Method for nitriding molten steel stably

A liquid steel, stable technology, applied in the field of liquid steel nitrogen increase in the LF refining process, can solve the problems of poor nitrogen absorption stability, long nitrogen blowing time, high smelting cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

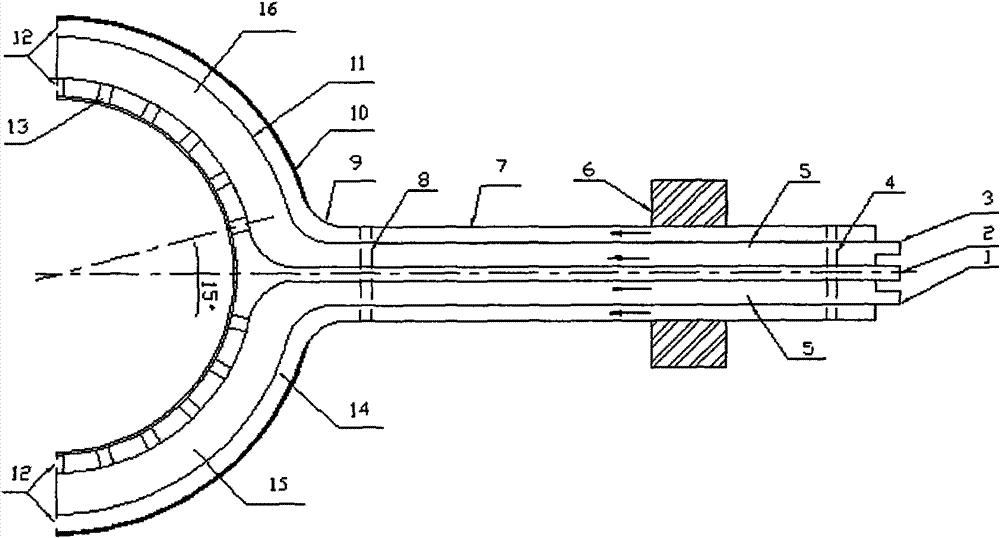

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] Implement the following technical solutions on 500kgLF:

[0017] In the process of slagging, after slagging and deoxidation is completed, a nitrogen gun is inserted at the furnace door to increase nitrogen. In order to achieve the best nitrogen increasing effect, the pressure of nitrogen injection is 0.6MPa, and the purity of nitrogen is 98.4%. The bottom blowing gas used in the nitrogen blowing process is argon, and the bottom blowing flow rate is 800NL / min. In order to ensure stable nitrogen increase, the LF ladle bottom breathable brick adopts central arrangement and single hole blowing, and the distance between the nitrogen increase gun and the steel liquid surface 60mm.

[0018] After the slag is foamed, long-arc operation is used for power supply. When the electrode submerged arc is stable, nitrogen gas is evenly blown into the arc p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com