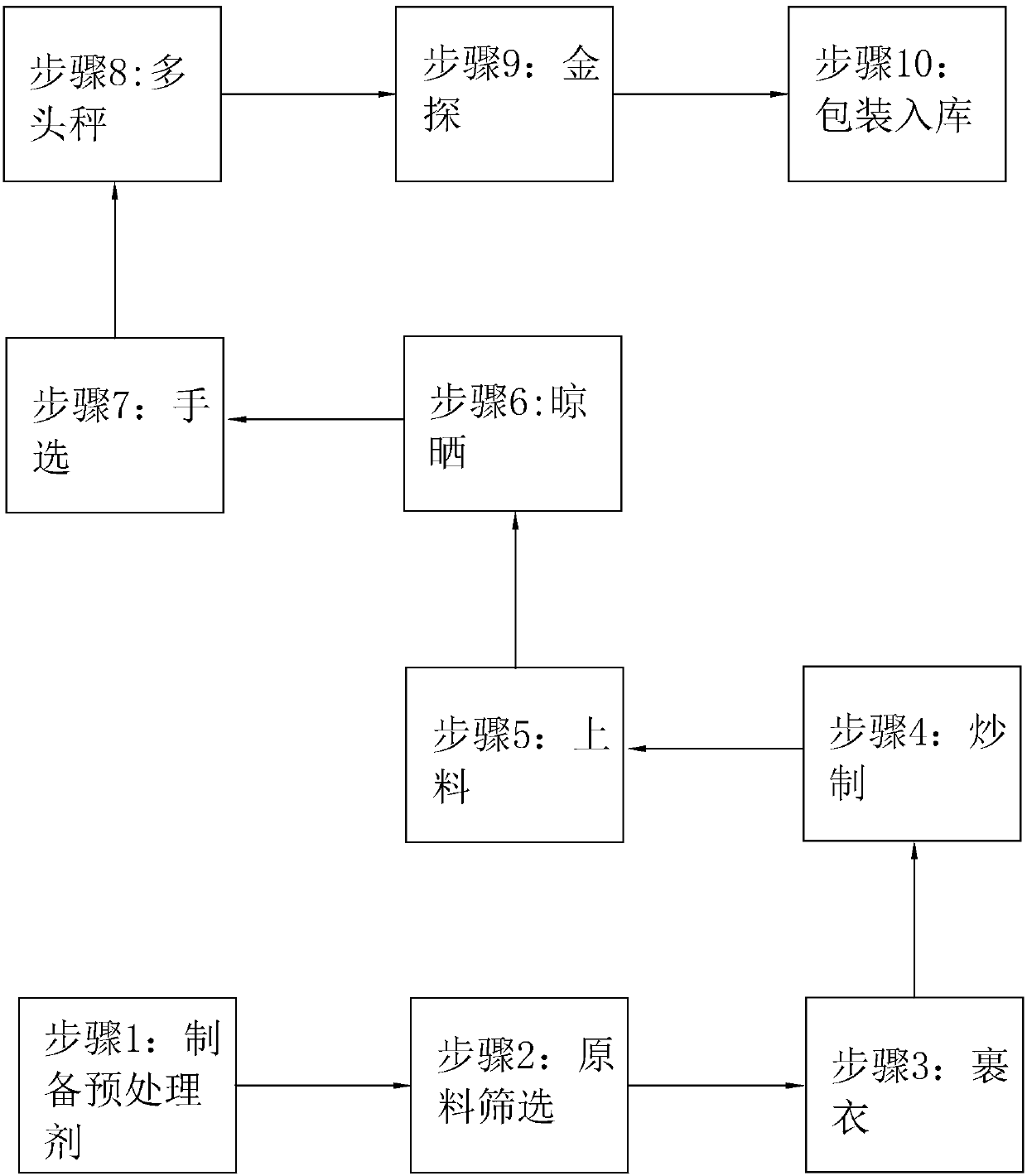

Multi-flavor peanut processing technology

A processing technology, peanut technology, applied in the direction of food ingredients as taste improver, food science, food ingredients as taste improver, etc. Loss, reduce dry mouth, enhance taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

