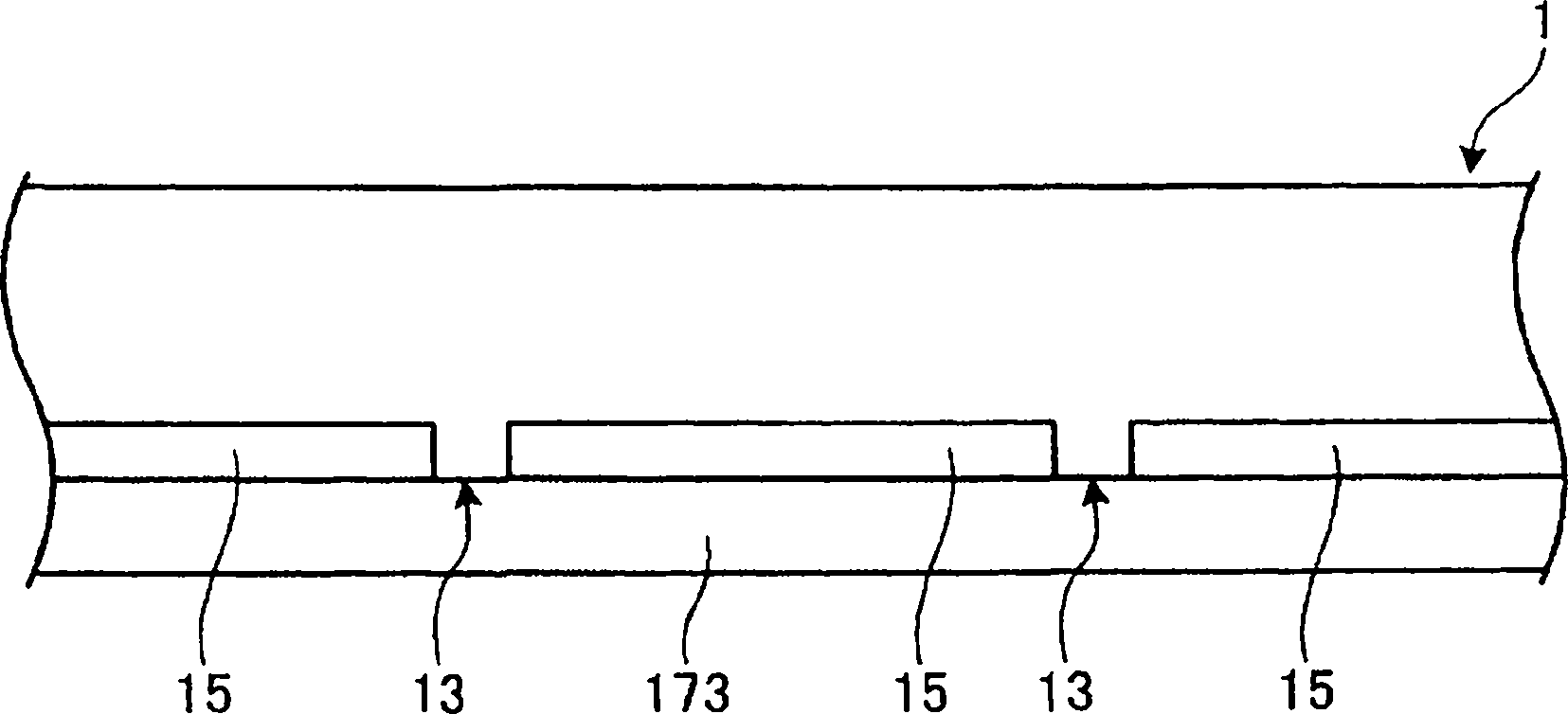

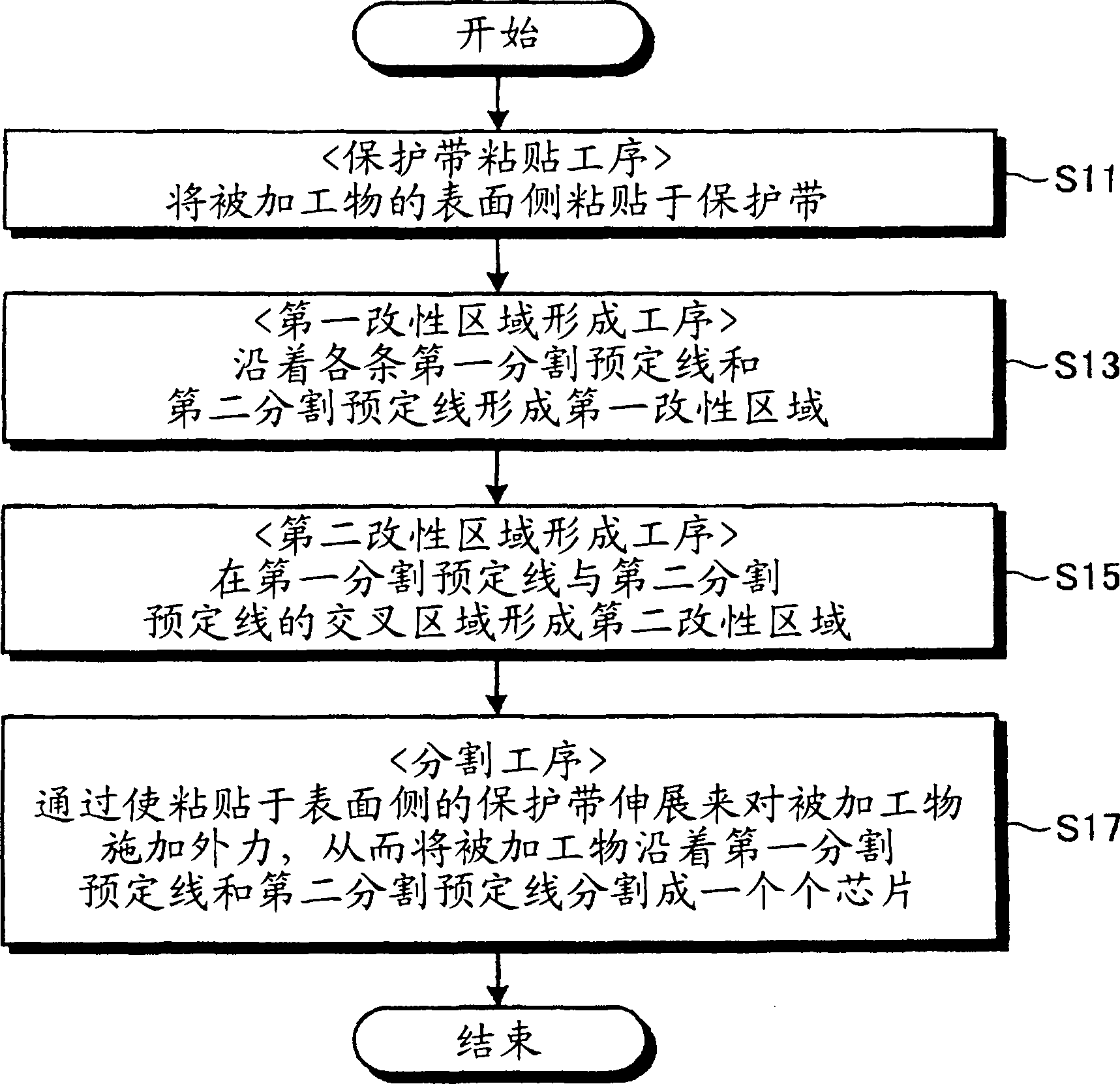

[0044] First, the workpiece to be processed in the processing method of Embodiment 1 will be described. figure 1 It is a perspective view showing a structural example of the workpiece 1 in the first embodiment. also, figure 2 It is a sectional view showing the inside of the workpiece 1 in the first embodiment. Such as figure 1 As shown, the workpiece 1 is configured to have a disc shape, and the first planned dividing line 11 and the second planned dividing line 13 are arranged in a grid on the surface side thereof, and the first planned dividing line 11 and the second planned dividing line 13 Functional elements 15 are formed in a plurality of rectangular areas divided by the second planned dividing line 13 . In addition, in the processing method of Embodiment 1, such as figure 1 with figure 2As shown, the workpiece 1 in the state supported by the ring frame 171 via the protective belt 173 made of a stretchable synthetic resin sheet is processed. More specifically, th...

Embodiment approach 2

[0081] In the first embodiment described above, when processing is performed by the processing device 2, the workpiece 1 is held with the back side exposed by the holding member 21, and the pulsed laser beam is irradiated from the rear side of the workpiece 1 to form the first laser beam. Modified area and second modified area. On the other hand, in Embodiment 2, the workpiece 1a is held with the surface side exposed by the holding member 21, and pulsed laser light is irradiated