L-shaped mining method under open-underground mining

A mining method and open-pit mining technology, which can be used in surface mining, earthwork drilling, underground mining, etc., can solve problems such as losses, reduce labor costs, and improve the recovery rate of mineral resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

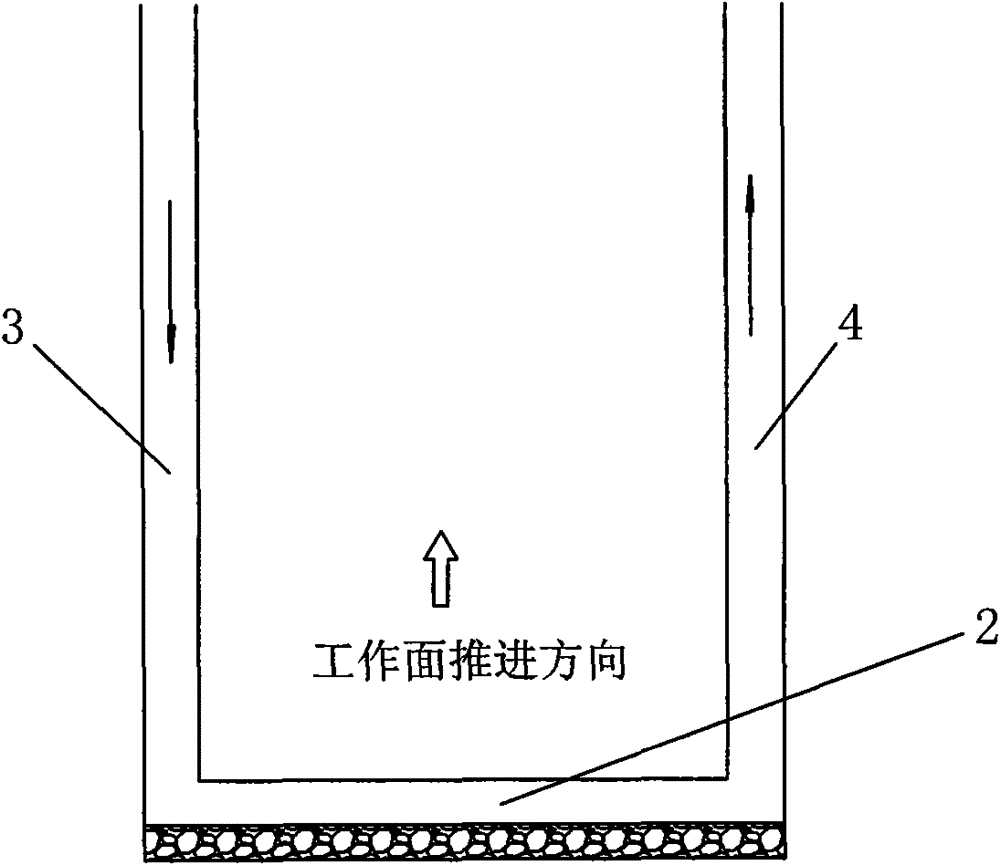

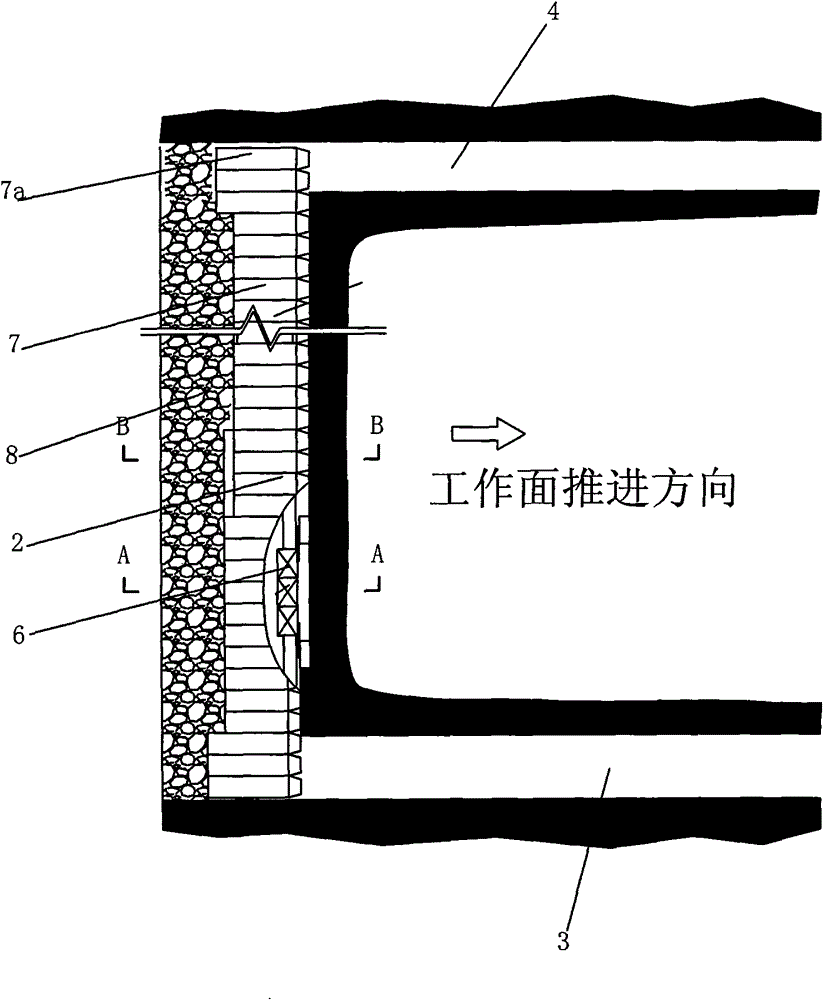

[0040] The L-shaped mining method of open well combined mining of the present invention has two important characteristics. First, change the existing mining method that forms the air intake trough, the working face and the return air trough from the excavation to the mining method that only forms the air intake trough and the stoping