Abnormity diagnosis equipment for crank angle sensor

A technology of crank angle sensor and abnormal diagnosis, which is applied in the direction of mechanical equipment, conversion sensor output, electrical control, etc., and can solve problems such as damage to the engine and deterioration of the working state of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

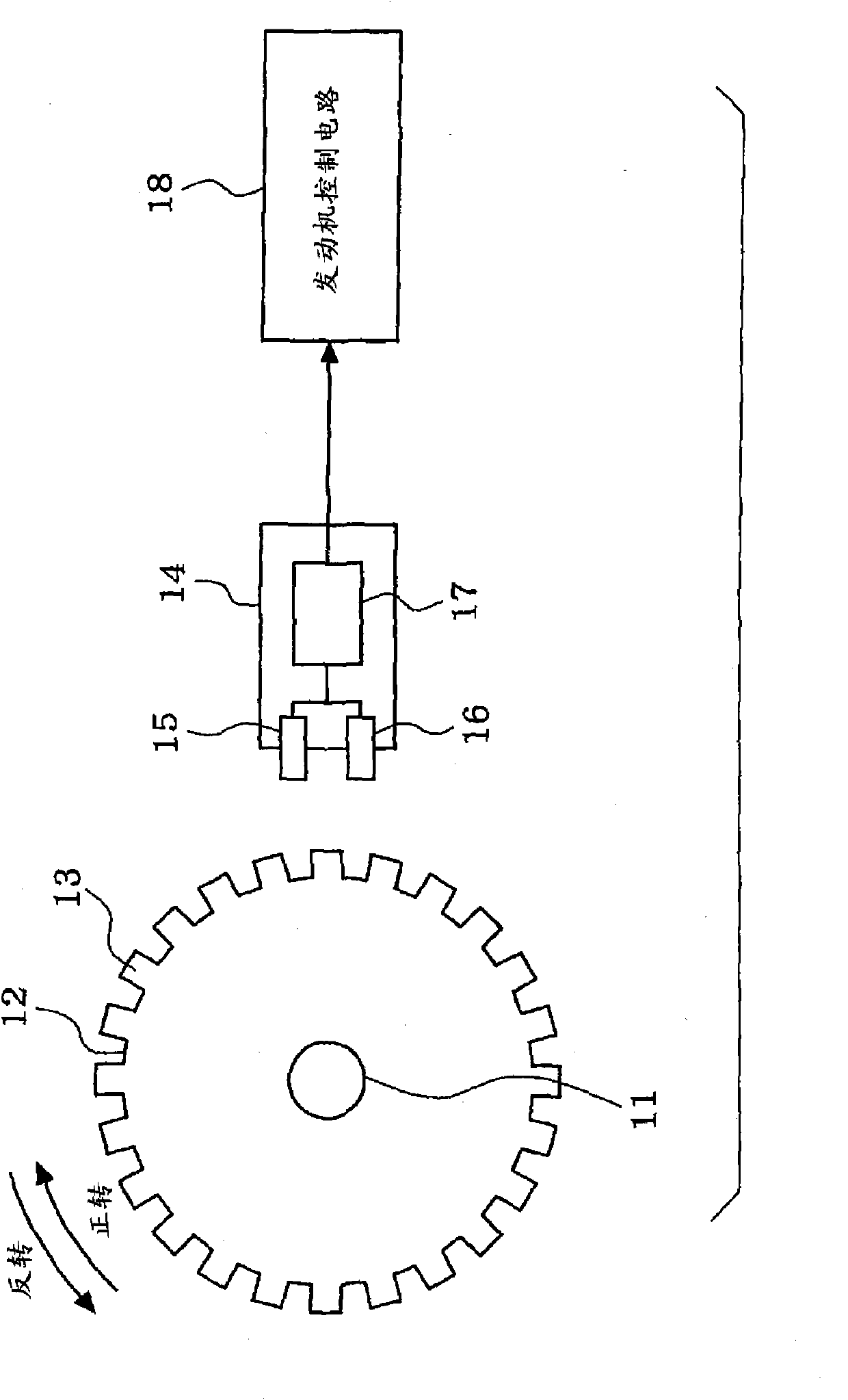

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 The configuration of the crank angle sensing system according to this embodiment will be described.

[0029]A disc-shaped signal rotor 12 is fixed to a crankshaft 11 of an engine (internal combustion engine). A plurality of protrusions 13 are formed on the outer edge portion of the signal rotor 12 at a predetermined crank angle pitch (for example, at a 10CA (crank angle) pitch). A crank angle sensor 14 is fixed to the engine side facing the outer edge portion of the signal rotor 12 . The crank angle sensor 14 has a first sensor 15 (sensor portion) and a second sensor 16 (sensor portion) arranged along the outer edge portion of the signal rotor 12 at predetermined crank angle intervals.

