Foldable derrick structure for a ship

A technology for towers and ships, applied in the field of foldable tower structures, can solve problems such as difficulty in lowering the tower height, difficulty in dismantling the tower, and deterioration of floating stability, so as to reduce the center of gravity, improve floating stability, reduce time and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Exemplary embodiments of the present disclosure will now be described in detail with reference to the accompanying drawings. It should be noted that the same reference numerals denote the same components throughout the specification and drawings.

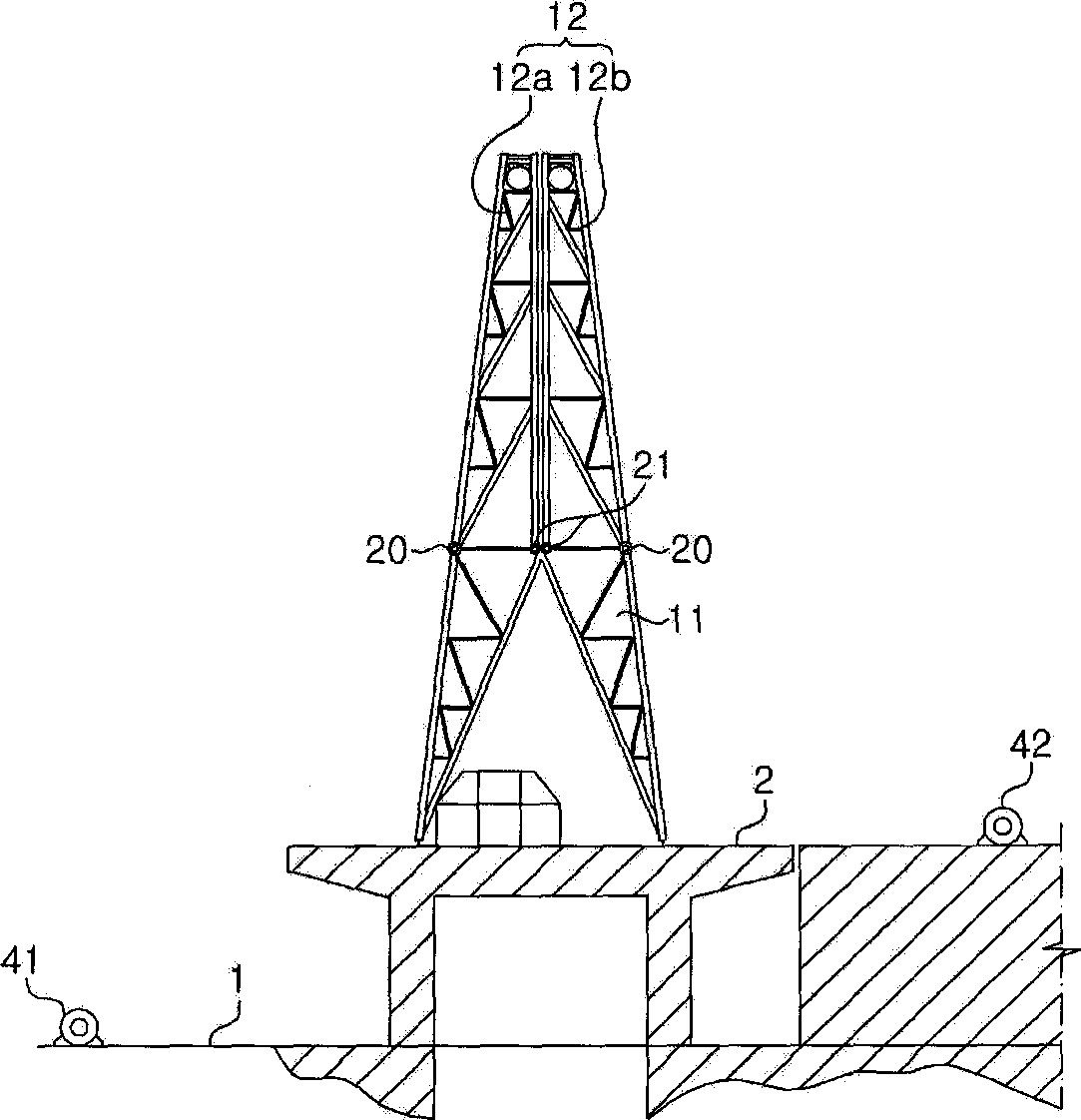

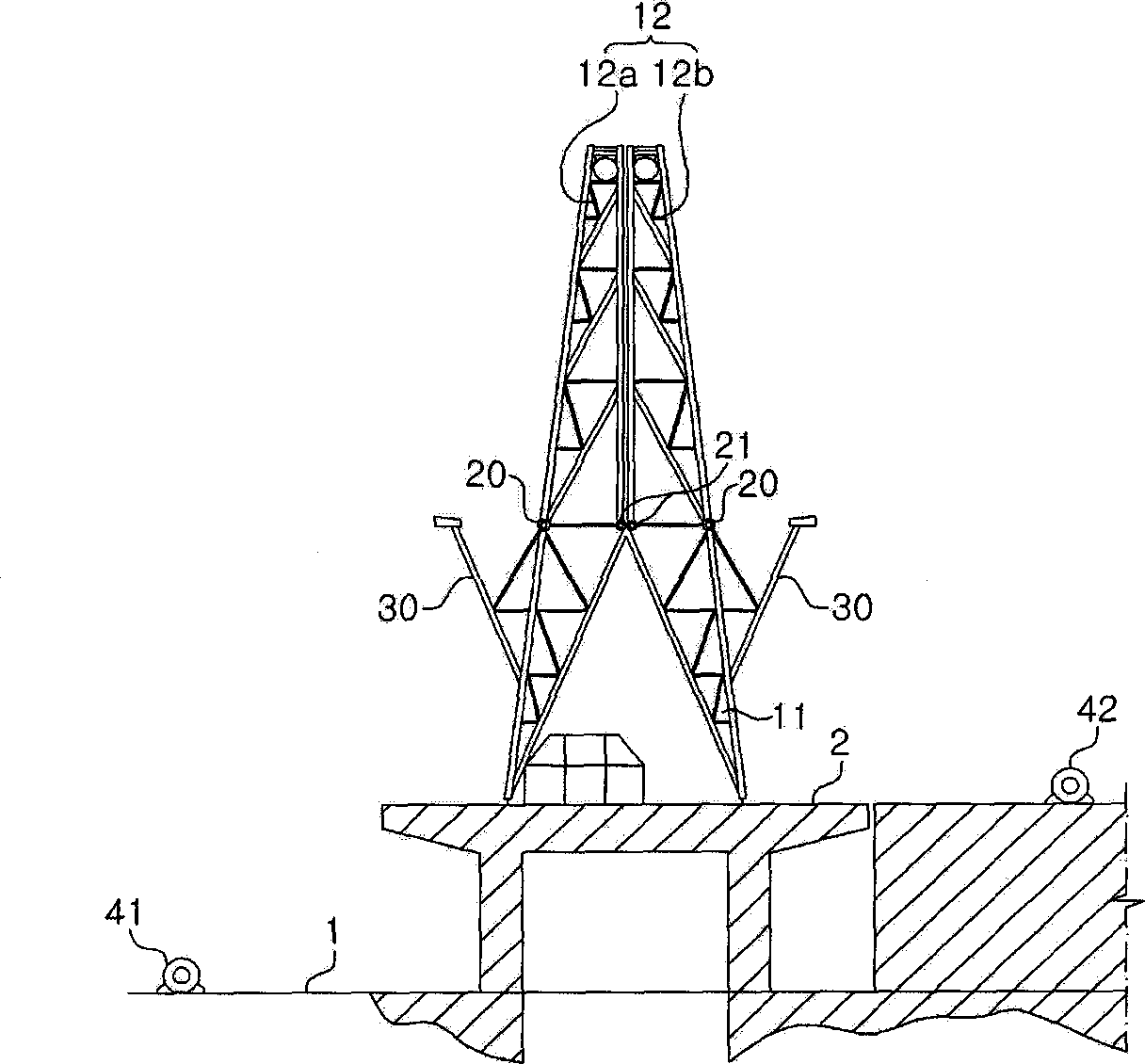

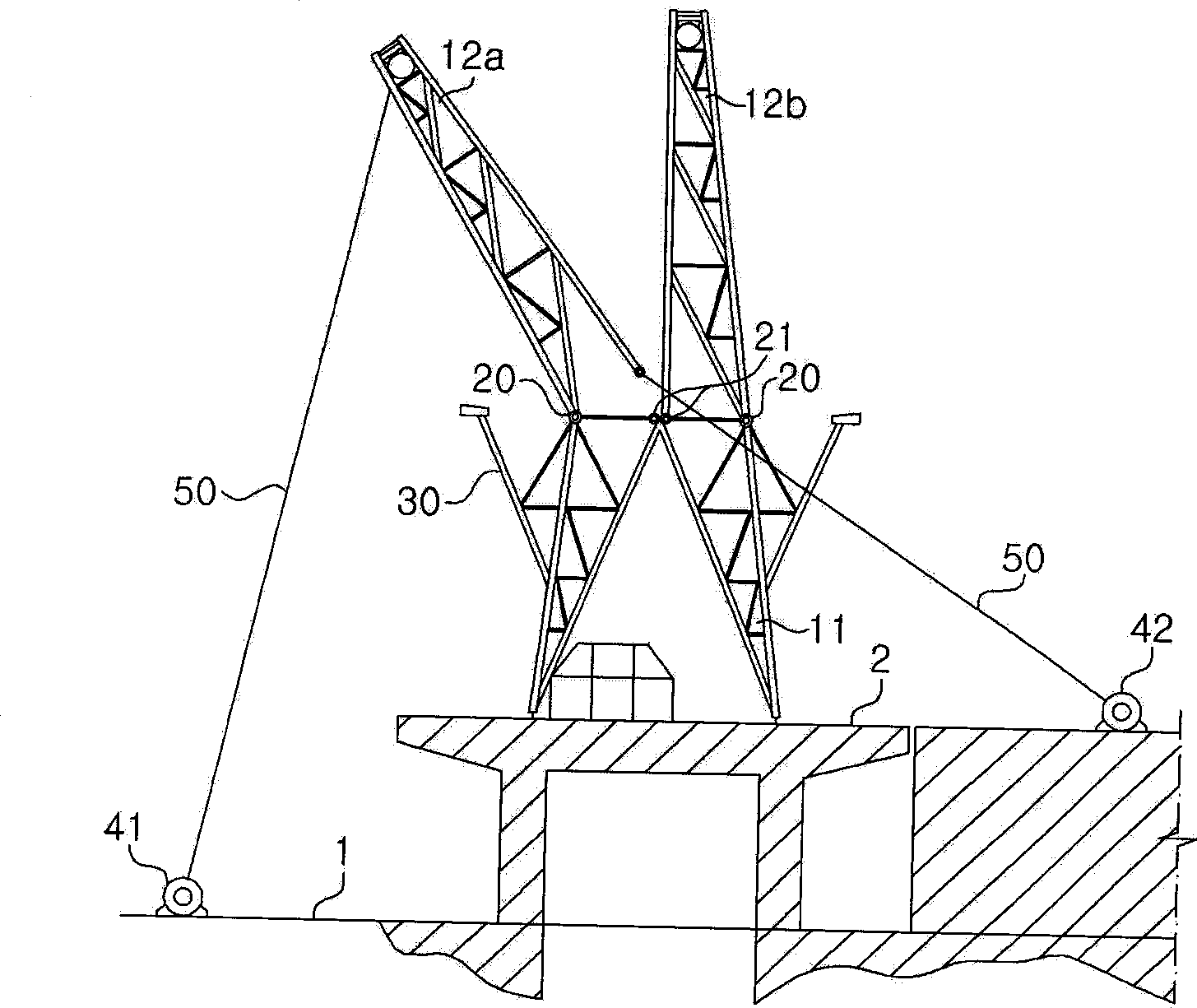

[0036] Figures 1a to 1f show the sequential operation of folding the upper tower part of a foldable tower structure for a vessel according to one embodiment, and Figures 2a to 2f show the upper tower part to be folded according to this embodiment Sequential operation from erect to initial state.

[0037] Generally, a tower is a tower crane built on a ship, such as a drill floor of a drilling ship, so that all drilling equipment can be concentrated on the tower, and the tower is configured to raise or lower the drilling equipment, such as a drill pole etc.

[0038] Referring to Figure 1a, the tower according to this embodiment consists of two parts, an upper tower part 12 (12a, 12b) and a lower tower part 11, which are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com