Process for recycling acetonitrile from wastewater by using clapboard tower through azeotropic distillation

A clapboard tower and acetonitrile technology, which is applied in the field of high-purity acetonitrile, can solve the problems of complex process, low product purity, and large equipment investment, and achieve high product purity, broad application prospects, and high energy consumption.

Inactive Publication Date: 2011-05-04

HEBEI UNIV OF TECH

View PDF3 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the industrial wastewater containing acetonitrile is difficult to separate due to the existence of acetonitrile-water completely miscible binary azeotropic system (azeotropic composition 85%, water 15%, V/V, azeotropic point 76°C)

The traditional acetonitri

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

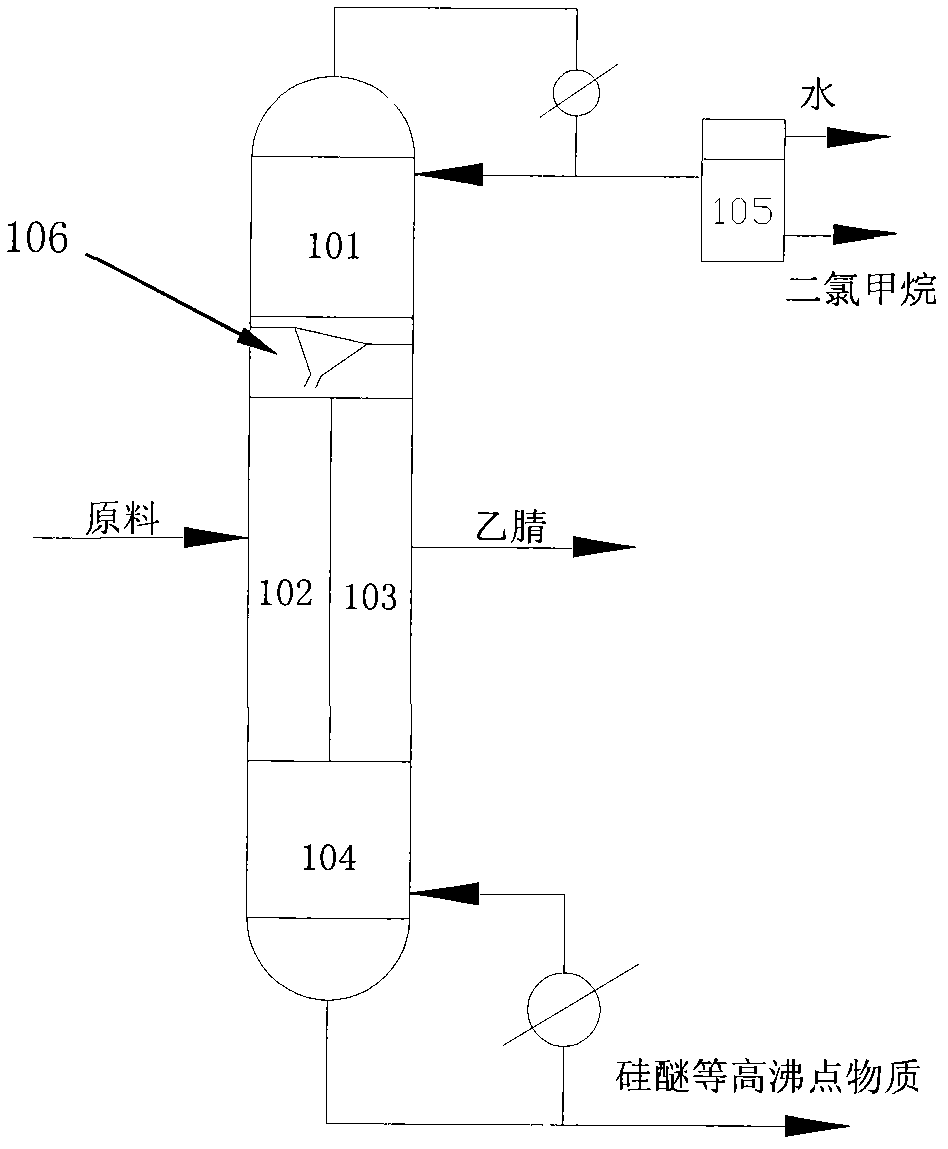

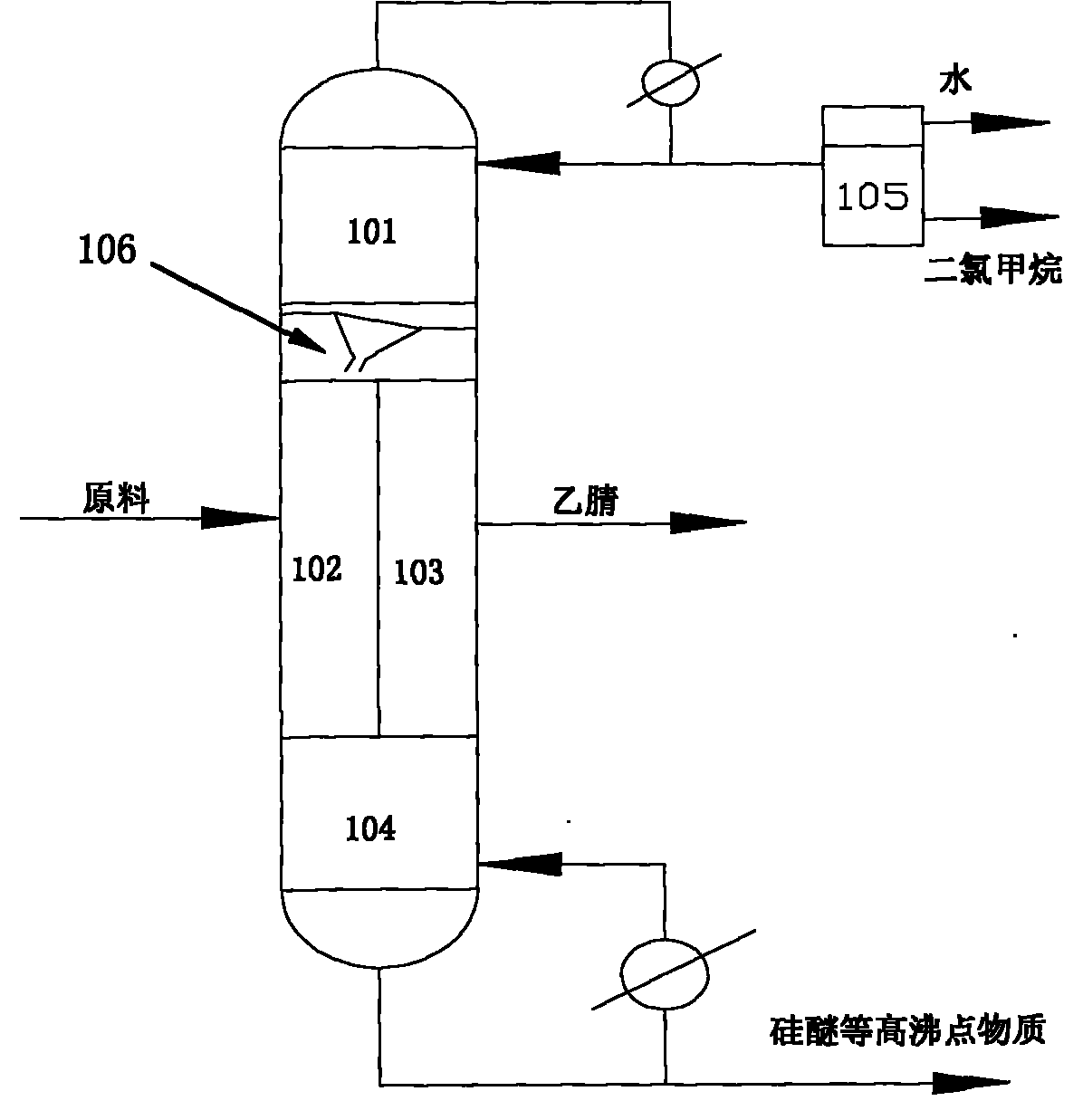

The invention relates to a process for recycling acetonitrile from wastewater by using a clapboard tower through azeotropic distillation. Trace high boiling point materials of acetonitrile, dichloromethane, silicon ethers and DMF (Dimethyl Formamide) in wastewater