Rotating short joint for oil well logging

A rotary sub-joint and petroleum logging technology, which is applied in measurement, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of heavy cable bearing and instrument drop, so as to improve reliability, prolong service life, and ensure The effect of not loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

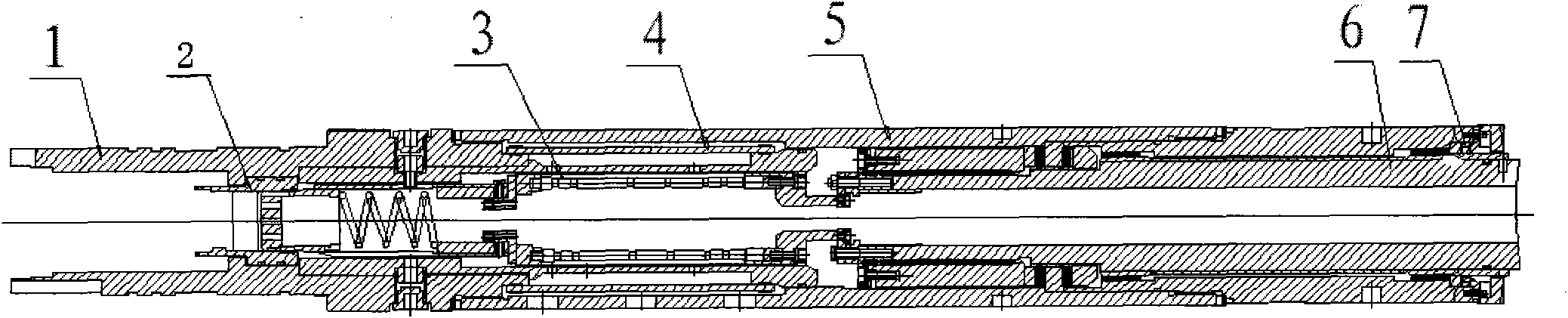

[0019] The structure diagram of this embodiment is shown in figure 1 . The connection relationship is that the upper joint 1 and the connecting piece 5 are connected by threads, and the connecting piece 5 and the rotary joint 6 are tightly connected by threads to form the main structure of the instrument. The upper joint 1 is provided with a first pressure-bearing joint, and the rotary joint 6 is provided with a second pressure-bearing joint.

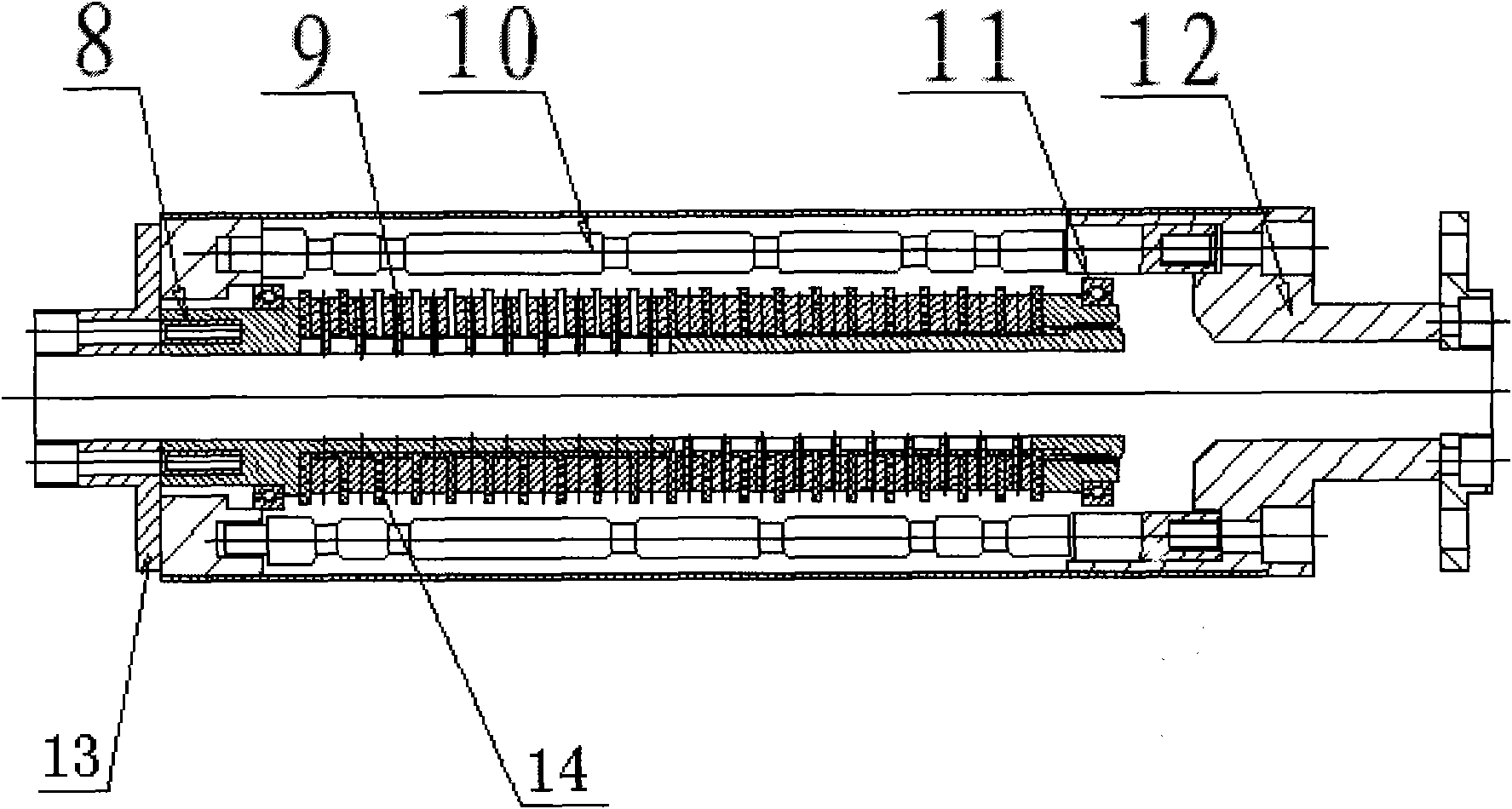

[0020] In order to ensure the sealing of the instrument, there is a slip ring 3 ( figure 2 ) and the bladder 4, the slip ring 3 is used to ensure the connection of the circuit, and the bladder 4 is used to ensure the extra space brought by the expansion of the downhole preheating silicone oil.

[0021] The structure of the slip ring 3 includes a central shaft 8, a bearing 11, an end cover 13, an I-shaped end cover 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com