Improved inward rotation gear pump

A gear pump and internal rotation technology, which is applied to rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of poor fluidity of high-viscosity materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

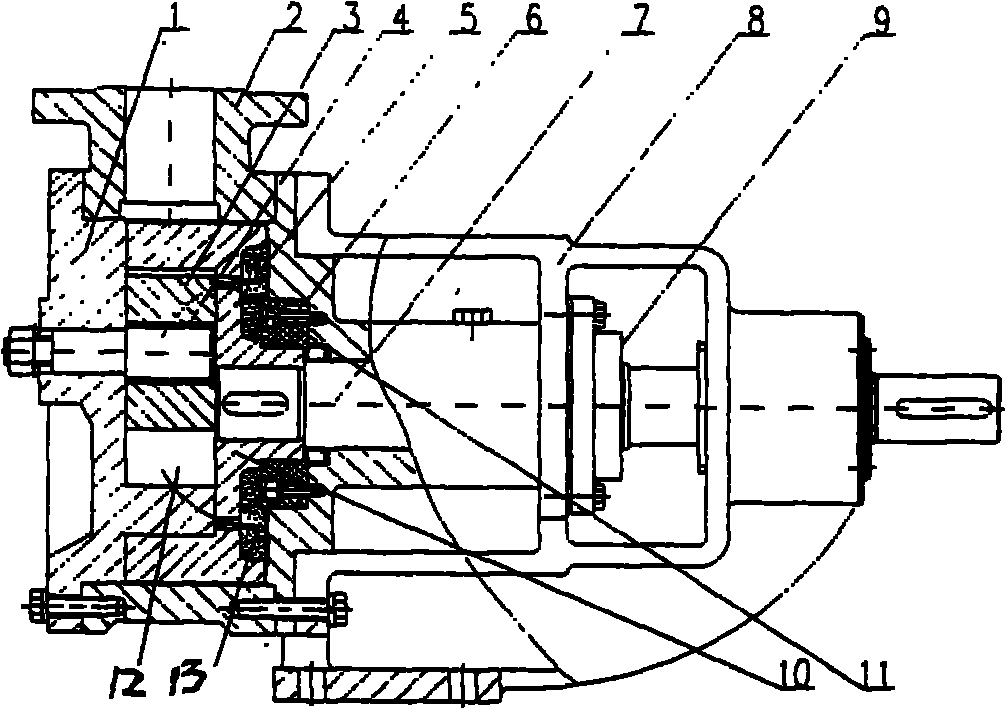

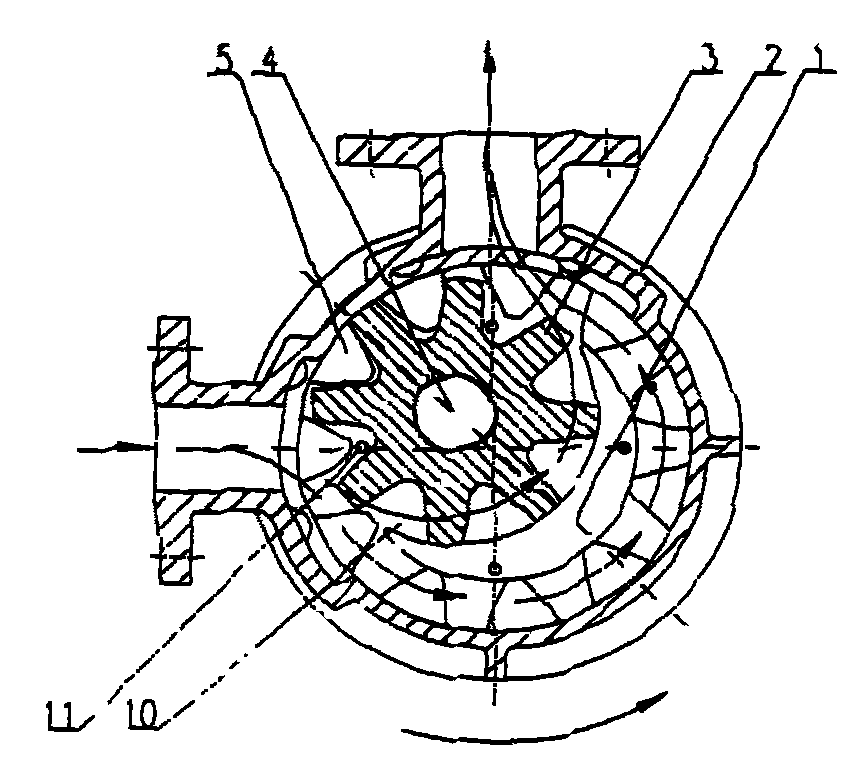

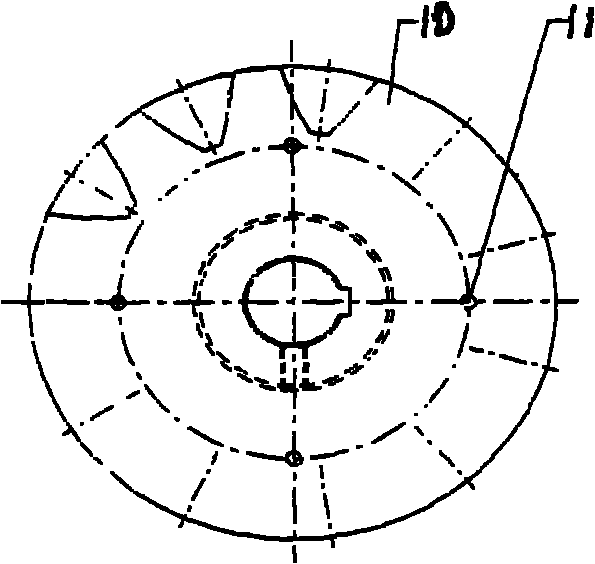

[0011] An improved internal rotation gear pump, including a pump cover 1, a pump casing 2, a driven shaft 4 and a driven gear 3, a driving shaft 7 and a driving gear 5, a pump seat 8, a shaft seal 9, and the abdomen of the driving gear 5 A number of material supply holes 11 are provided on the plate 10. The material supply holes 11 can be straight, oblique cylinder holes or cone holes. The material supply holes 11 communicate with the pump cavity 12 and the material dead zone 13 in the pump cavity. The material dead zone 13 in the pump cavity refers to the area surrounded by the right side of the web 10 of the pump driving gear, the inner surface of the pump casing, and the end face of the pump seat 8. A modified polytetrafluoroethylene sealing ring 6 is added to the left end of the pump seat 8.

[0012] Under the same conditions, the service life of the pump in different media before and after improvement:

[0013]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com