A textile machine with drying function

A textile machine and functional technology, applied in the field of textile machines with drying function, can solve the problems of moldy textile fabrics, insufficient dryness of textile threads, and inability to maintain dryness, etc., and achieve the effect of fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

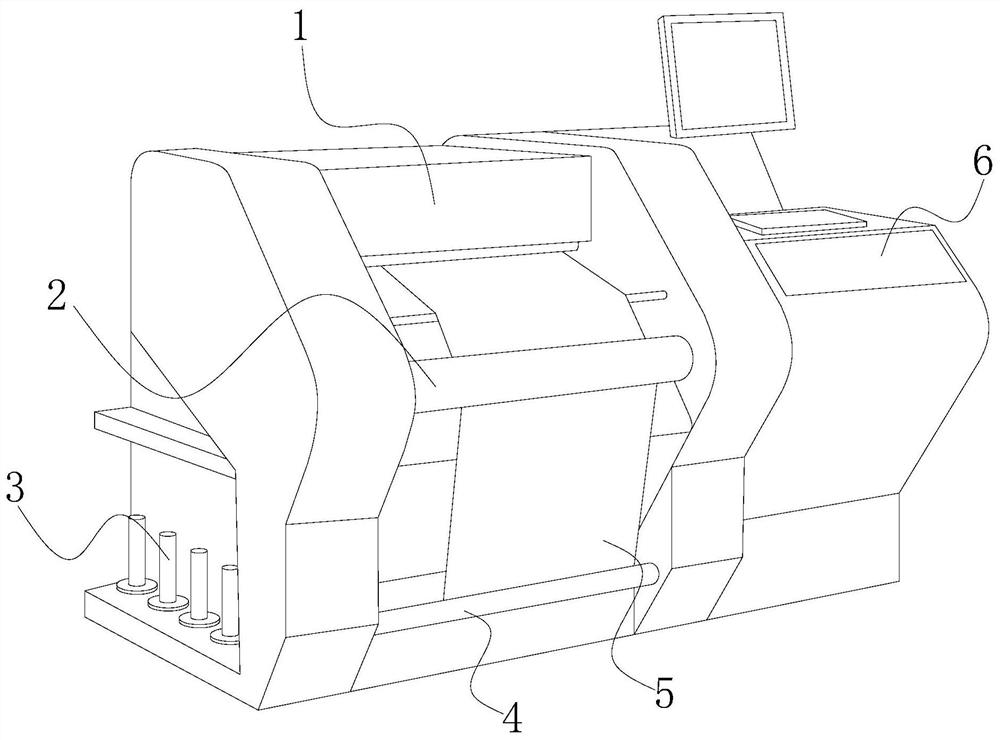

[0027] see Figure 1-Figure 5 , the present invention provides a kind of textile machine with drying function, its structure comprises textile chamber 1, drying cylinder 2, bobbin 3, guide roller 4, textile cloth 5, shell 6, and described textile chamber 1 is provided with textile Cloth 5, the textile cloth 5 is connected with the drying cylinder 2, the drying cylinder 2 is connected with the guide roller 4 through the textile cloth 5, and the textile chamber 1 is installed in the housing 6;

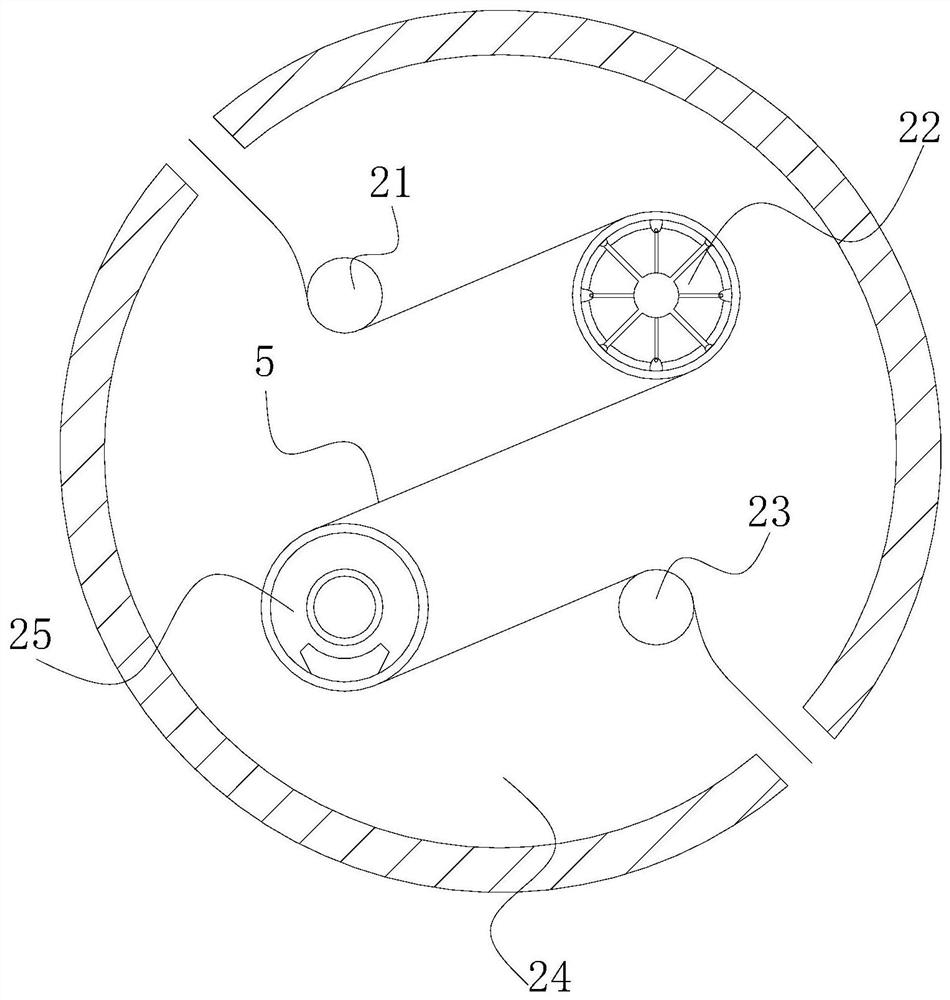

[0028] The drying drum 2 is composed of an inlet shaft 21, a drying roller 22, an outlet shaft 23, a barrel chamber 24, and a cooling roller 25. The inlet shaft 21 and the outlet shaft 23 are on the same axis, and the drying roller 22 and The cooling roller 25 is on the same axis, the diameter of the introduction shaft 21 is substantially perpendicular to the diameter of the drying roller 22, and the textile cloth 5 is connected with the drying roller 22 through the introduction shaft 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com