Refrigeration cycle apparatus and hot water heater

A circulation device and refrigerant technology, applied in the direction of fluid circulation arrangements, irreversible cycle compressors, reversible cycle compressors, etc., can solve the problem of not being able to maximize the use of the performance of the supercooling heat exchanger 113 and the amount of refrigerant circulation reduction, insufficient heating capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

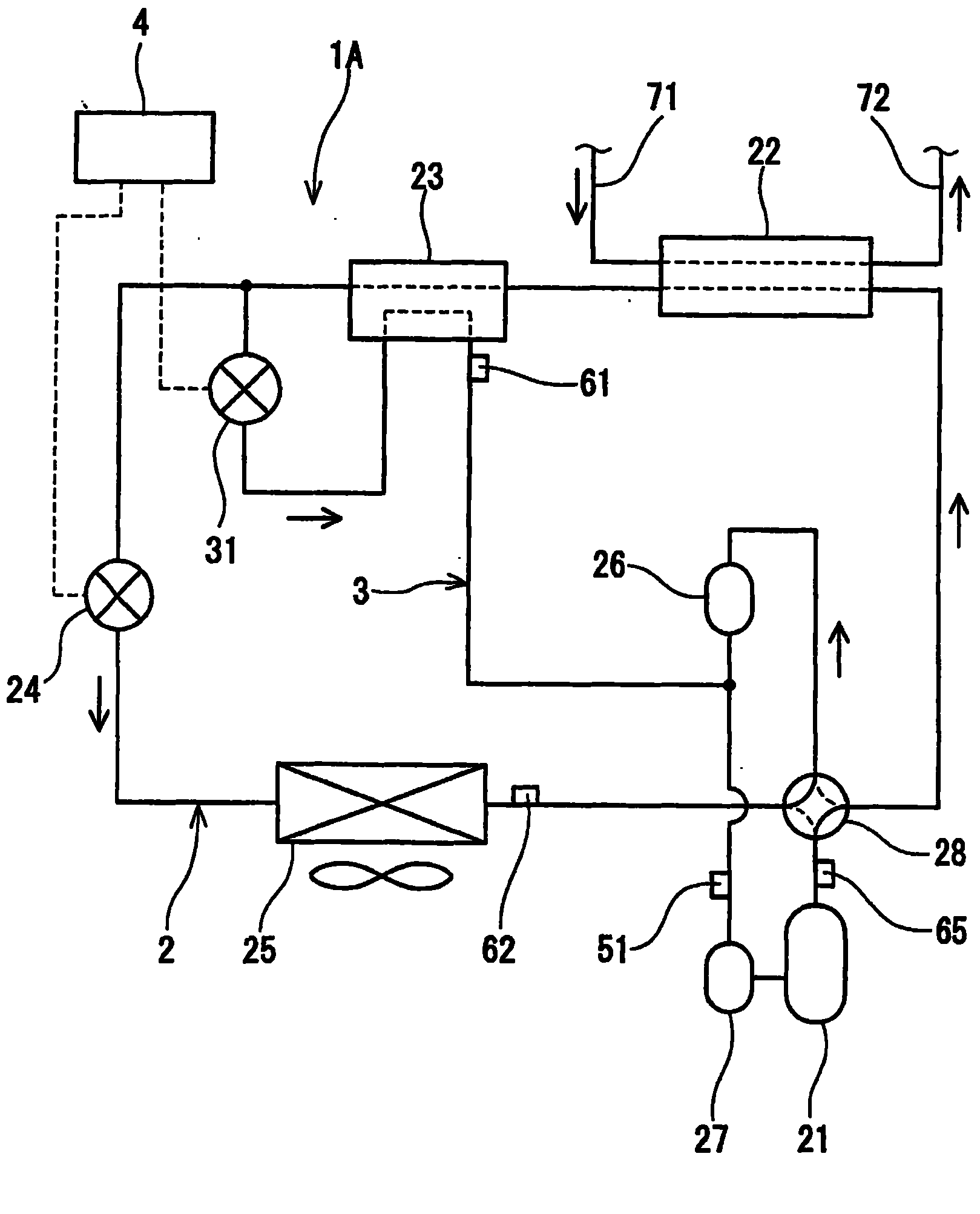

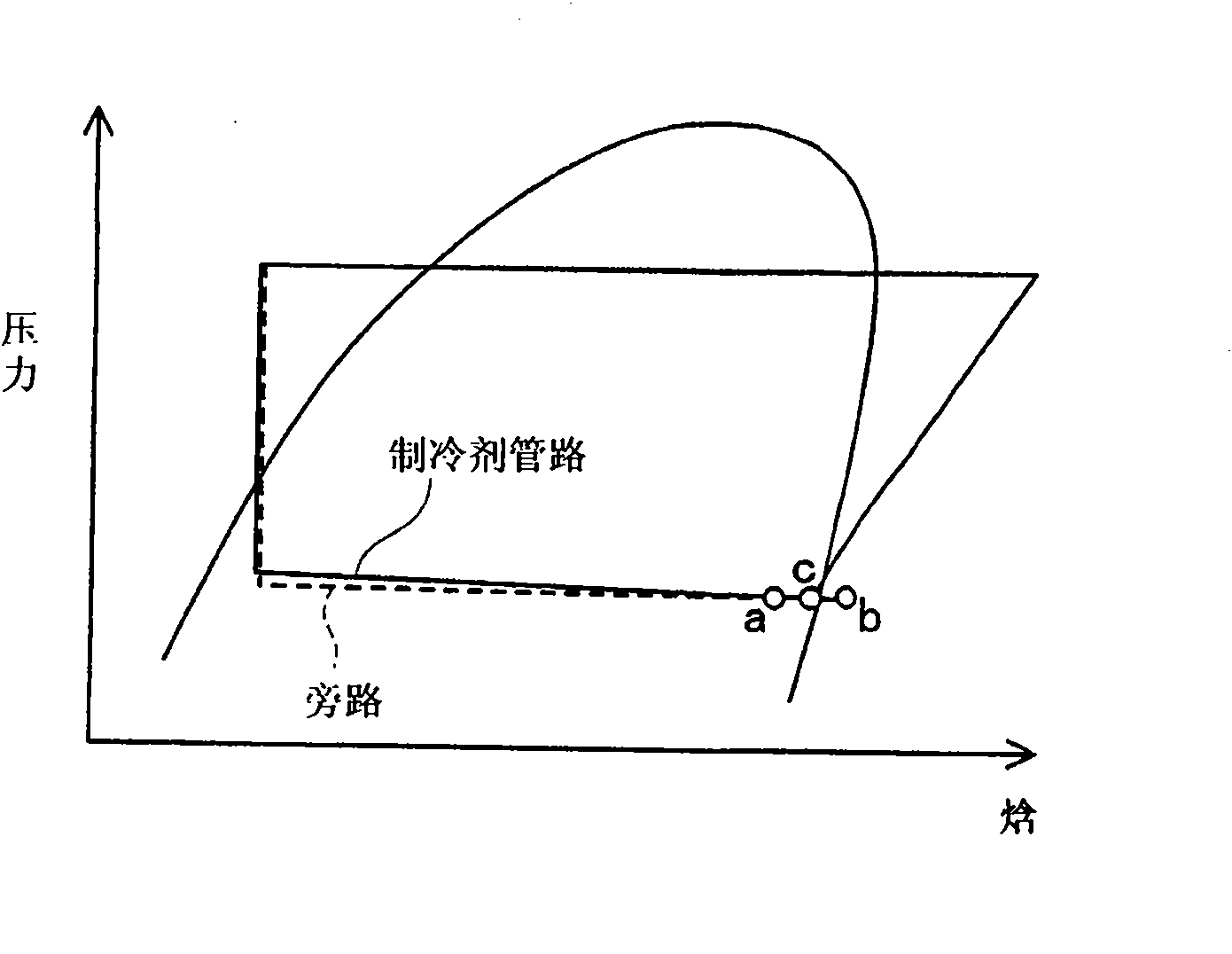

[0036] figure 1 A refrigeration cycle apparatus 1A according to the first embodiment of the present invention is shown. This refrigeration cycle apparatus 1A includes: a refrigerant line 2 for circulating a refrigerant; a bypass 3 ; and a control device 4 . As the refrigerant, for example, a non-azeotropic mixed refrigerant such as R407C, a near-azeotropic mixed refrigerant such as R410A, or a single refrigerant can be used.

[0037] The refrigerant line 2 is formed by connecting a compressor 21 , a condenser 22 , a subcooling heat exchanger 23 , a main expansion valve (main expansion mechanism) 24 , and an evaporator 25 in a tubular shape with piping. In the present embodiment, a sub-accumulator 26 and a main accumulator 27 for separating gas and liquid are provided between the evaporator 25 and the compressor 21 . A four-way valve 28 for switching between a normal operation and a defrosting operation is provided in the refrigerant line 2 .

