Quick-cooling casting sand storage cabinet

A sand storage and cold mold technology, applied in the field of foundry sand treatment equipment, can solve the problems of foundry sand uniformity and water content, large equipment volume and floor area, large sand storage in the sand treatment process, etc., to improve operation Performance and service life, reduced volume and footprint, extended thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A self-adaptive superheated steam saturator of the present invention will be described in further detail below in conjunction with the accompanying drawings.

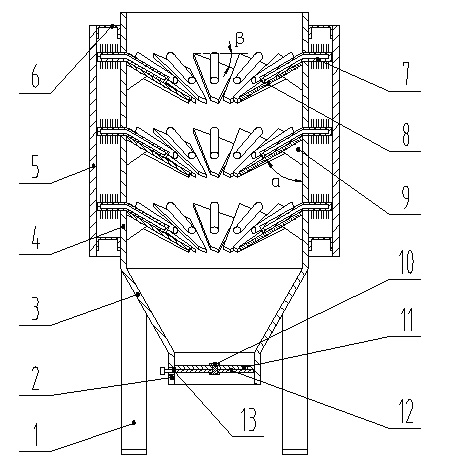

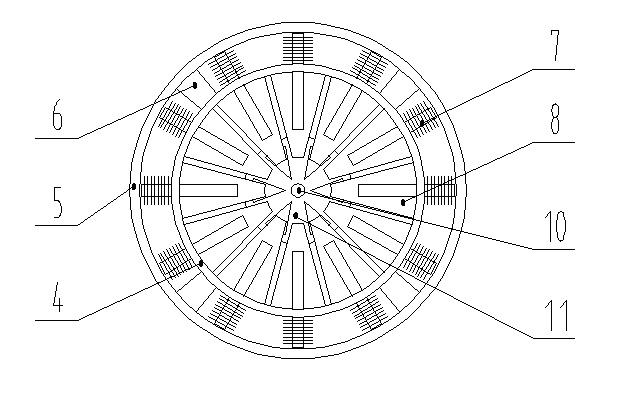

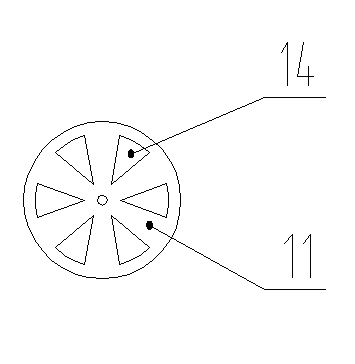

[0021] A fast-cooling casting sand storage cabinet, which consists of a support 1, a sand outlet 2, a tapered cylinder 3, an inner cylinder 4, an outer cylinder 5, an ear hook 6, a heat pipe 7, a buffer plate 8 and a rib plate 9 composition. The inner cylinder 4 is a cylinder placed vertically, the lower part of which is connected to the sand outlet 2 by a conical cylinder 3 and welded on the support 1; the sand outlet 2 is a cylindrical structure, its There is a sand-discharging mechanism inside; the sand-discharging mechanism is composed of a dynamic valve plate 12 and a static valve plate 11 with the same fan-shaped window 14. 11 is welded with the cylinder wall of the sand outlet 2, the movable valve plate 12 is located under the static valve plate 11, and the movable valve plate 12 is equipped with a handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com