Device and method for automatically metering and calibrating horizontal tank capacity based on standard metal tank

A standard metal measuring device and horizontal tank technology, which is applied in the field of measurement, can solve the problems that the uncertainty of the core component flowmeter needs to be improved, it is difficult to meet the uncertainty, and the measurement requirements are not met, so as to achieve a simple structure and prevent liquid The effect of overflow, which is conducive to the stability of the liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

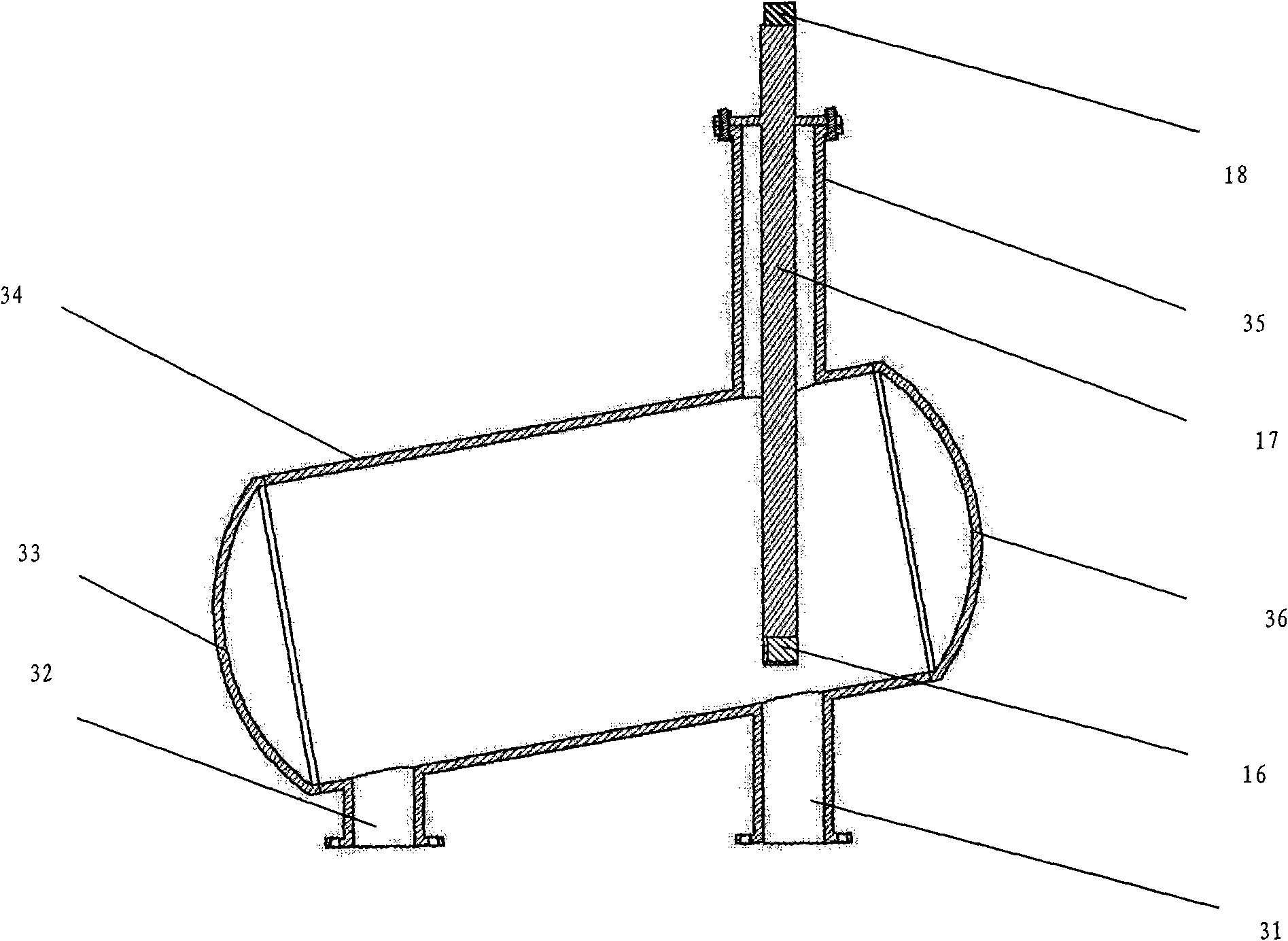

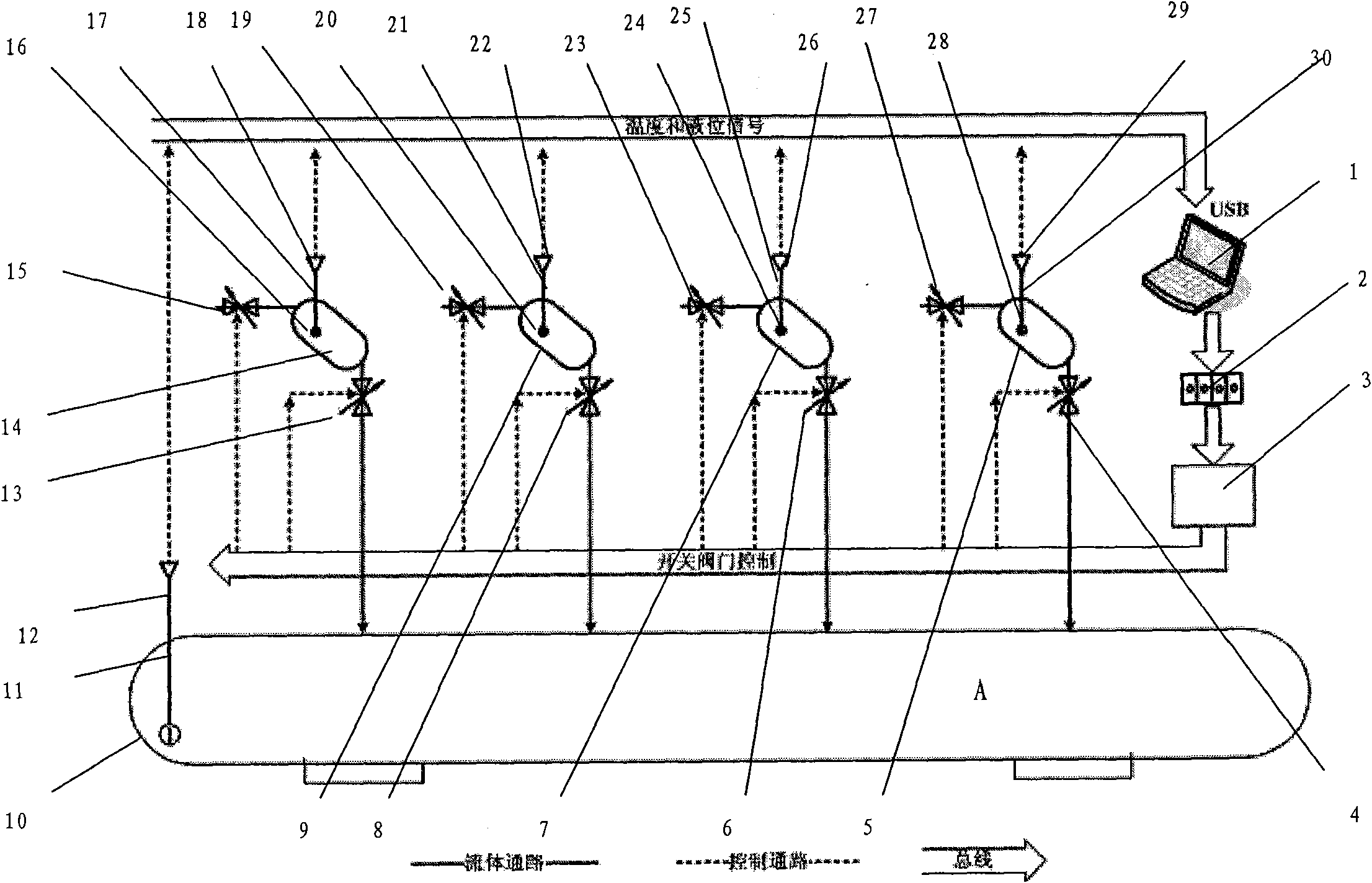

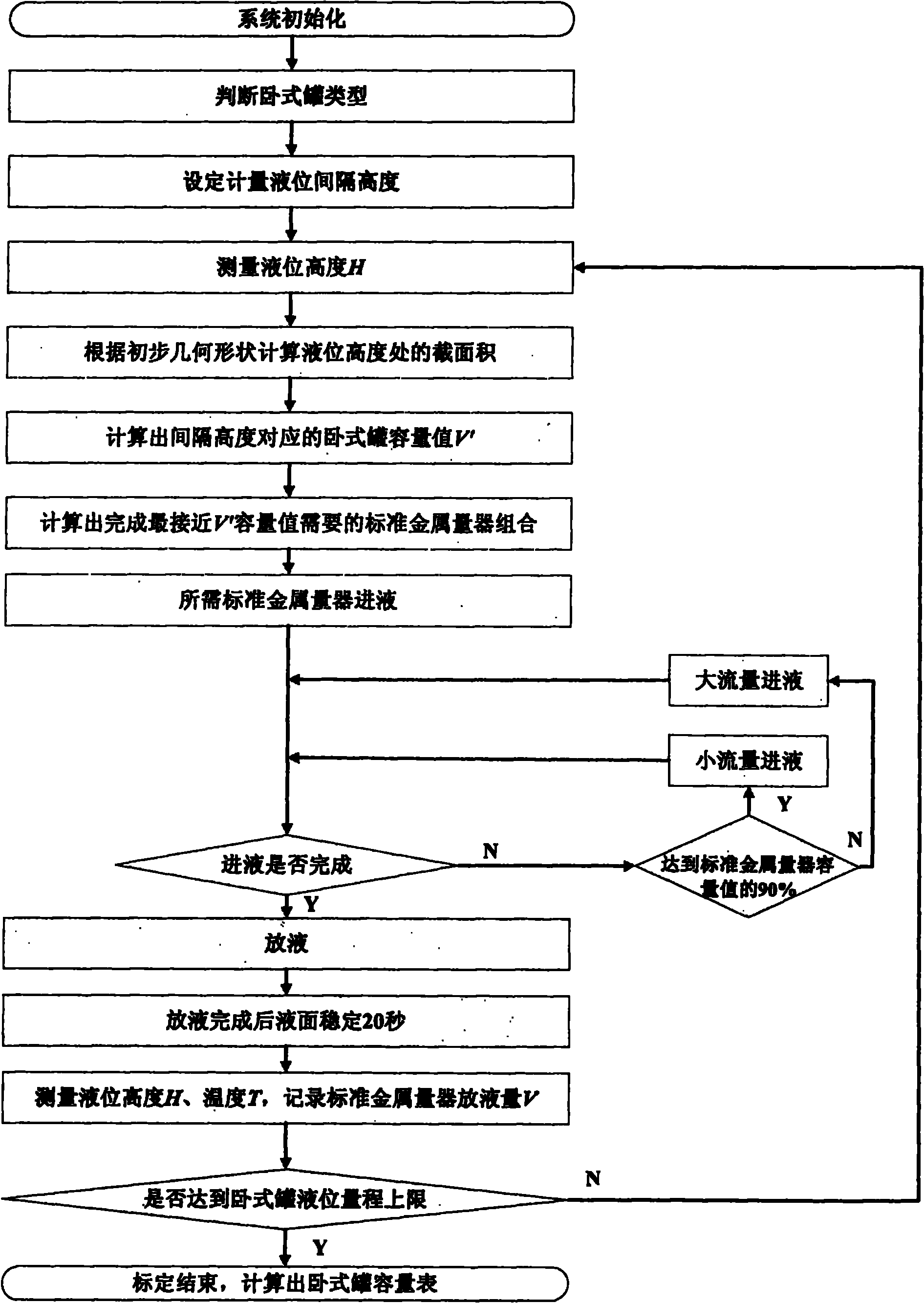

[0053] like figure 2 As shown, the working principle of the system of the present invention is: the present invention includes a computer 1, an I / O card 2, a power amplifier 3, a liquid inlet solenoid valve 15 19 23 27, a liquid discharge solenoid valve 4 6 8 13, and a magnetic telescopic liquid level sensor 11 17 21 25 30 and temperature sensor 10 16 20 24 28, computer 1 controls the output of power amplifier 3 through I / O card 2, power amplifier 3 is connected to solenoid valve 15 19 23 27 4 6 8 13, solenoid valve 15 19 2327 4 6 8 13 are connected to the liquid inlet 31 and the liquid discharge port 32 of the standard metal gauge 5 7 9 14, and the computer 1 controls the opening and closing of the electromagnetic valve to realize the liquid inlet and discharge of the standard metal gauge. The magnetic telescopic liquid level gauge 11 and the temperature sensor 10 are placed at the metering port of the horizontal tank A, and connected to the computer 1 through the USB port t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com