Biomimetic processing method for leading edge of blade at end area

A technology for the leading edge of a blade and a treatment method, which is applied to the components of the pumping device for elastic fluid, the non-variable displacement pump, the machine/engine, etc., to achieve the effect of improving the aerodynamic performance and improving the efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

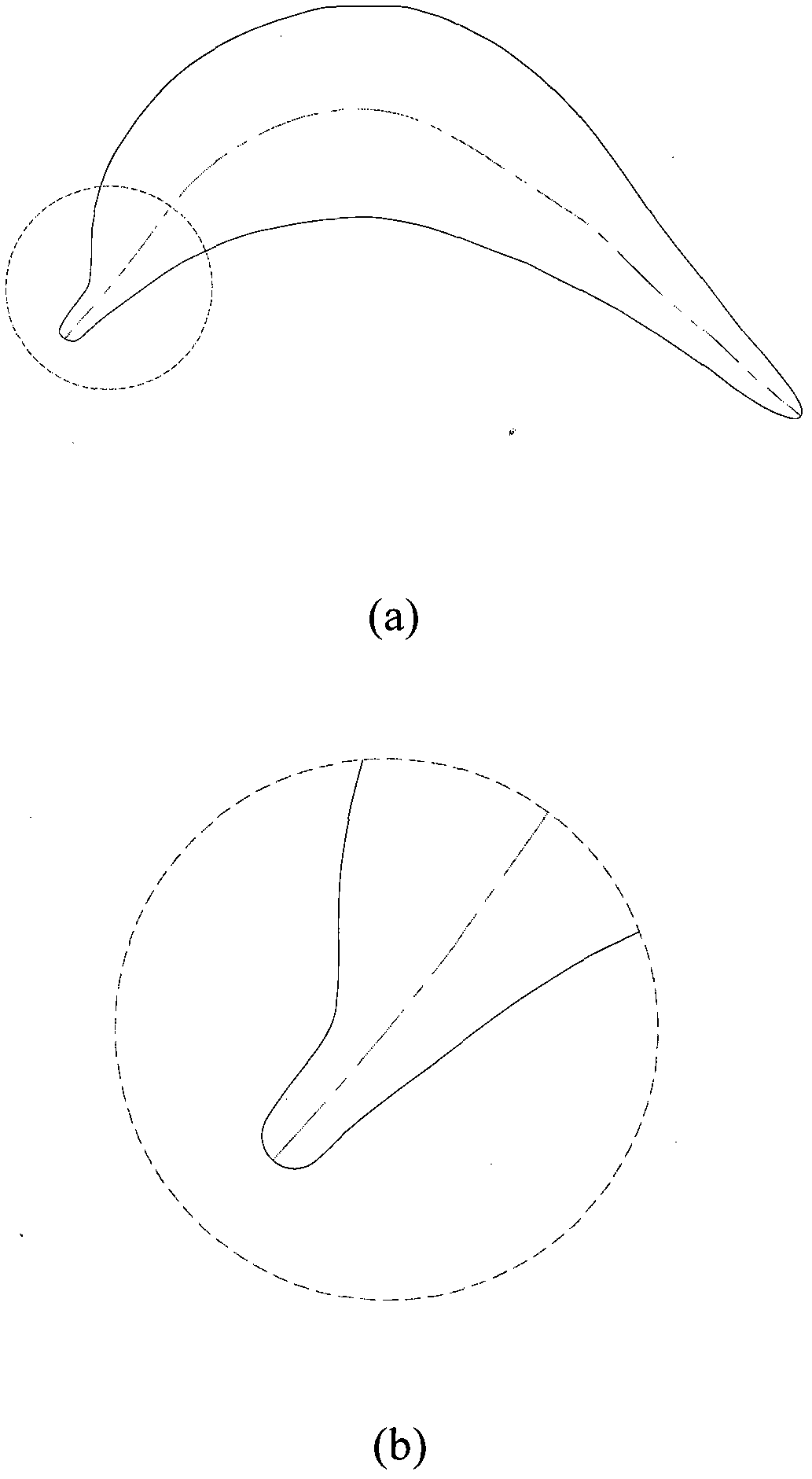

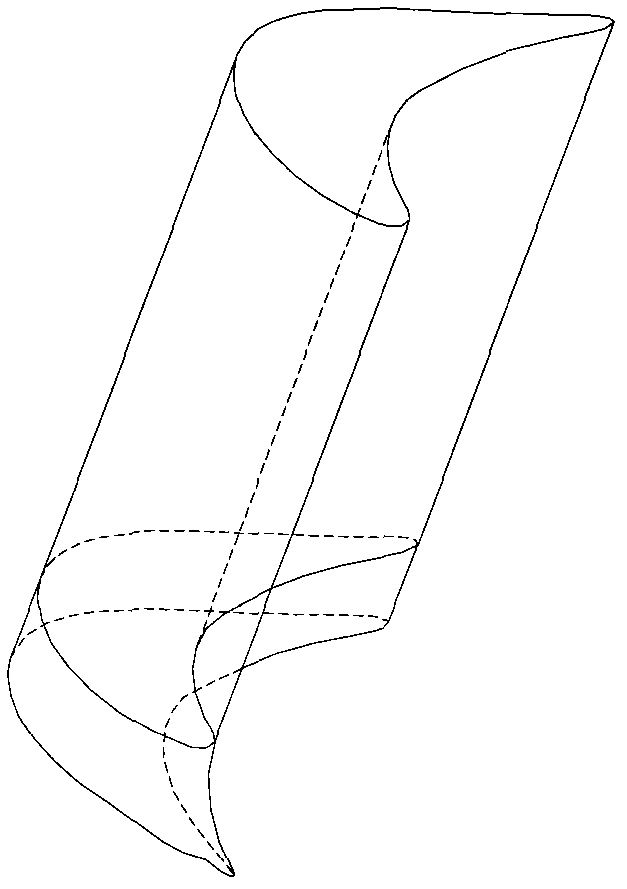

[0026] In order to better illustrate the purpose and advantages of the present invention, the content of the invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] In this embodiment, an axial flow compressor blade (NACA65 airfoil) is redesigned according to the