Precise positioning fixture for numerical control machining of thin-wall blade

A precise positioning and blade technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of easy vibration and the inability to accurately control the blade clamping force, reduce processing deformation, improve CNC machining efficiency, The effect of improving machining accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

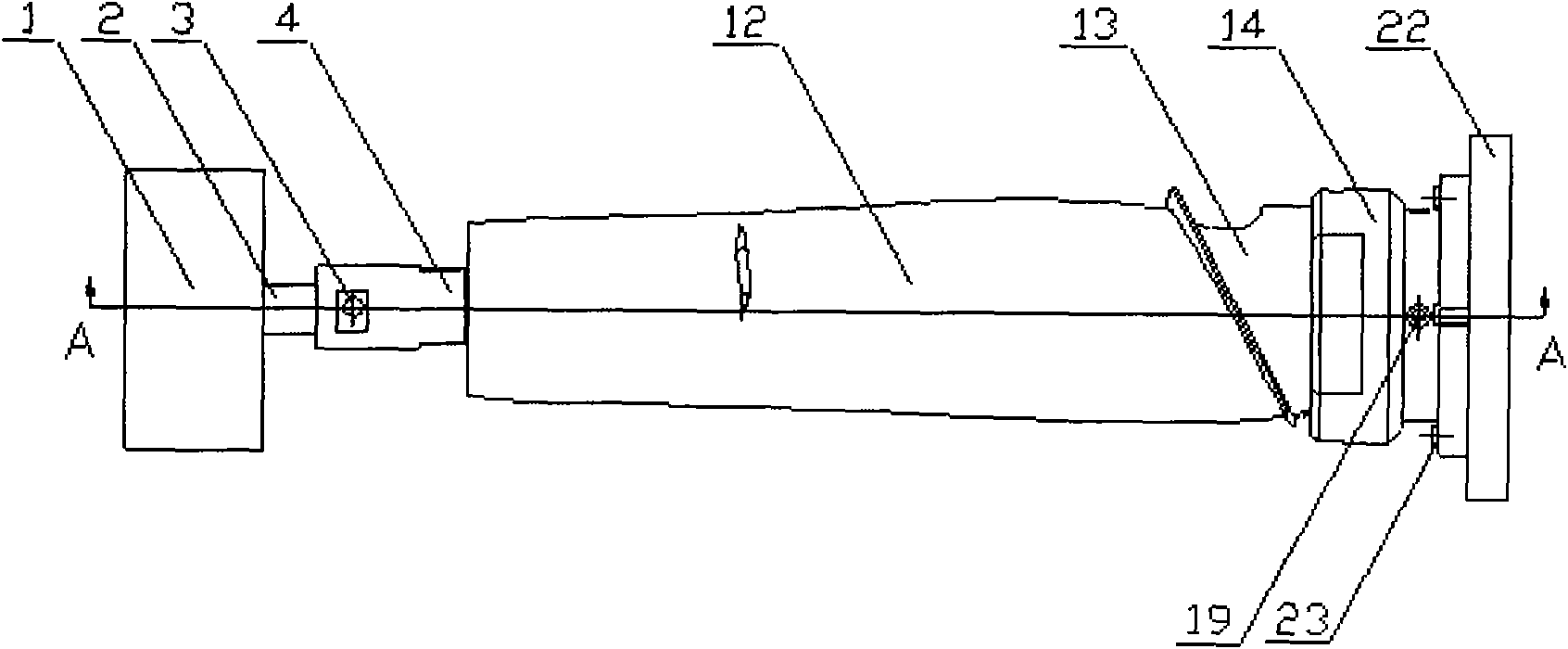

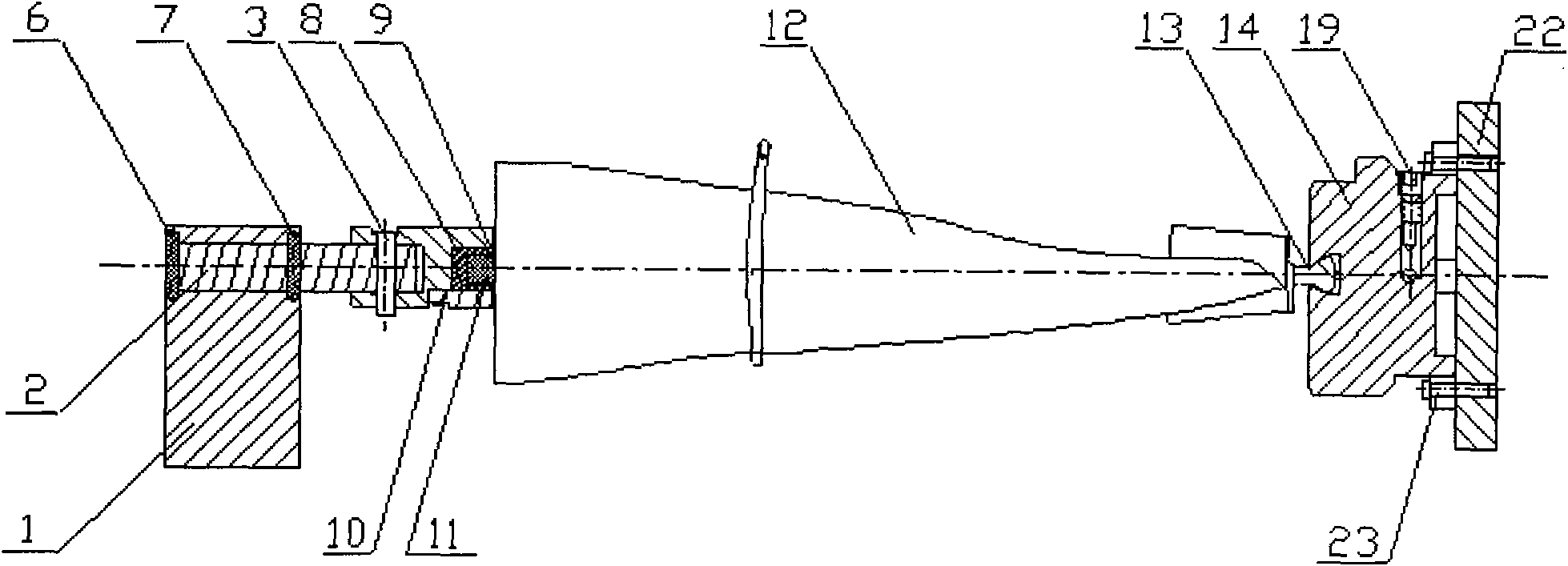

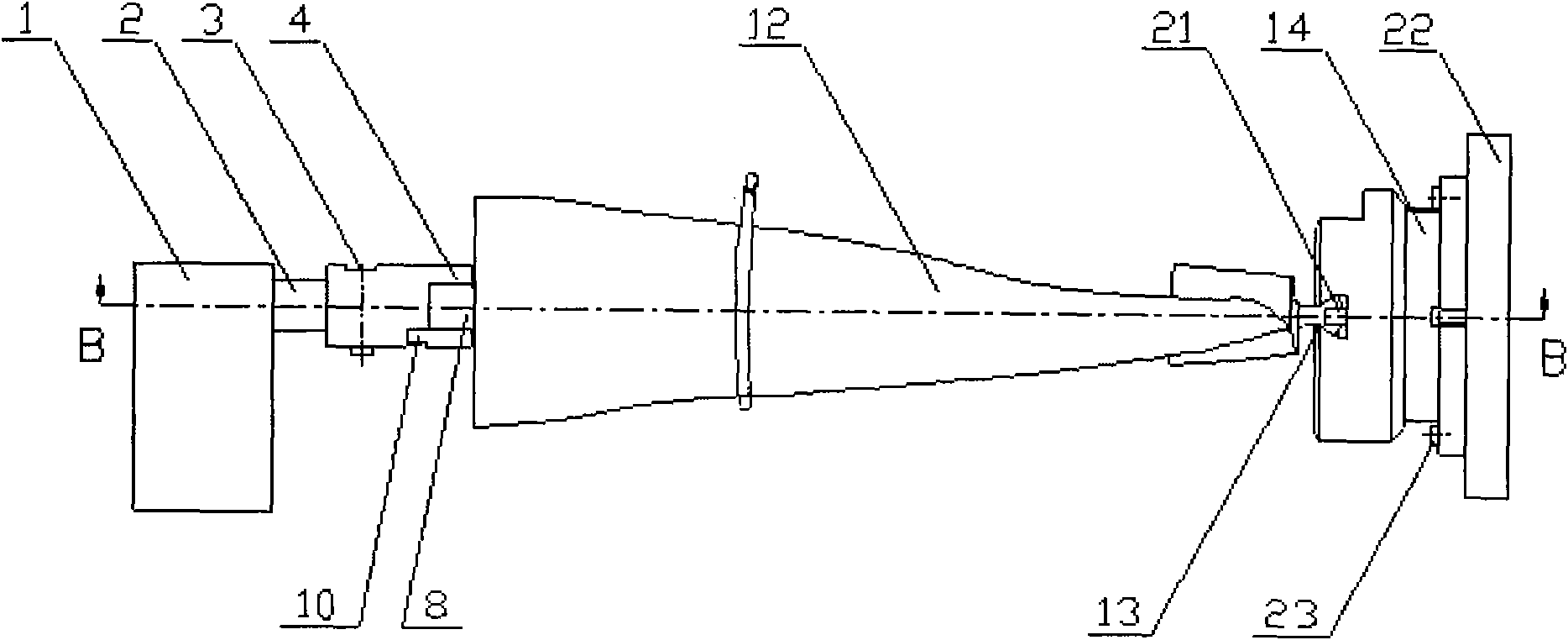

[0022] Such as Figures 1 to 5 As shown, the precision positioning fixture for CNC machining of thin-walled blades includes a clamp body, and the clamp body is composed of a tenon positioning plate 14 for clamping the tenon root 13 of the blade and a positioning mandrel 4 for clamping the tip of the blade 12 , the tenon positioning plate 14 is installed on the rotary table 22, and the tenon positioning plate 14 is provided with a blade tenon root installation groove 25, an axial oil passage 15 of the tenon positioning plate and a radial oil passage 18 of the tenon positioning plate, and the blade One end of the tenon root installation groove 25 is provided with a positioning pin 21, and the other end of the blade tenon root installation groove 25 is provided with a compression screw 24 corresponding to the blade tenon root 13, and there are two axial oil passages 15 for the tenon root positioning plate. The axial oil passages of the two mortise positioning discs are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com