Unpowered transmission device

A technology of power transmission device and guide device, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of increased production costs, unqualified batches, and poor quality control, so as to reduce unqualified products , Improve production efficiency and pass rate, improve work efficiency and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

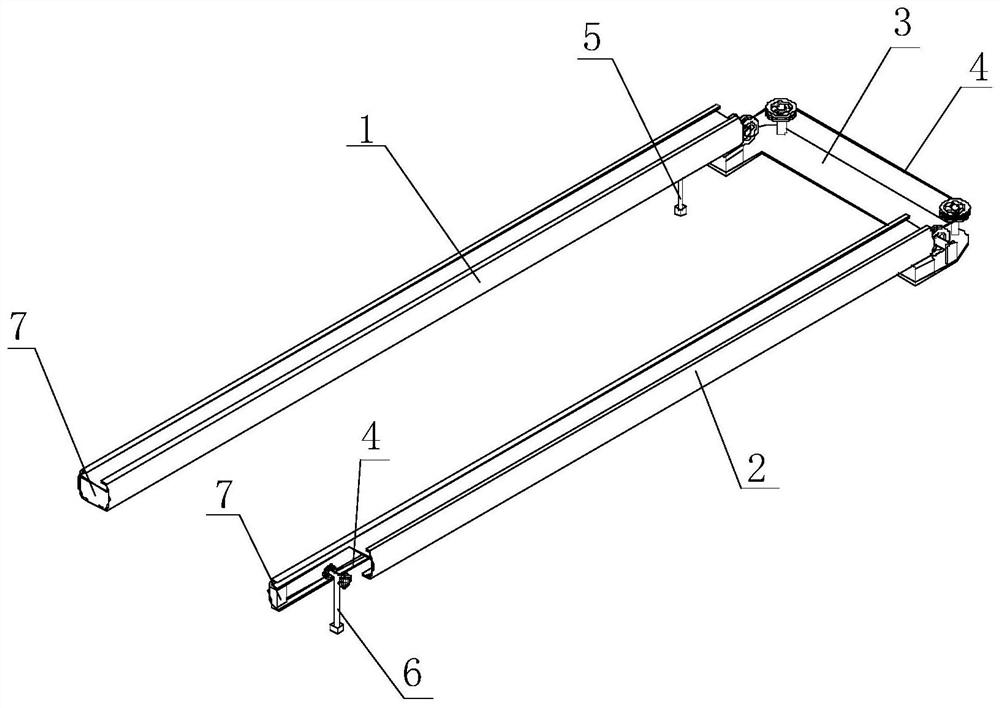

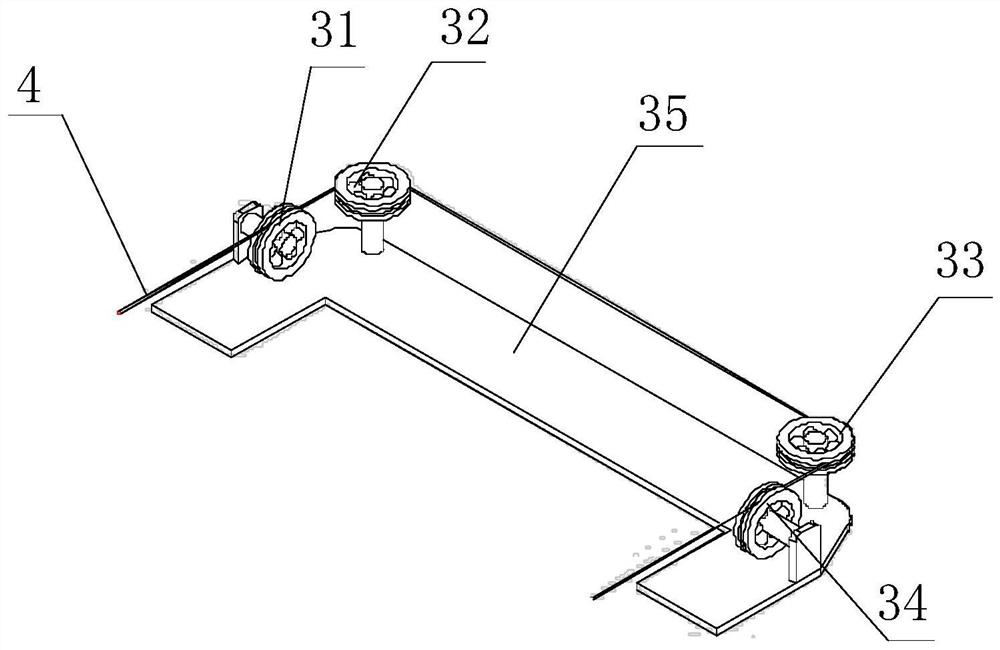

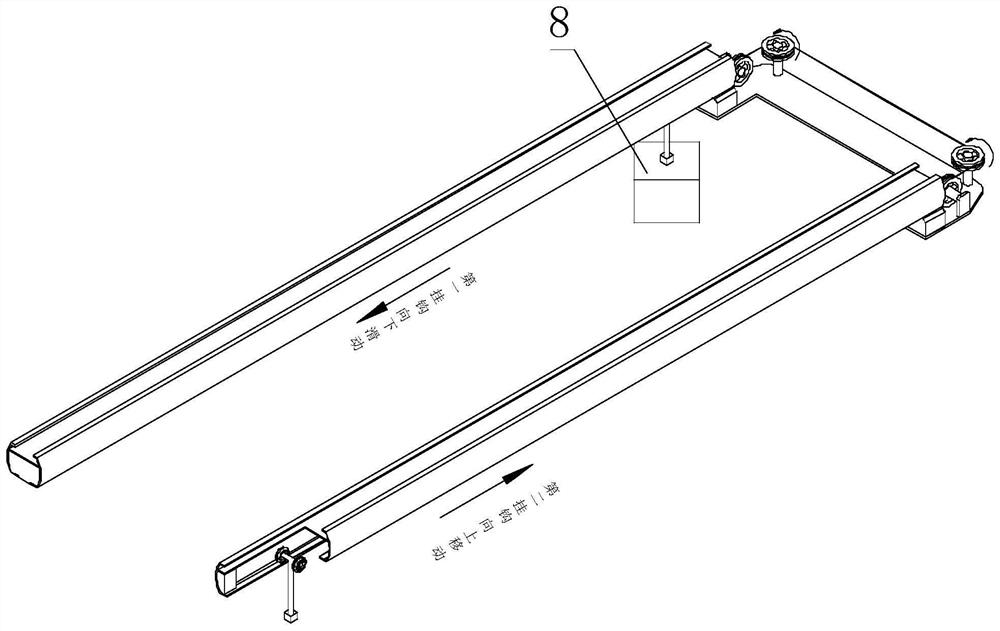

[0014] Such as Figure 1-2 As shown, the lean single-piece flow non-powered transmission device of the present invention includes a first guide rail 1, a second guide rail 2, a guide device 3, a traction line 4, a first hook 5, a second hook 6 and a buffer member 7, wherein the first One end of a guide rail 1 and the second guide rail 2 is connected by a guide device 3, and a buffer member 7 is respectively installed on the other end of the first guide rail 1 and the second guide rail 2; the first hook 5 is arranged in the first guide rail 1, and the second hook 6 is set in the second guide rail 2, and both the first hook 5 and the second hook 6 are set on the pulling wire 4, the first hook 5 and the second hook 6 are pulled by the pulling wire 4 and guided by the guide device 3 The bottom can move up and down in the first guide rail 1 and the second guide rail 2 respectively, and the buffer member 7 prevents the first hook 5 and the second hook 6 from continuing to move and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com