are recycled when azeotropic distillation is carried out by using a clapboard tower, continuous feed is carried out at a prefractionation section of the clapboard tower for azeotropic distillation, and overhead fractions enter a phase splitting tank to respectively obtain dichloromethane and water, enter a main tower side-draw of the clapboard tower to obtain acetonitrile, and enter a tower bottom to obtain the high boiling point materials of silicon ethers and the like. Components with higher purity are respectively obtained atthree positions of the tower top, the side-draw and the tower bottom of the clapboard tower in an azeotropic distillation manner by using a single-tower, and continuous production is realized. The process disclosed by the invention is especially suitable for processing low-concentration acetonitrile wastewater (acetonitrile mass concentration is not more than 50 percent); and the process can greatly reduce the energy consumption of the low-concentration acetonitrile wastewater during the treatment while ensuring the acetonitrile yield, and has remarkable practicability and economic benefit.

Description

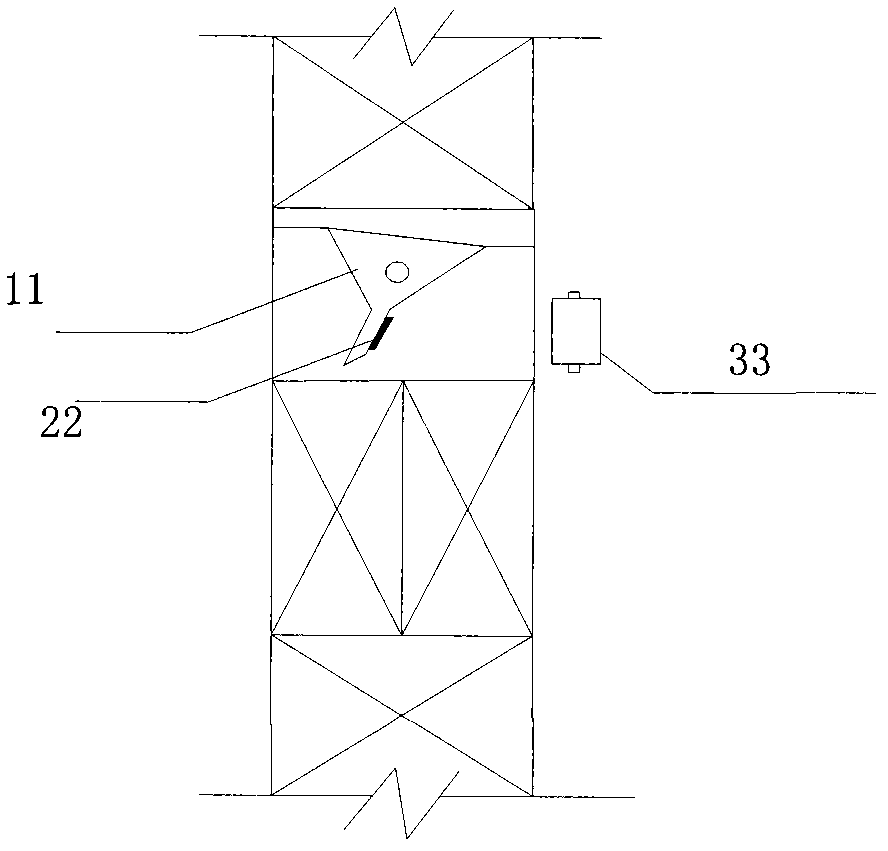

technical field [0001] The invention relates to a process for recovering acetonitrile from waste water by azeotropic rectification using a partition tower, specifically using a partition tower to recover acetonitrile from waste water containing low-concentration acetonitrile, dichloromethane, DMF and silicon ether and other high-boiling substances. High purity acetonitrile is recovered. Background technique [0002] Wastewater in the chemical industry contains acetonitrile, dichloromethane, water, silicone ether, N, N-dimethylformamide (DMF) and other trace high-boiling substances, which belong to the multivariate azeotropic system and are difficult to separate. The original separation process adopts a multi-tower process, which requires large equipment investment and high energy consumption, and cannot meet the requirements of energy-saving and efficient chemical separation processes. [0003] The clapboard column is a fully thermally coupled rectification column. Its stru...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C255/03C07C253/34C07C19/03C07C17/386C02F1/04

Inventor 李春利方静王荣良刘继东李莉洁

Owner HEBEI UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com