Label printing method

A technology for labeling and printing requests, applied in the direction of digital output to the printing unit, etc., can solve the problems of the first type of label printing request blocking, relatively high time requirements, and large number of labels to be printed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

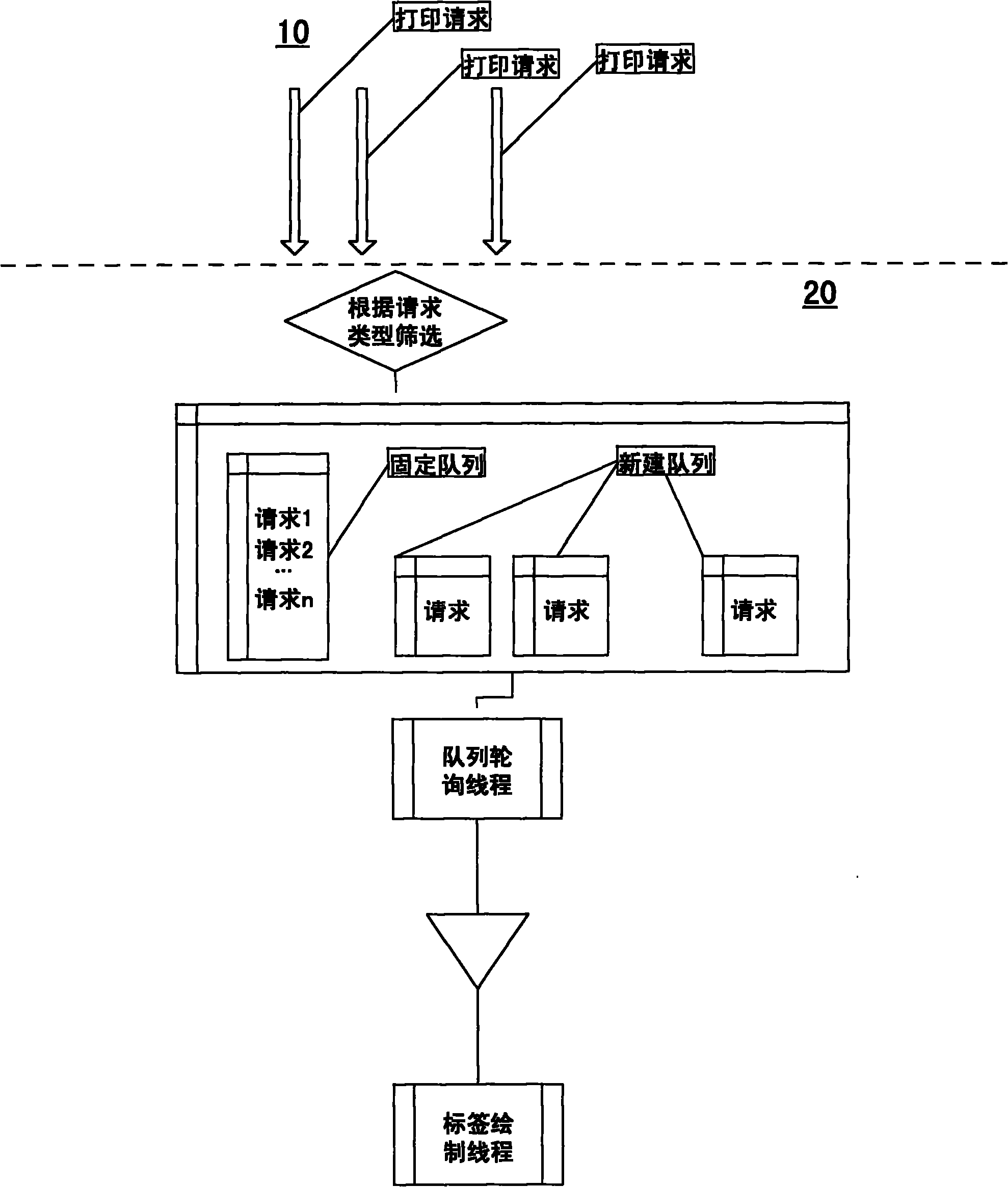

