Moving iron type low frequency acoustic generator

A technology of moving iron and sounder, which is applied in the direction of sensors, electrical components, etc., to achieve the effect of small size and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

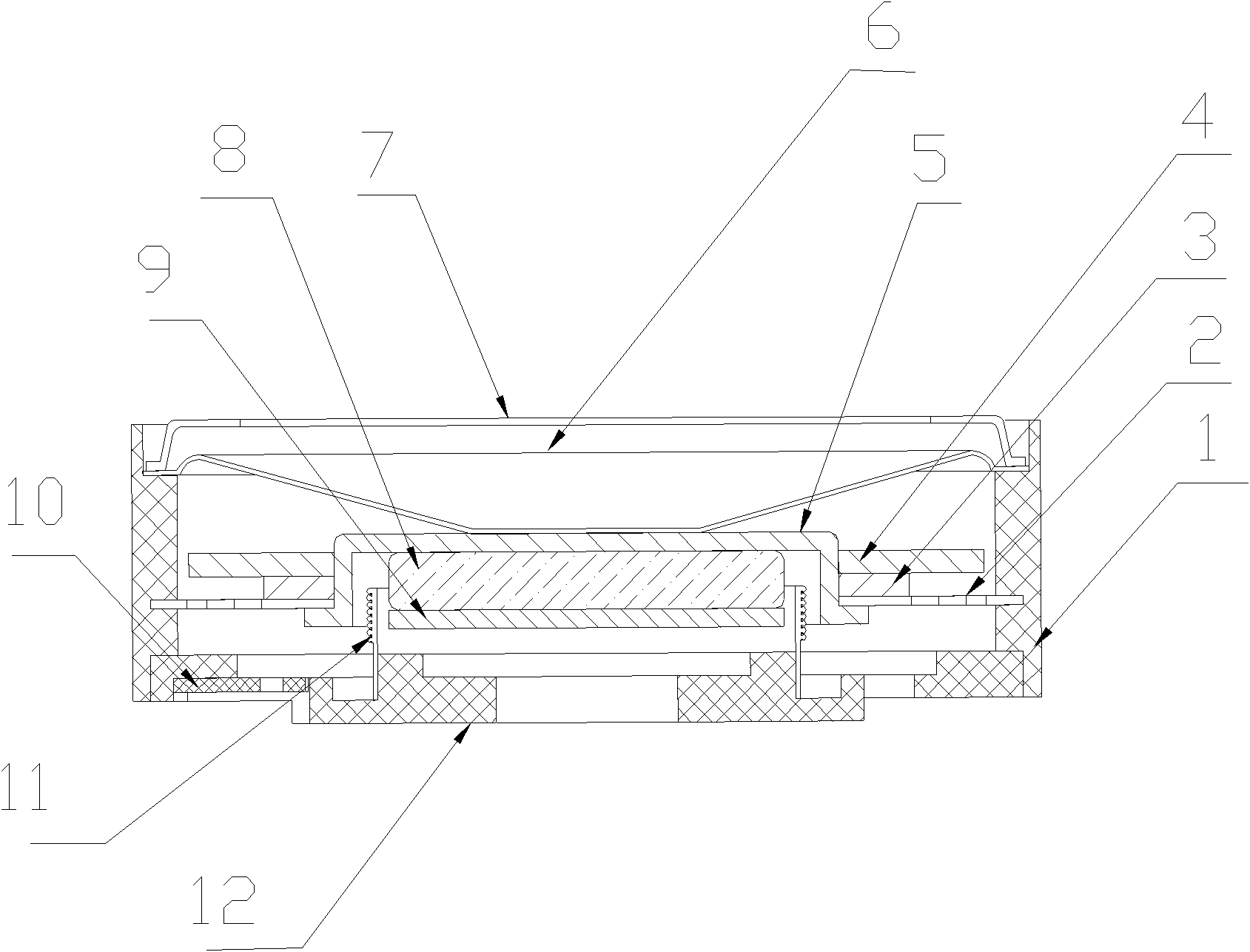

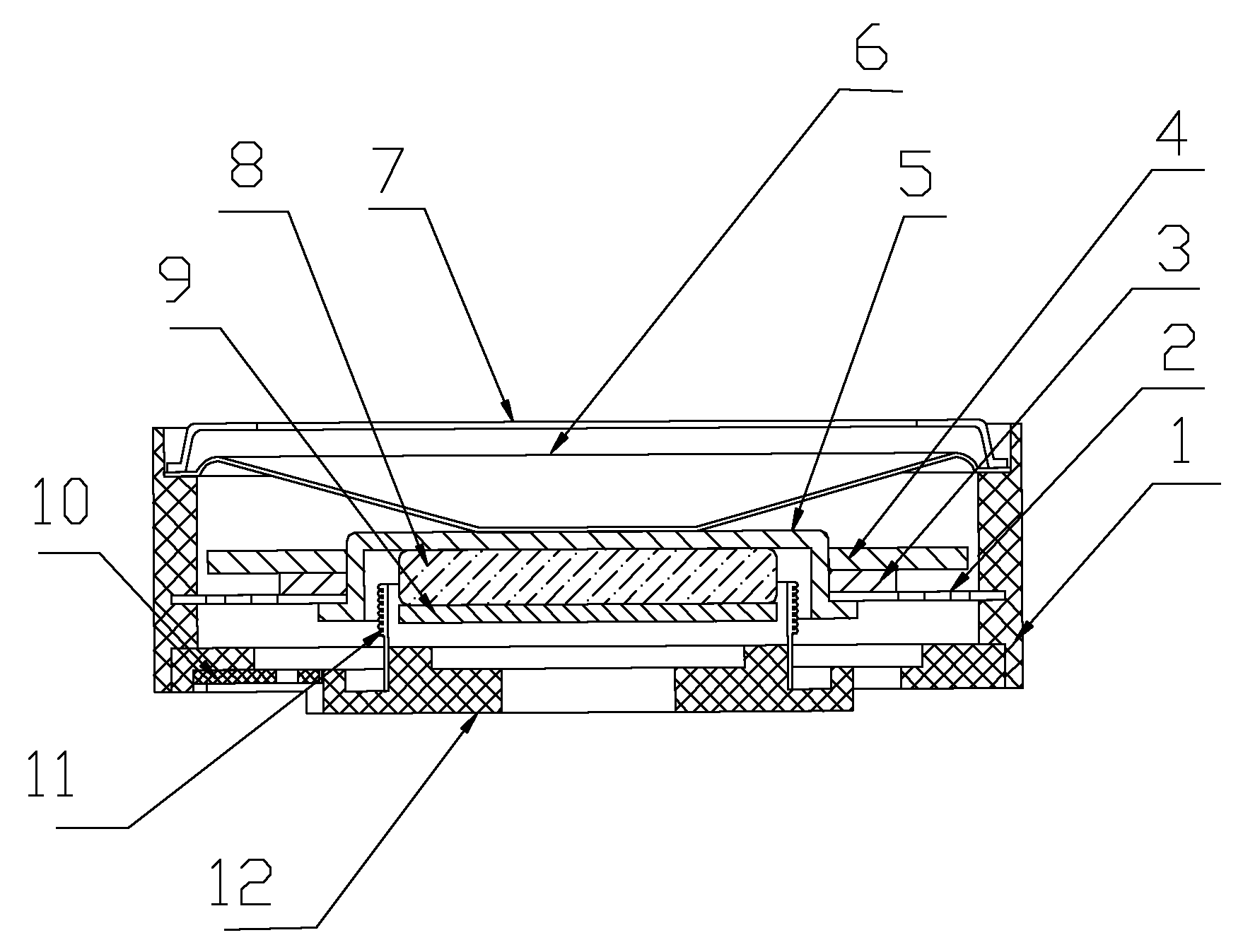

[0013] Such as figure 1 As shown, the moving iron-type low-frequency sound generator described in this embodiment includes a basin frame 1, a supporting piece 2, a spacer 3, a mass piece 4, a magnetic cup 5, a sound film 6, a front cover 7, a magnet 8, The splint 9, the printed board 10, the voice coil 11 and the back cover 12, the magnetic cup 5, the magnetic steel 8 and the splint 9 constitute a constant magnetic circuit, and the constant magnetic circuit and the supporting piece 2 constitute a vibrating magnetic circuit system. In this embodiment, the magnetic cup 5. The magnetic steel 8 and the splint 9 are glued together to form a constant magnetic circuit system; the support piece 2 adopts an insert structure and is integrally formed by injection molding with the basin frame 1. The support piece 2 is an elastic support piece, and the gasket 3 is arranged in Between the mass piece 4 and the supporting piece 2, the mass piece 4 is separated from the supporting piece 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com