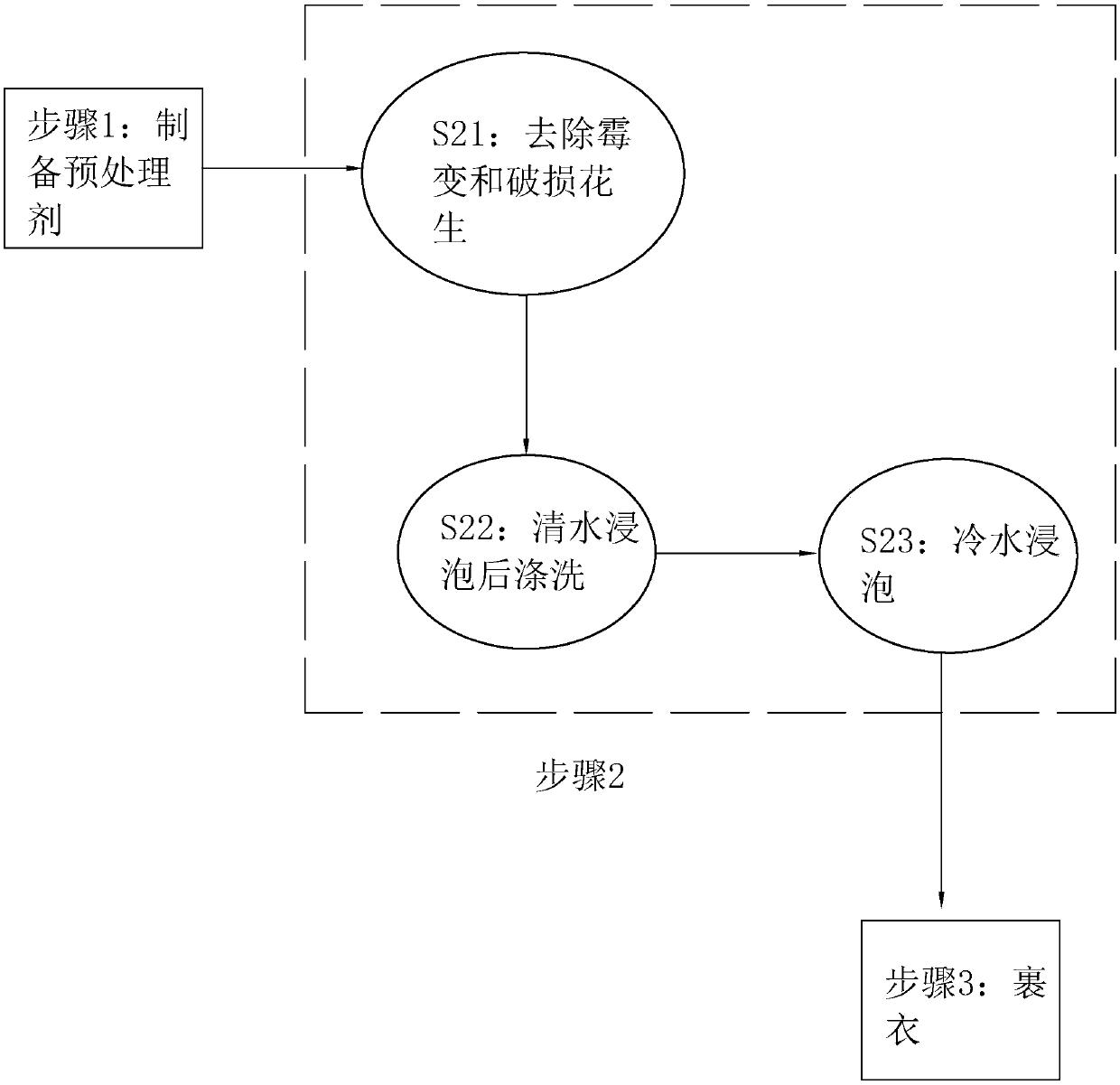

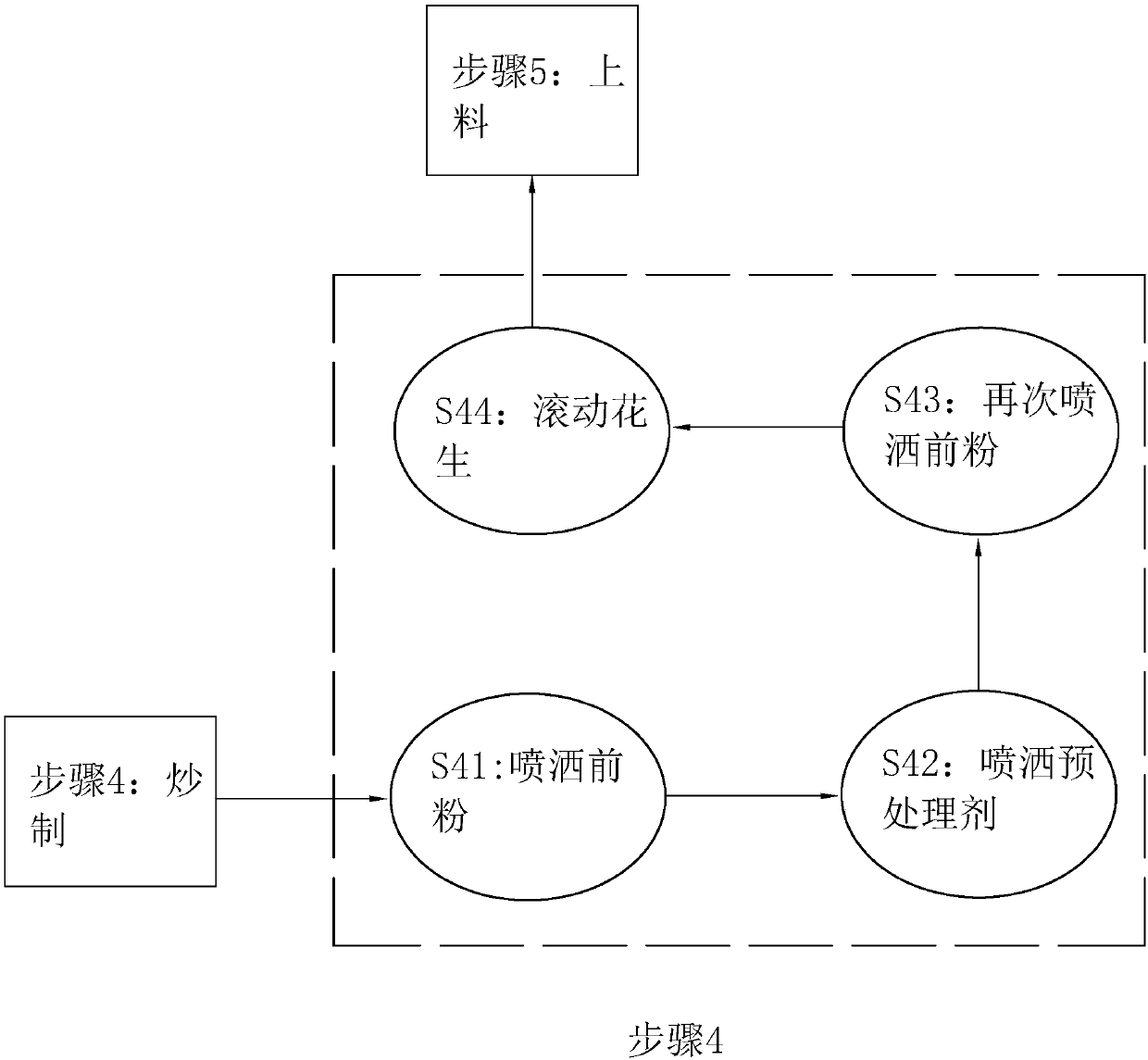

Method used

Image

Examples

Embodiment 1

[0044] Take a clean container A and add hot water, gum arabic, sorbitol, glucose, edible salt and xanthan gum to it, wherein the hot water accounts for 61% of the total weight, the hot water of sorbitol accounts for 10% of the total weight, and the glucose 15% of the total weight, edible salt 2% of the total weight, and xanthan gum 10% of the total weight.

[0045] Take a clean container B, mix the gum arabic and xanthan gum and stir evenly, then take a clean container A, pour hot water into it, and then pour sorbitol, glucose and edible salt on the clean container A. The process continues to stir; then pour the mixed gum arabic and xanthan gum from the clean container B into the clean container A. This process continues to stir until the preparation of the pre-treatment agent is completed, and the pre-treatment agent is continuously treated. Stir until blended.

[0046]Take a clean container C, add salt powder, wheat flour, puffed powder, chili powder, deformed starch and gl...

Embodiment 2

[0050] Take a clean container A and add hot water, gum arabic, sorbitol, glucose, edible salt and xanthan gum to it, wherein the hot water accounts for 63% of the total weight, the hot water of sorbitol accounts for 12% of the total weight, and the glucose 17% of the total weight, edible salt 4% of the total weight, and xanthan gum 4% of the total weight.

