Grease for high-speed bearing

A high-speed bearing and grease technology, applied in shafts and bearings, bearing components, lubricating compositions, etc., can solve problems such as viscosity reduction, inability to form lubricating oil film, difficult performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 12

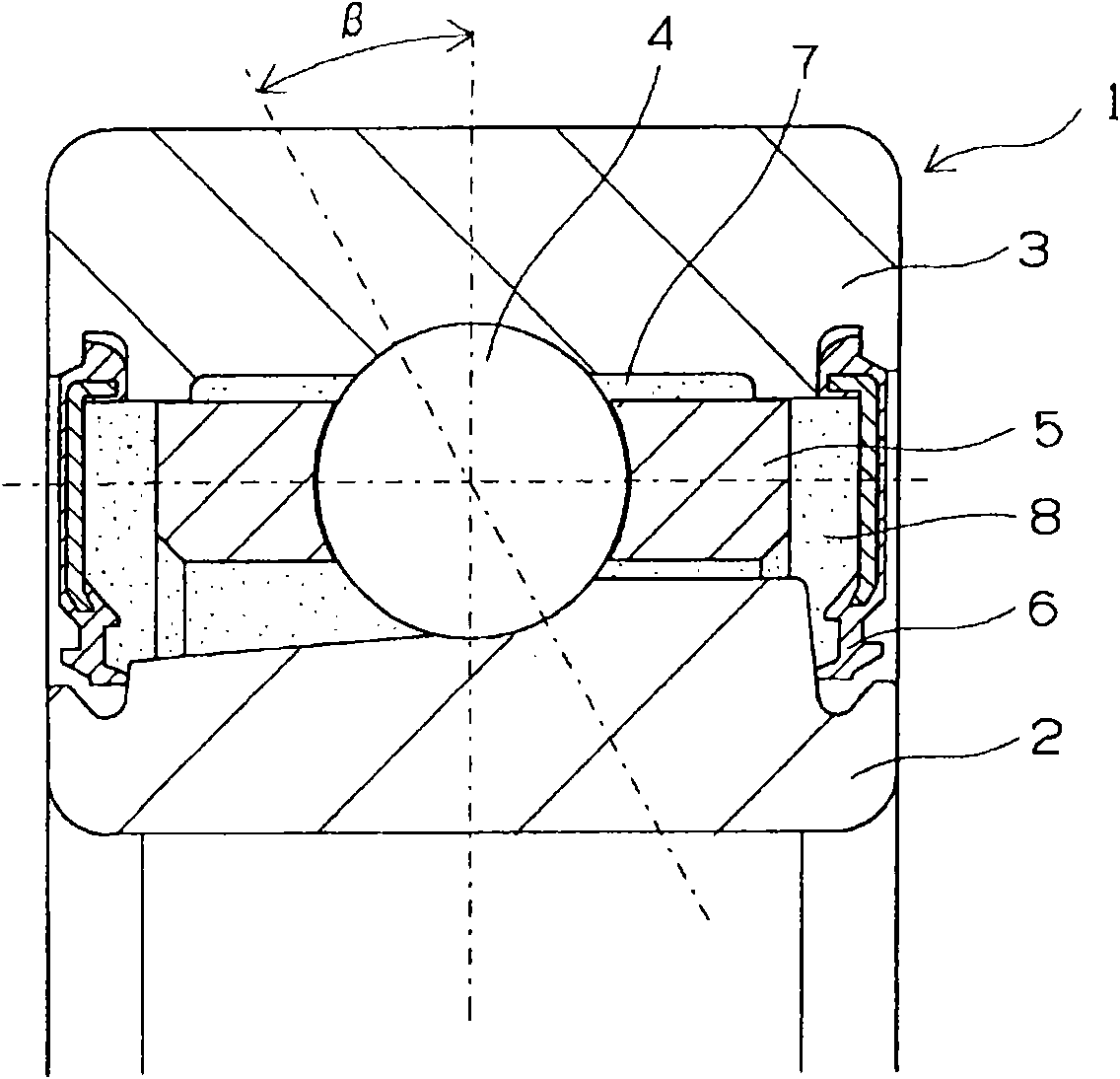

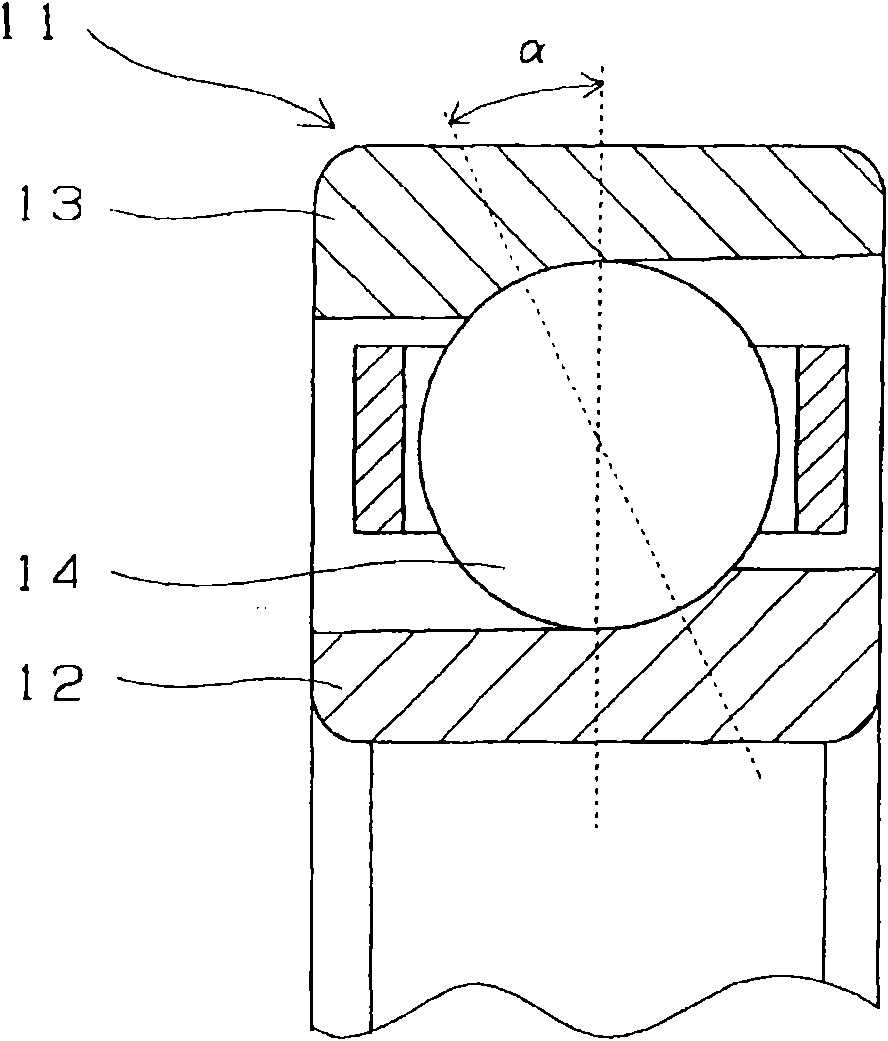

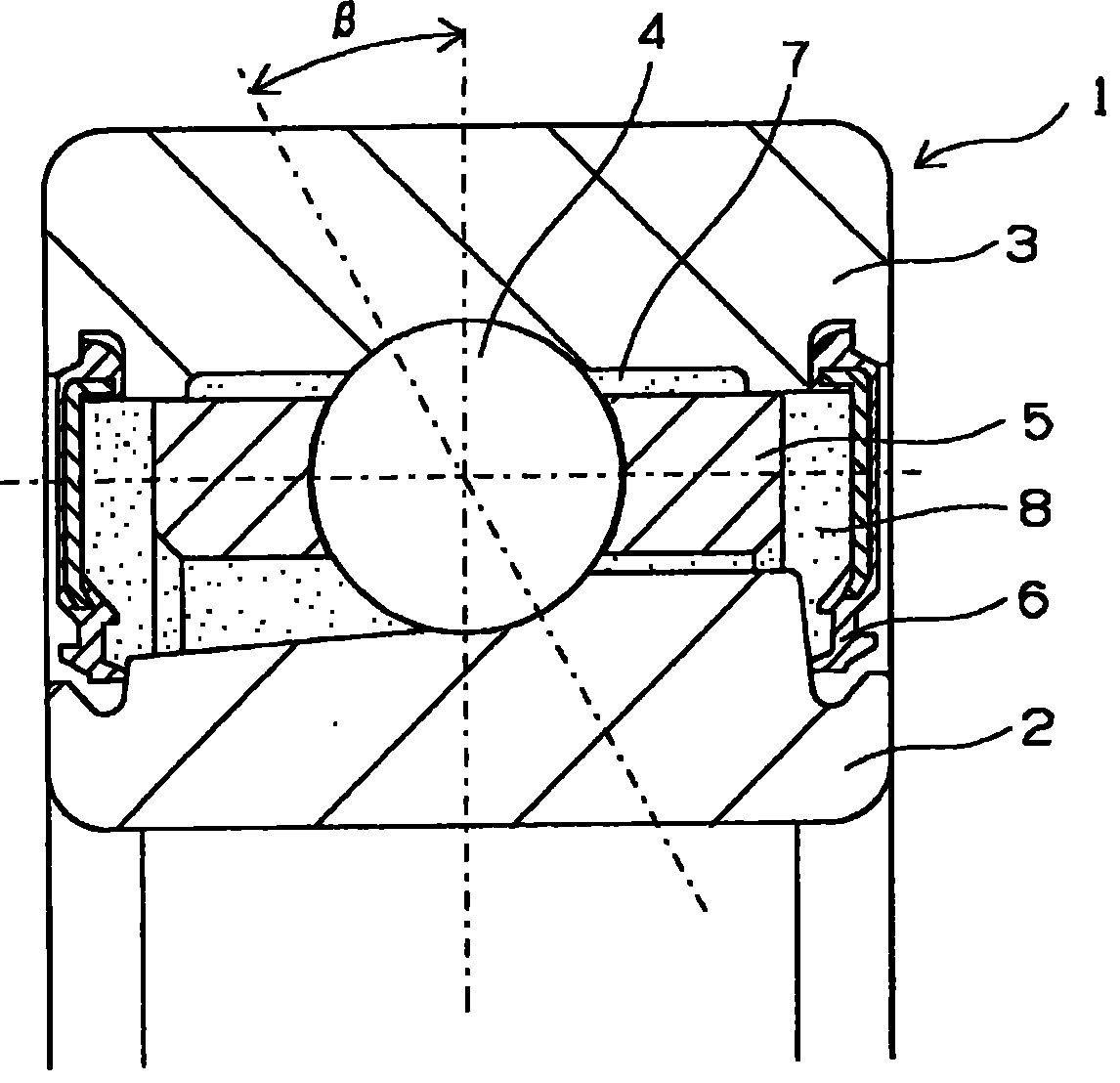

[0088]The above-mentioned urea grease and non-urea grease were mixed in the proportions shown in Table 2 to obtain grease samples. In addition, in Example 11, zinc dithiophosphate and molybdenum dithiocarbonate were each added in 2 wt % with respect to 100 wt % of the mixed grease of the above-mentioned urea grease and non-urea grease. The obtained grease samples were subjected to the following centrifugal oil separation test and normal temperature high-speed grease test using deep groove ball bearings (6204), and the centrifugal separation oil degree and grease life time were measured. In Example 1, Example 4, Example 6, Example 9, Example 11 and Example 12, the following angular contact ball bearings were used to carry out the normal temperature and high speed grease test. These measurement results are shown in Table 2 together.

[0089]

[0090] Using a centrifugal separator, put 50 g of grease into a centrifugal separation tube, and then apply the centrifugal separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com