Bowed roll block fast replacing device for rolling mill

A kind of bending block and fast technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the difficulty of maintenance and disassembly of the bending block, the narrow operation space of the bending block, and the labor intensity of workers. and other problems to achieve the effect of improving work efficiency, increasing effective travel, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

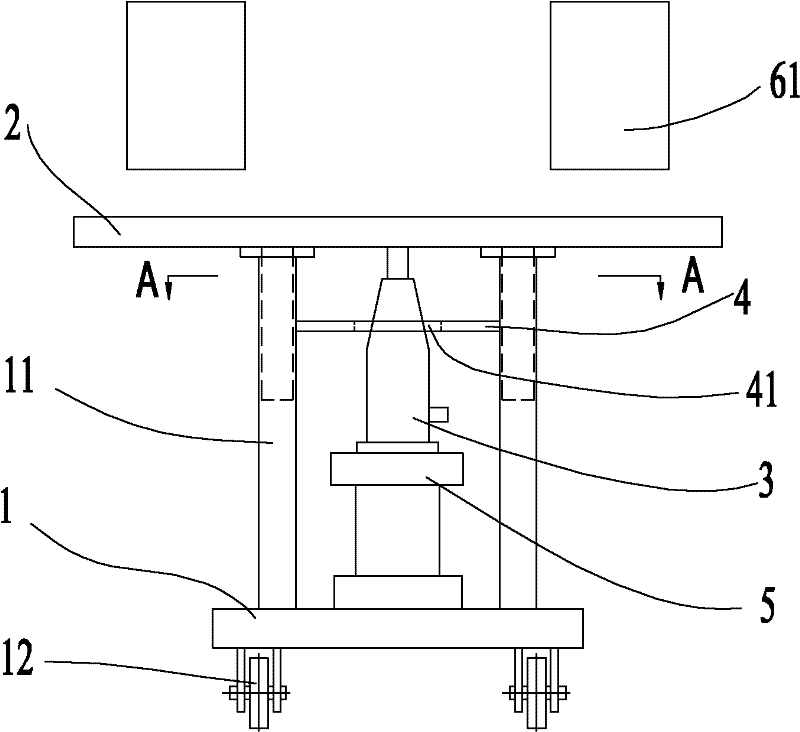

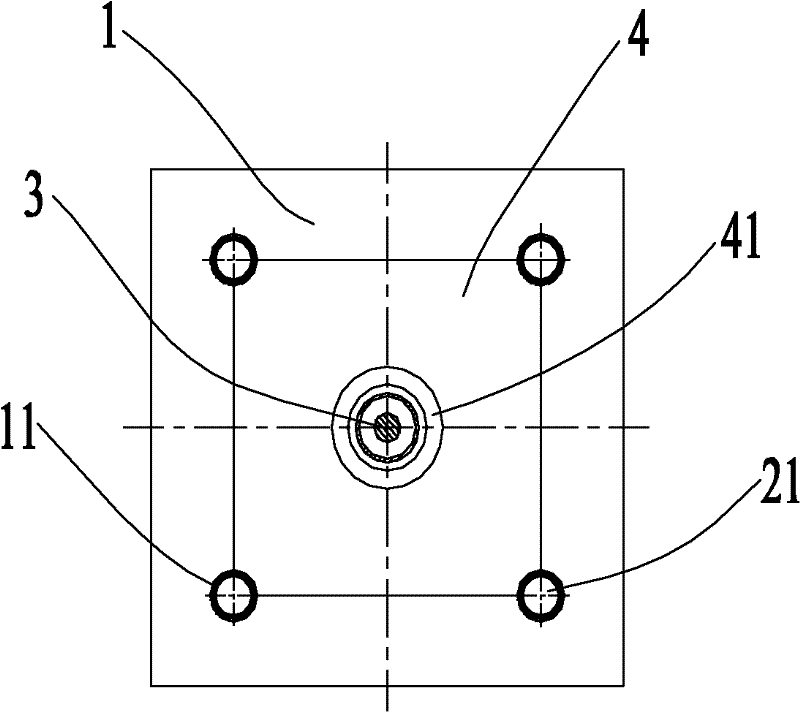

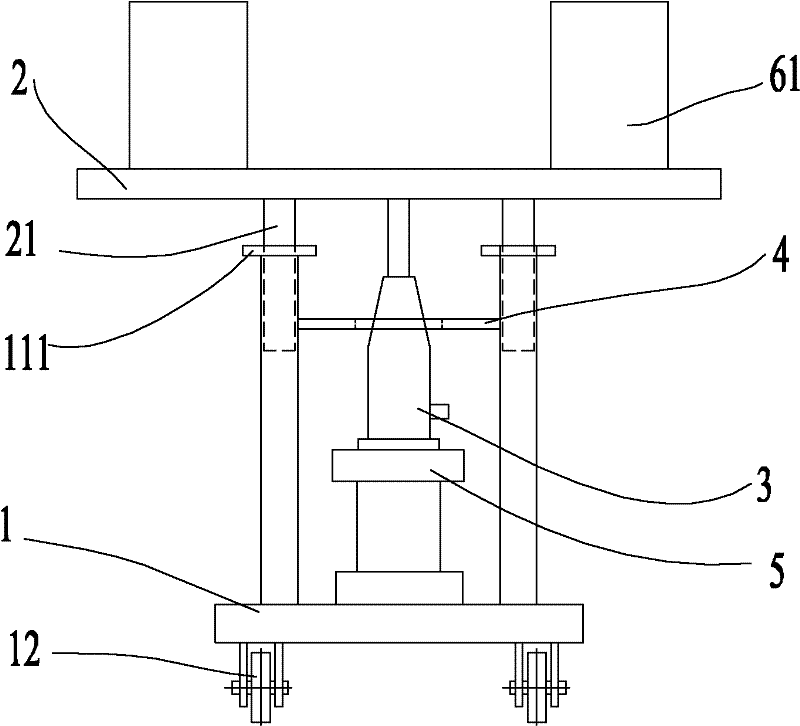

[0038] figure 1 It is a structural schematic diagram of the rolling mill bending block quick replacement device of the present invention; figure 2 is along figure 1 A schematic cross-sectional view of line A-A in the center; image 3 It is a schematic diagram of the structure when the lifting platform in the rolling mill bending block quick replacement device of the present invention is lifted.

[0039] As shown in the figure, the roll bending block quick replacement device of the present invention includes: a roll bending block replacement trolley 1, a lifting platform 2 arranged on the upper part of the bending block replacement trolley 1, and the lifting platform 2 can be moved relative to the The bending block replacement trolley 1 moves up and down, and the jack 3 arranged between the bending block replacement trolley 1 and the lifting platform 2 can control the lifting or lowering of the lifting platform 2 through the jack 3 .

[0040] In one embodiment of the presen...

Embodiment approach 2

[0051] Figure 5 It is a structural schematic diagram of another embodiment of the rolling mill bending block quick replacement device of the present invention; Image 6 It is a structural schematic diagram of the lifting platform in another embodiment of the rolling mill bending block quick replacement device of the present invention; Figure 7 is along Image 6 The cross-sectional schematic diagram of the B-B line in the middle. In this embodiment, other structures are the same as Embodiment 1 except for the lifting structure, and the same structures use the same reference numerals.

[0052] As shown in the figure, there are two guide columns 13 oppositely arranged on the roller bending block replacement trolley 1, and guide rails 14 are respectively provided on the corresponding surfaces of the two guide columns 13, and the top of the guide columns 13 is provided with a support Section 111. The lower part of the lifting platform 2 is provided with a sliding block 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com