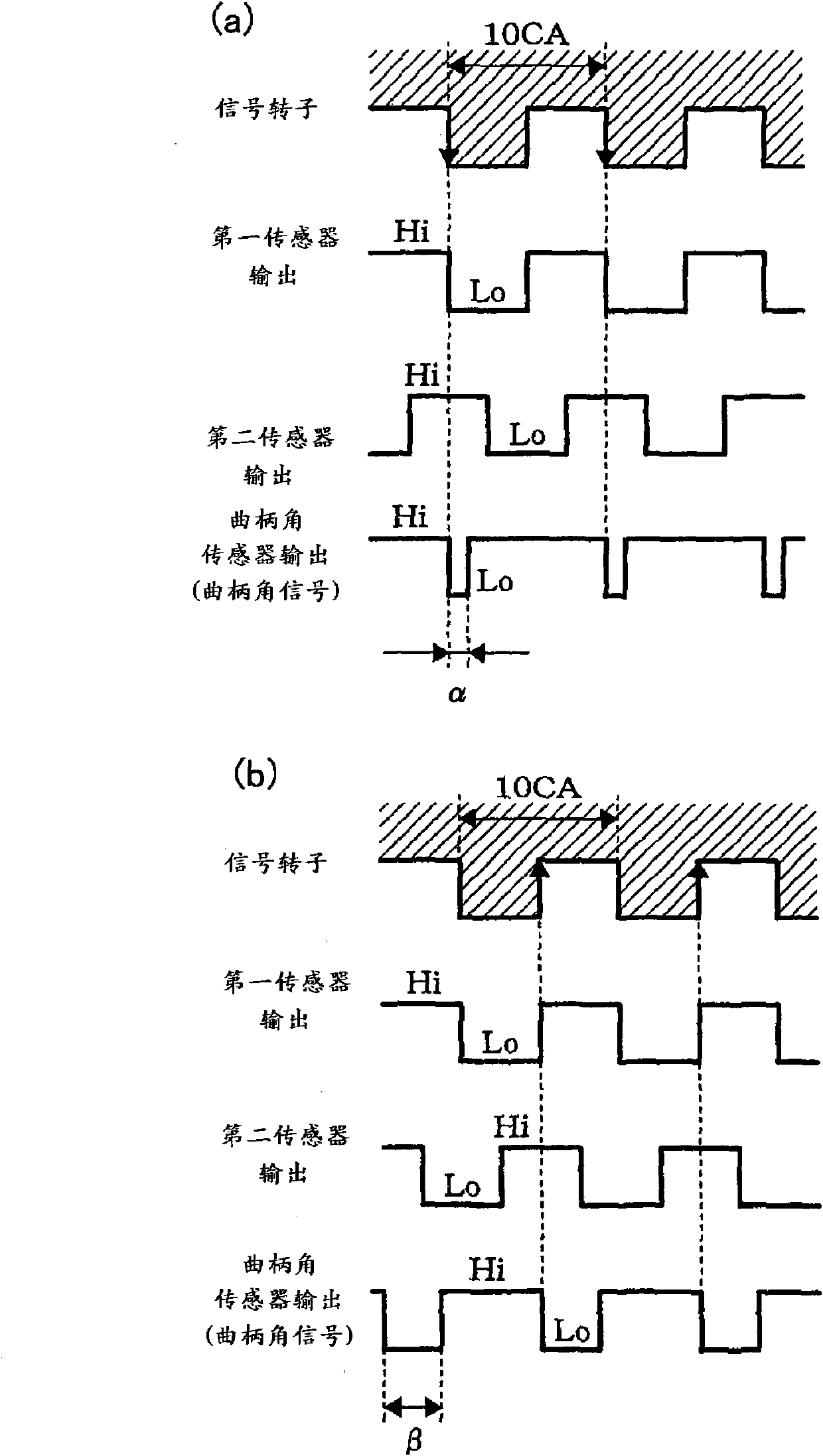

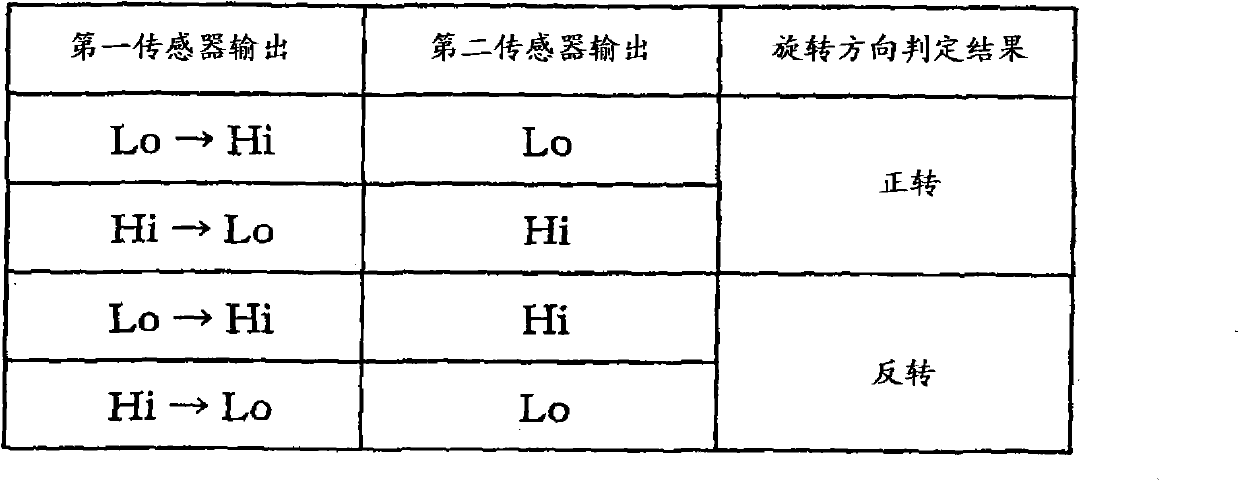

[0030] The sensors 15 , 16 are, for example, electromagnetic induction sensors, Hall sensors or the like. Such as figure 2 As shown, when the protrusion 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com