Plate type ballastless track turnout plate and manufacture method thereof

A technology for slab ballastless track and turnout plate, which is applied in manufacturing tools, track, track maintenance, etc., can solve the problems of unsuitable size of lateral rail bearing platform, heavy maintenance workload, poor conformity, etc., and achieves easy implementation of factory management. , The effect of short production cycle and improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

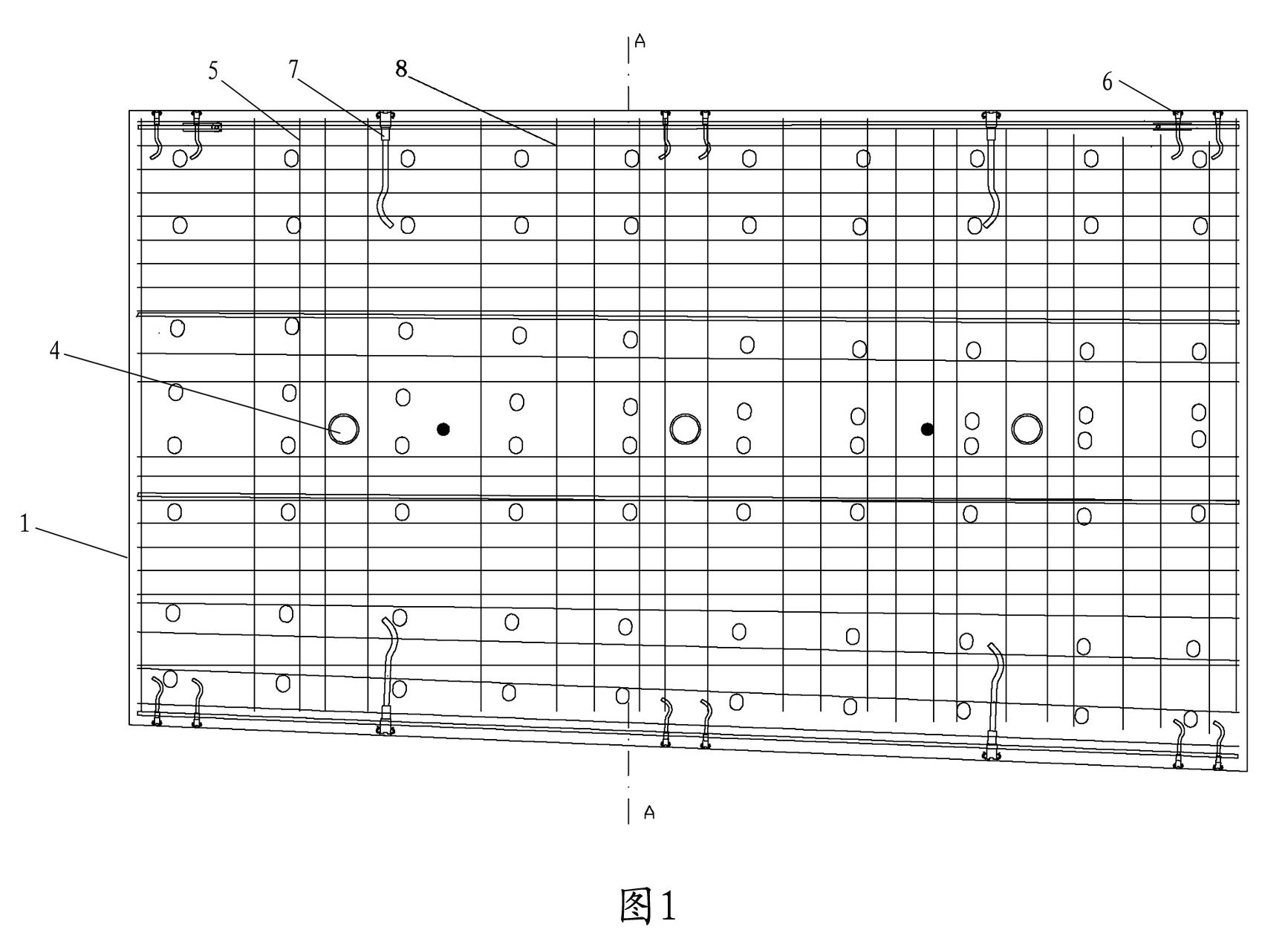

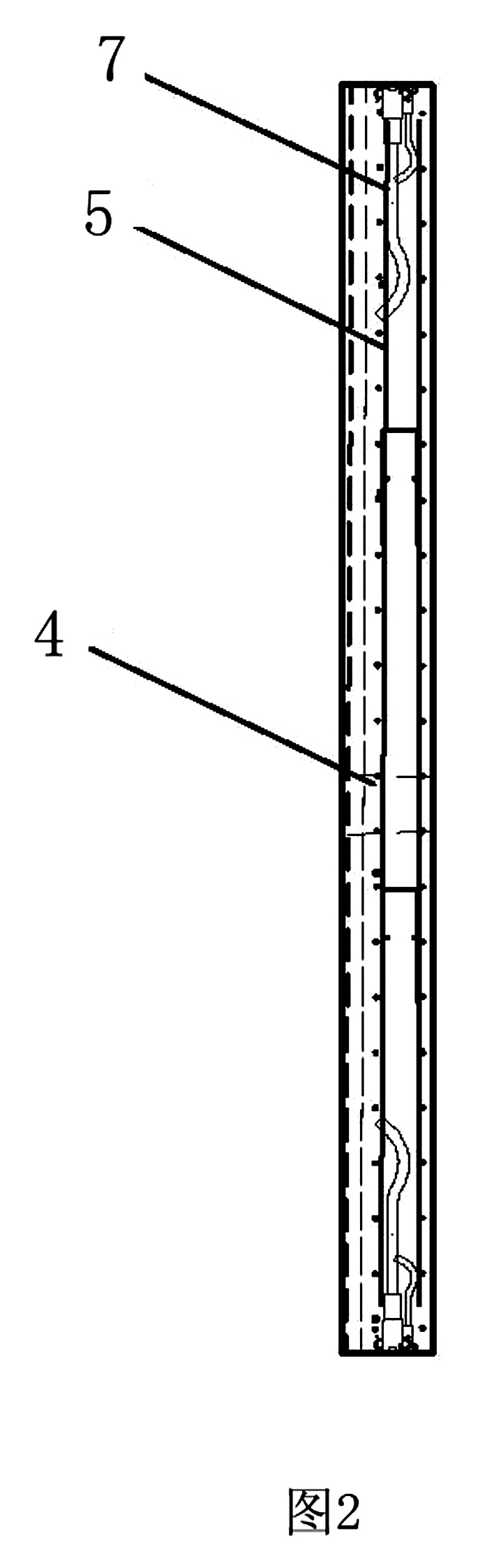

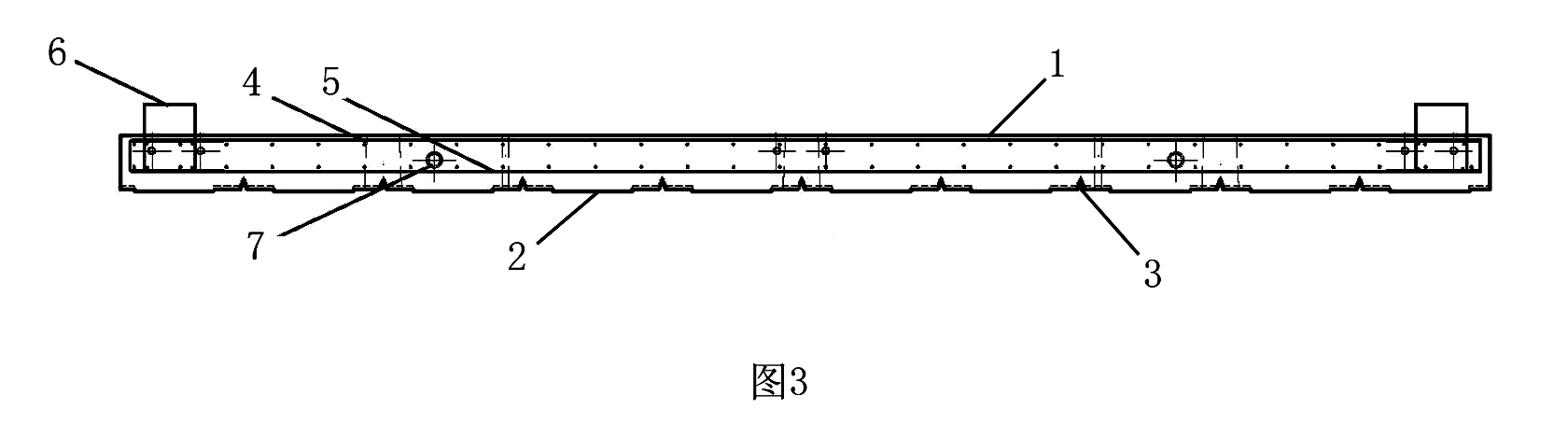

[0040] Such as figure 1 , figure 2 , image 3 As shown, the slab type ballastless track turnout plate system includes No. 18 crossing line turnout plate, No. 18 opening line turnout plate, No. 50 turnout plate, and No. 42 turnout plate. A slab type ballastless track turnout slab, the slab body 1 is a reinforced concrete structure, the edge of the slab body 1 has pre-embedded ribs 6 and pre-embedded hoisting parts 7, and the concrete is covered with a reinforcement mesh 5, the warp and weft of the reinforcement mesh 5 The intersections of steel bars are bound and connected by insulating cable ties 8. The thickness of the board body 1 is 240 mm, and a horizontal rail bearing platform 2 with a width of 300 mm and a longitudinal spacing of 600 mm is arranged on it. The surface of the rail bearing platform 2 is horizontal; The surface of the turnout plate is provided with 0.5% lateral drainage slope and transverse pre-crack 3 with a depth of 40mm, and there are positioning holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com