Sliding element, method of manufacturing the sliding element, and bearing device using the sliding element

A sliding material, sliding surface technology, used in sliding contact bearings, bearings in rotary motion, bearings, etc., to achieve the effect of simple manufacturing equipment, preventing thermal degradation, and offsetting shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

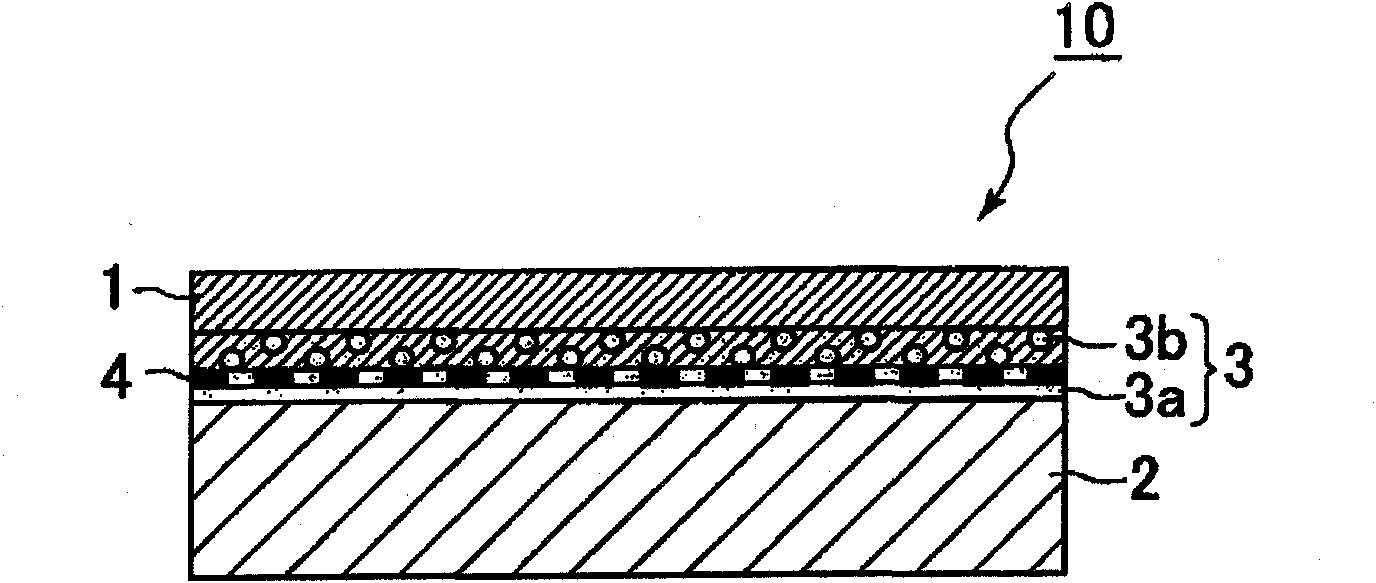

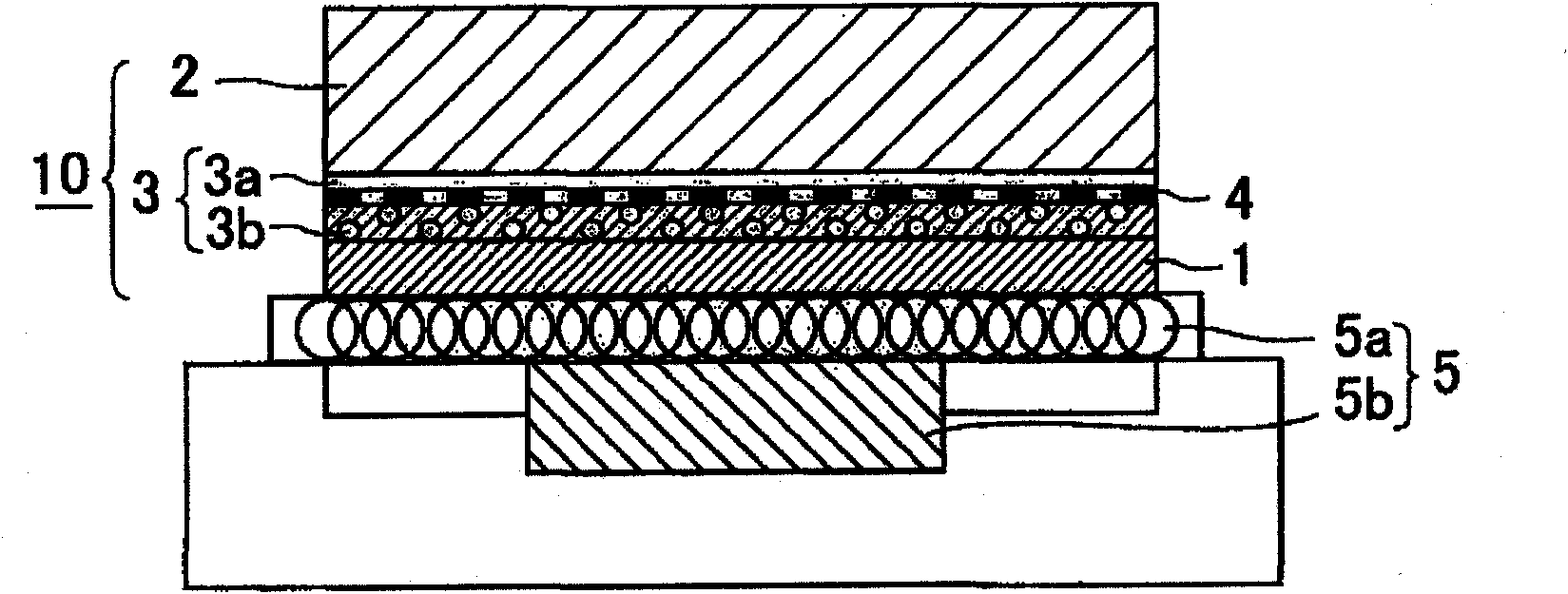

[0081] use as figure 2The arrangement shown produces a sliding material 10 according to the invention. Specifically, first, polytetrafluoroethylene (PTFE) resin material powder (average particle diameter of about 35 μm, melting point of about 327° C.) was introduced into a mold having a rectangular opening with a size of 300 mm×300 mm in an amount such that The thickness of the sliding surface member 1 is 13 mm, and the polytetrafluoroethylene resin material is the material of the sliding surface member 1 . Then, the same polytetrafluoroethylene (PTFE) resin material powder was mixed with Sn powder containing 0.7 wt % Cu (average particle diameter of about 50 μm, melting point of about 227° C.) used as a bonding material at a volume ratio of 1:1. The mixed powder mixture, which is the material of layer 3b, is introduced into the mold in such an amount that the resulting layer 3b has a thickness of 1 mm. Then, a 20-mesh pure iron flat-woven wire mesh used as a porous sheet m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com