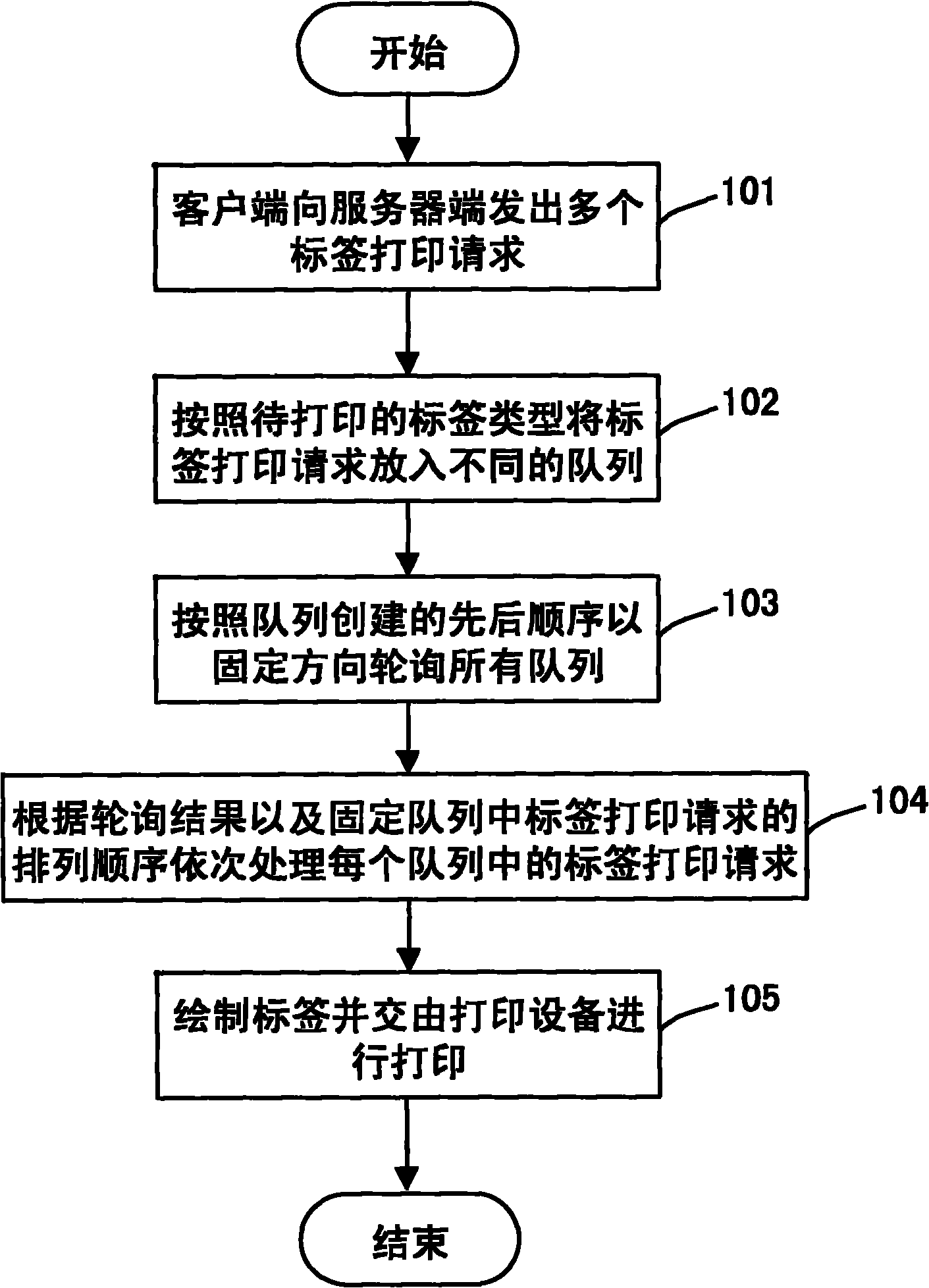

[0021] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the system architecture operated by the label printing method of the present invention, figure 2 It is a flow chart of the steps of the label printing method of the present invention, such as figure 1 and figure 2 As shown, a label printing method provided by the present invention includes the following steps:

