Special insulated protection shell of mutual inductor

A technology for transformers and rear shells, which is applied in the field of special insulating shells for transformers, and achieves the effects of stable performance, strong practicability, and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

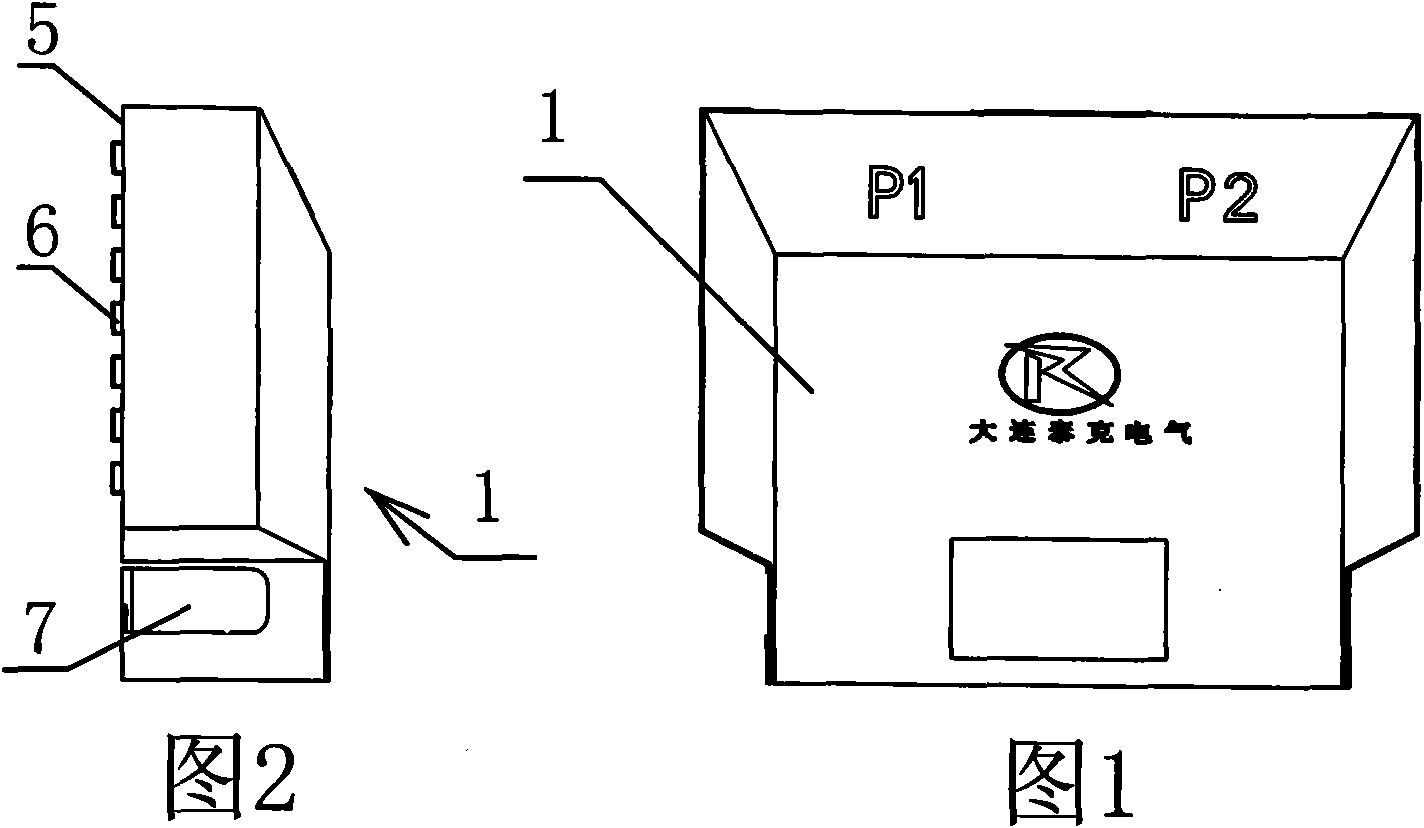

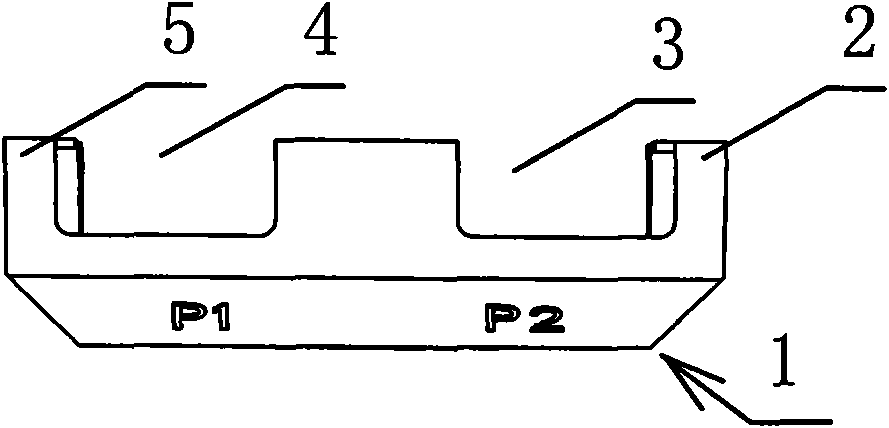

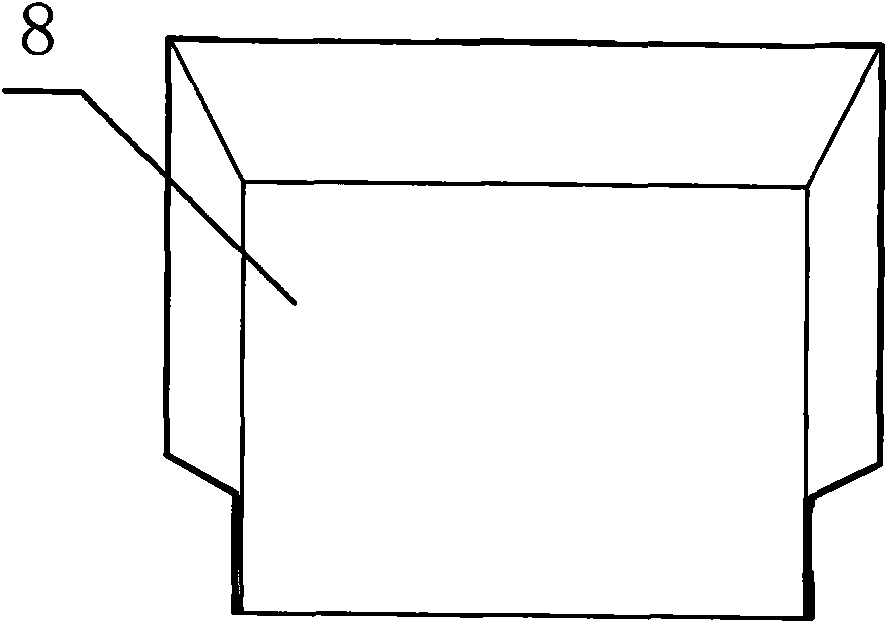

[0026] A special insulating protective shell for transformers, including a front protective shell and a rear protective shell, the wall thickness of which is 2 mm and made of polyurethane material; the front protective shell includes the front shell 1, the inlet and outlet gaps on the front bus 3, 4, front busbar lower inlet and outlet gaps 15, 16, front secondary line outlet and inlet gaps 7 and multiple stoppers 6 with the same structure; the front bus bar inlet and outlet gaps 3, 4 are respectively It is arranged on the left and right sides of the top of the front housing 1; the front secondary line outlet and inlet openings 7 with the same structure are respectively arranged on the left and right sides of the lower part of the front housing 1. The side standing edges 2, 5 are respectively provided with a plurality of left and right symmetrical stoppers 6, and the front busbar lower inlet and outlet notches 15, 16 are respectively provided on the left and right sides of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com