method described in the content of the invention, and its effect is verified by numerical simulation. The relevant pneumatic parameters of this embodiment are as follows: the total inlet pressure is 103379Pa, the incoming flow Mach number is 0.2, and the outlet static pressure is 101325Pa.

[0028] The specific implementation process of this embodiment is as follows:

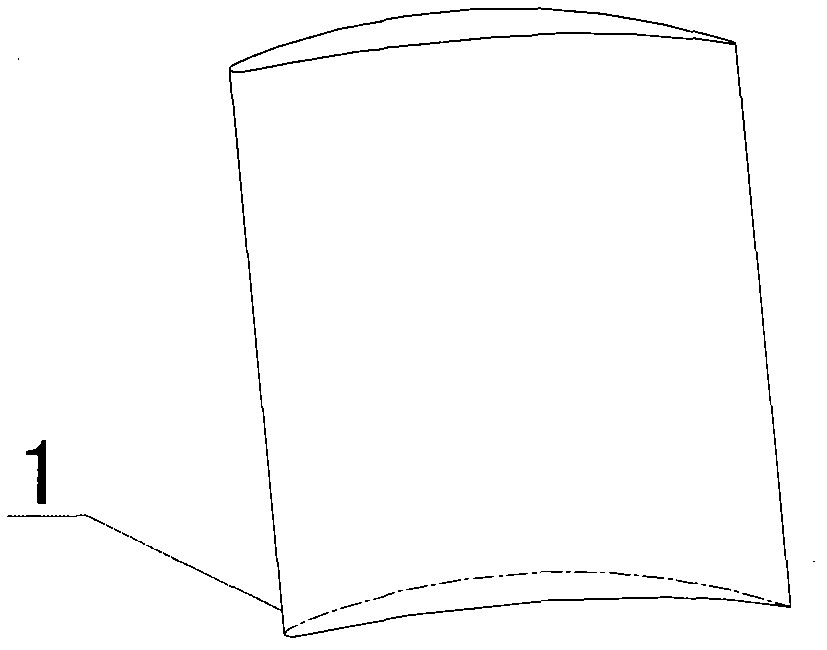

[0029] Step 1. According to the original airfoil data, the geometric parameters of the cascade and the aerodynamic parameters, the shape of the original compressor blade is given, such as figure 1 shown;

[0030] Step 2. On the basis of step 1, this embodiment adopts numerical simulation method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com