from the surface side of the workpiece 1a. The surface on the side irradiated with pulsed laser beams is not particularly limited, as long as it is formed sequentially from the modified region formed at a position farther from the surface on the side irradiated with pulsed laser beams in the thickness direction. Hereinafter, Embodiment 2 will be described in detail.

[0082] Figure 13 It is a perspective view showing a structural example of a workpiece 1a according to the second embodiment. also, ...

Embodiment approach 3

[0113] Figure 20 It is a perspective view explaining the structure of the semiconductor device 5b in Embodiment 3. Such as Figure 20 As shown, the semiconductor device 5 b in Embodiment 3 is configured by mounting a chip 10 b on a glass substrate 51 via an adhesive resin layer 53 . The chip 10 b is obtained by implementing the processing method described in the first embodiment or the second embodiment, and the chip 10 b is equivalent to the chip 10 in the first embodiment or the chip 10 a in the second embodiment. In addition, the adhesive resin layer 53 is, for example, an epoxy-based anisotropic conductive film (ACF: Anisotropic Conductive Film), which electrically and physically connects the glass substrate 51 and the chip 10 b by thermocompression bonding.

[0114] In the method of manufacturing the semiconductor device 5 b , first, an anisotropic conductive adhesive film used as the adhesive resin layer 53 is disposed on the glass substrate 51 . Then, the chip 10b i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com