[0051] Take a clean container B, mix the gum arabic and xanthan gum and stir evenly, then take a clean container A, pour hot water into it, and then pour sorbitol, glucose and edible salt on the clean container A. The process continues to stir; then pour the mixed gum arabic and xanthan gum from the clean container B into the clean container A. This process continues to stir until the preparation of the pre-treatment agent is completed, and the pre-treatment agent is continuously treated. Stir until blended.

[0052] Take a clean container C, add salt powder, wheat flour, puffed powder, chili powder, deformed starch and gl...

Embodiment 3

[0056] Take a clean container A and add hot water, gum arabic, sorbitol, glucose, edible salt and xanthan gum to it, wherein the hot water accounts for 62% of the total weight, the hot water of sorbitol accounts for 11% of the total weight, and the glucose 16% of the total weight, edible salt 3% of the total weight, and xanthan gum 8% of the total weight.

[0057] Take a clean container B, mix the gum arabic and xanthan gum and stir evenly, then take a clean container A, pour hot water into it, and then pour sorbitol, glucose and edible salt on the clean container A. The process continues to stir; then pour the mixed gum arabic and xanthan gum from the clean container B into the clean container A. This process continues to stir until the preparation of the pre-treatment agent is completed, and the pre-treatment agent is continuously treated. Stir until blended.

[0058] Take a clean container C, add salt powder, wheat flour, puffed powder, chili powder, deformed starch and gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com