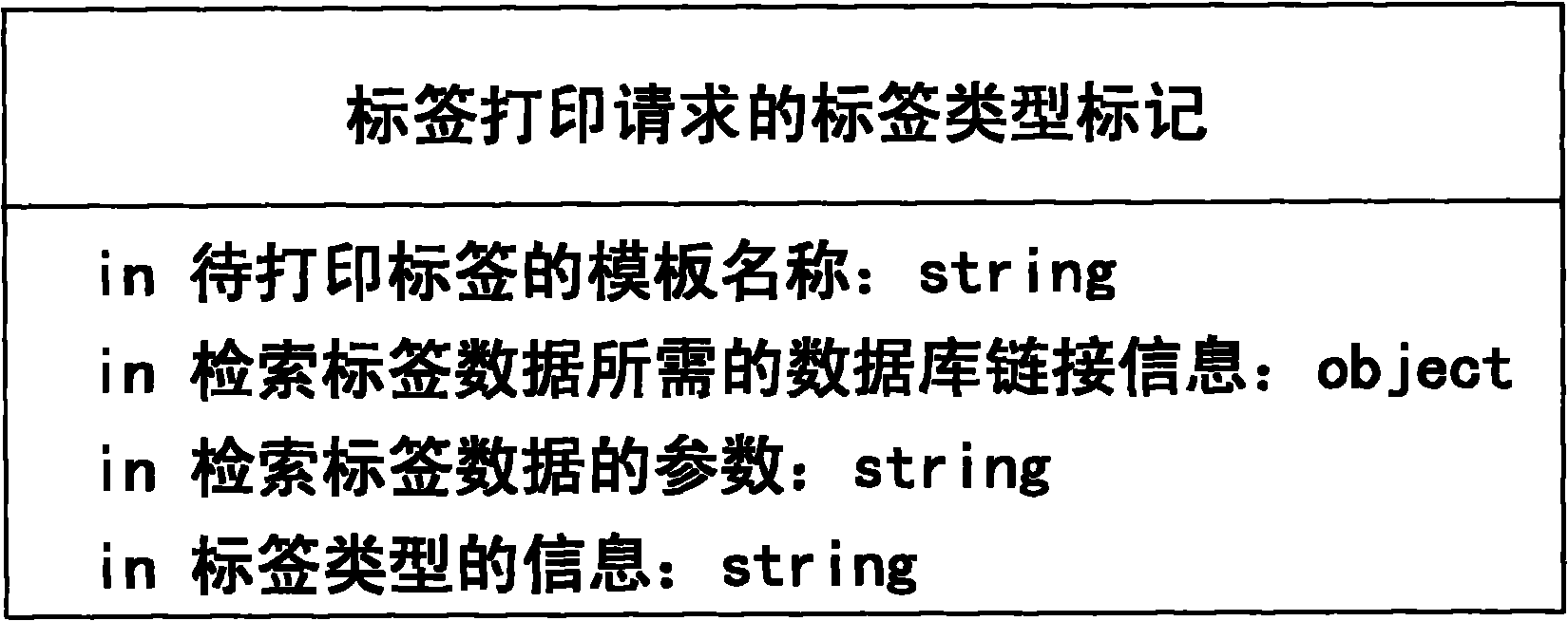

[0022] The client 10 sends a plurality of label printing requests to the server 20, wherein each label printing request has a label type mark (step 101);

[0023] After the server end 20 receives each label printing request, it screens according to the type of the label printing request, and puts the label printing request into different queues according to the label type to be printed, wherein for the label types that need to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com