face; The U-shaped layout of the wind-slow trough, the working face and the return wind-slow trough is changed to the L-shaped layout of the air-inlet trough and the working face.

[0041] In addition, the L-shaped arrangement of the working face and the air inlet trough are connected with the press-in ventilation system of the mine.

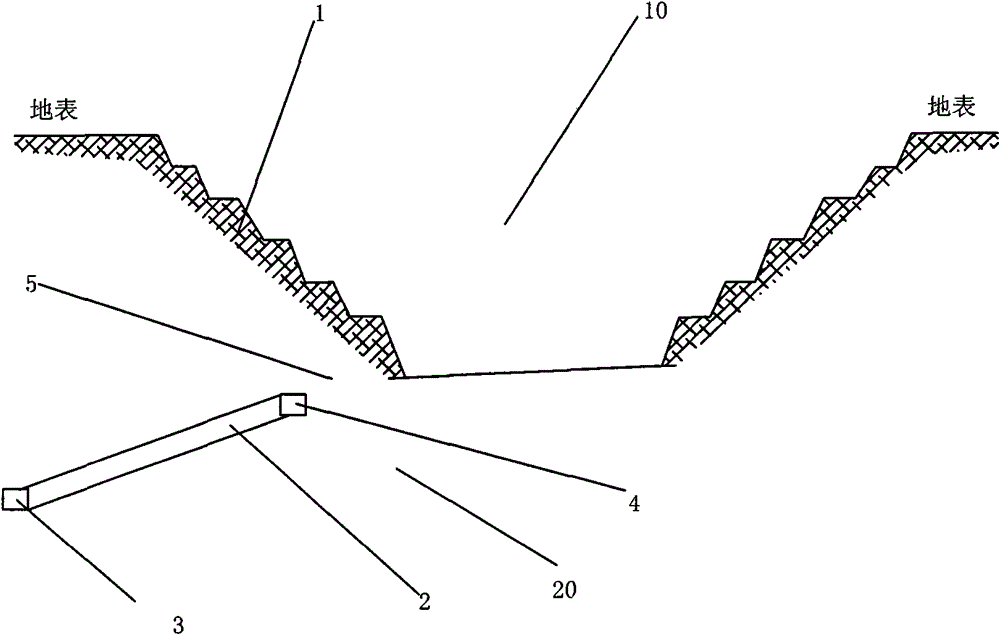

[0042] image 3 The mining method of open well combined mining of the present invention is shown. Such as image 3 As shown, the present invention first starts open-pit mining from the surface, and uses mining equipment to mine the open-pit mine. When the open-pit mining reaches the depth required for underground minin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com