Assembly mould and assembly method of angular contact ball bearing

A technology for angular contact ball bearings and molds, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of less and wrong installation of steel balls or spacers, uneven force, and reduced service life of bearings, etc., to achieve Not easy to make mistakes, prevent underfilling and wrong loading, and the effect of accurate ingredient quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

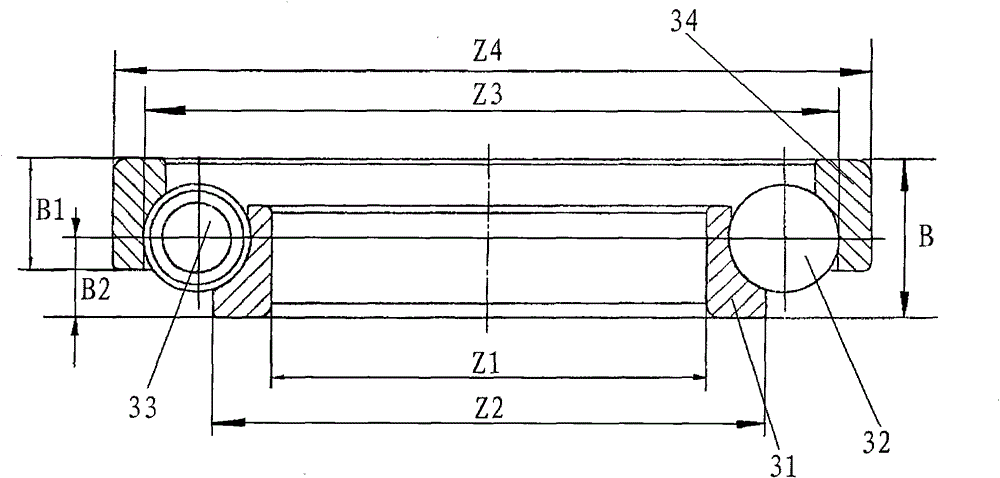

[0033] see figure 1 , the conventional angular contact ball bearing includes an inner ring 31, an outer ring 34, a plurality of steel balls 32 and spacers 33 with the same number of steel balls. There is a channel, steel balls 32 and spacer blocks 33 are arranged in the channel on the outer peripheral surface of the inner ring 31 at intervals, and the outer ring 34 is thermally sleeved on the periphery of the steel balls 32 and spacer blocks 33 after being heated.

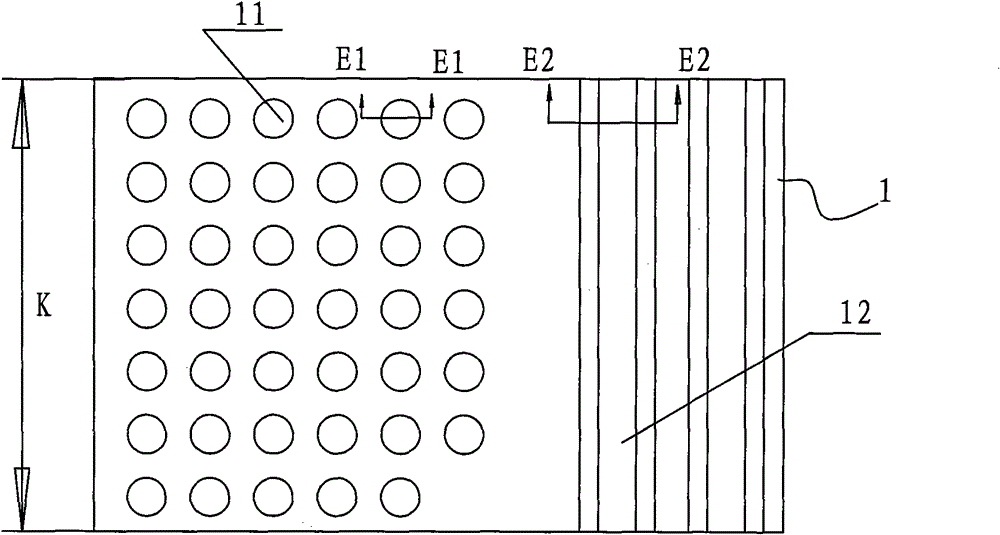

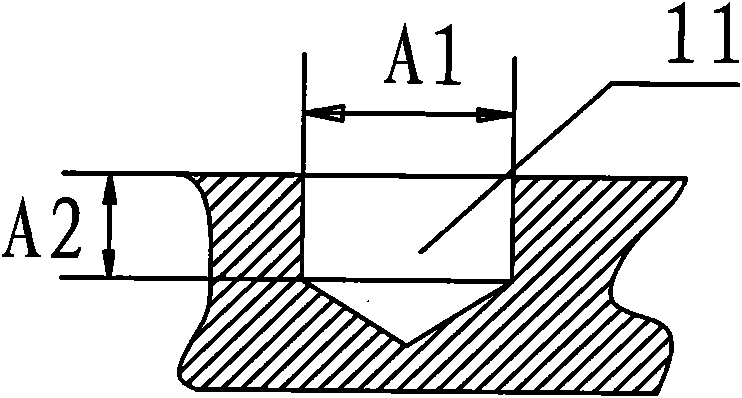

[0034] The assembly mold of the angular contact ball bearing of the present invention includes a counting template and an error-proofing mold, and the material of the counting template and the error-proofing mold is bakelite or a plastic plate.

[0035] see again Figure 2 to Figure 4 , the counting template 1 is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com