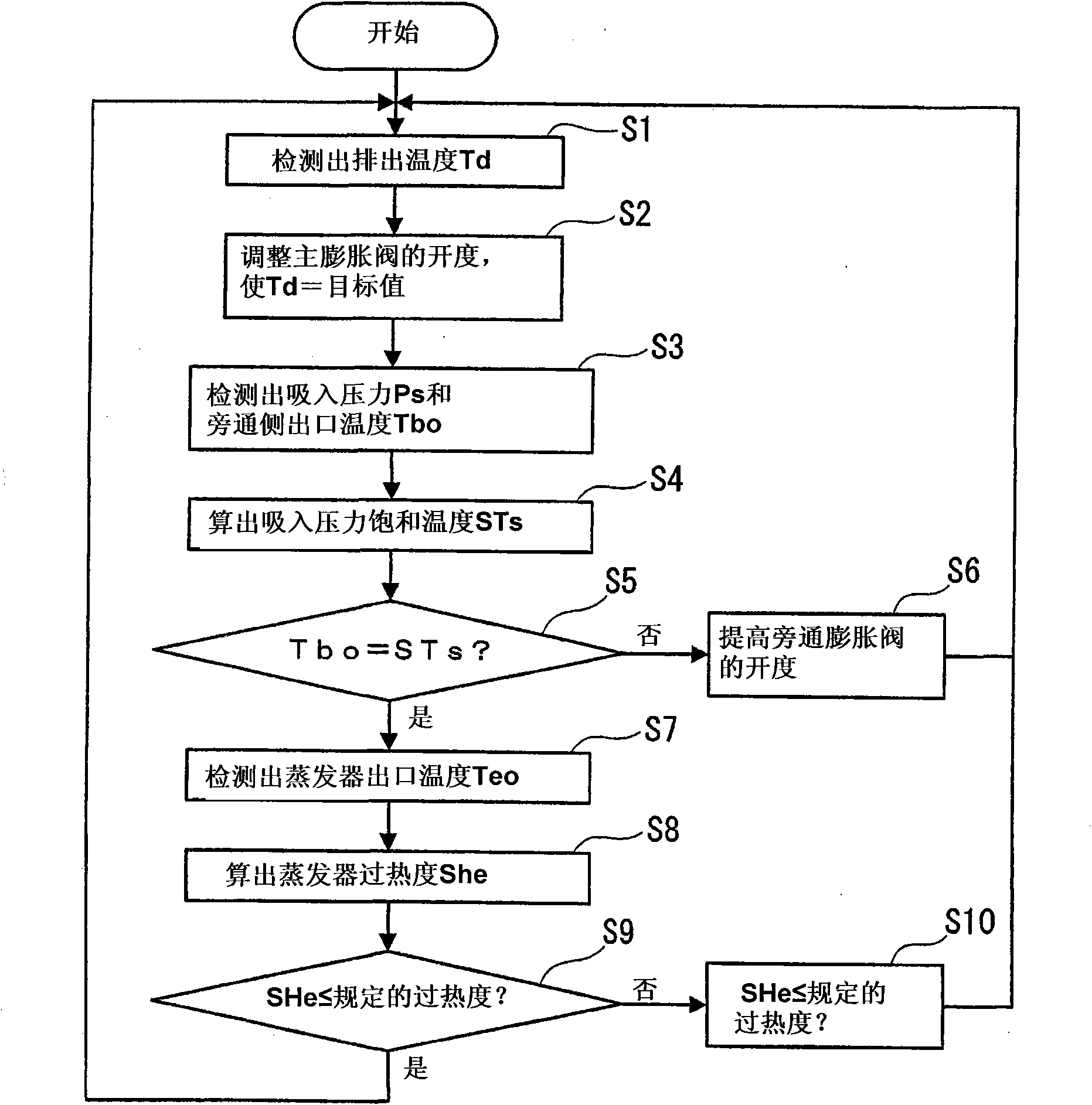

[0038] In this embodiment, th...

no. 2 Embodiment approach

[0068] Figure 4 A refrigeration cycle apparatus 1B according to a second embodiment of the present invention is shown. In this embodiment, the same members as those in the first embodiment are given the same reference numerals, and description thereof will be omitted.

[0069] Also in this embodiment, as in the first embodiment, the control device 4 controls the bypass expansion mechanism 31 during normal operation so that the bypass pipe side outlet temperature Tbo detected by the first temperature sensor 61 becomes The saturated temperature STs under the pressure of the refrigerant sucked into the compressor 21, and the degree of superheat SHe at the outlet of the evaporator 25 calculated from the outlet temperature Teo of the evaporator detected by the second temperature sensor 62 is set in advance. below the specified superheat. However, in the present embodiment, the control device 4 detects that the bypass pipe side outlet temperature Tbo detected by the first tempera...

other Embodiment approach

[0084] In the above-mentioned first and second embodiments, the main expansion valve 24 is controlled so that the discharge temperature Td becomes the target value, however, the method of controlling the main expansion valve 24 is not limited to this. For example, the main expansion valve 24 may be controlled so that the pressure of the refrigerant discharged from the compressor 21 becomes a target value. Alternatively, the main expansion valve 24 may also be controlled according to the degree of superheat at the outlet of the compressor 21 or the degree of subcooling at the outlet of the condenser 22 .

[0085] The bypass 3 does not need to branch from the refrigerant line 2 between the subcooling heat exchanger 23 and the main expansion valve 24 , and may branch from the refrigerant line 2 between the condenser 22 and the subcooling heat exchanger 23 .

[0086] Furthermore, the main expansion mechanism and the bypass expansion mechanism of the present invention do not have t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com