Modular electromagnetic device with reversible generator-motor operation

A technology of electromagnetic devices and motors, which is applied to synchronous motors with stationary armatures and rotating magnets, electric components, electromechanical devices, etc., and can solve problems such as difficult design improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

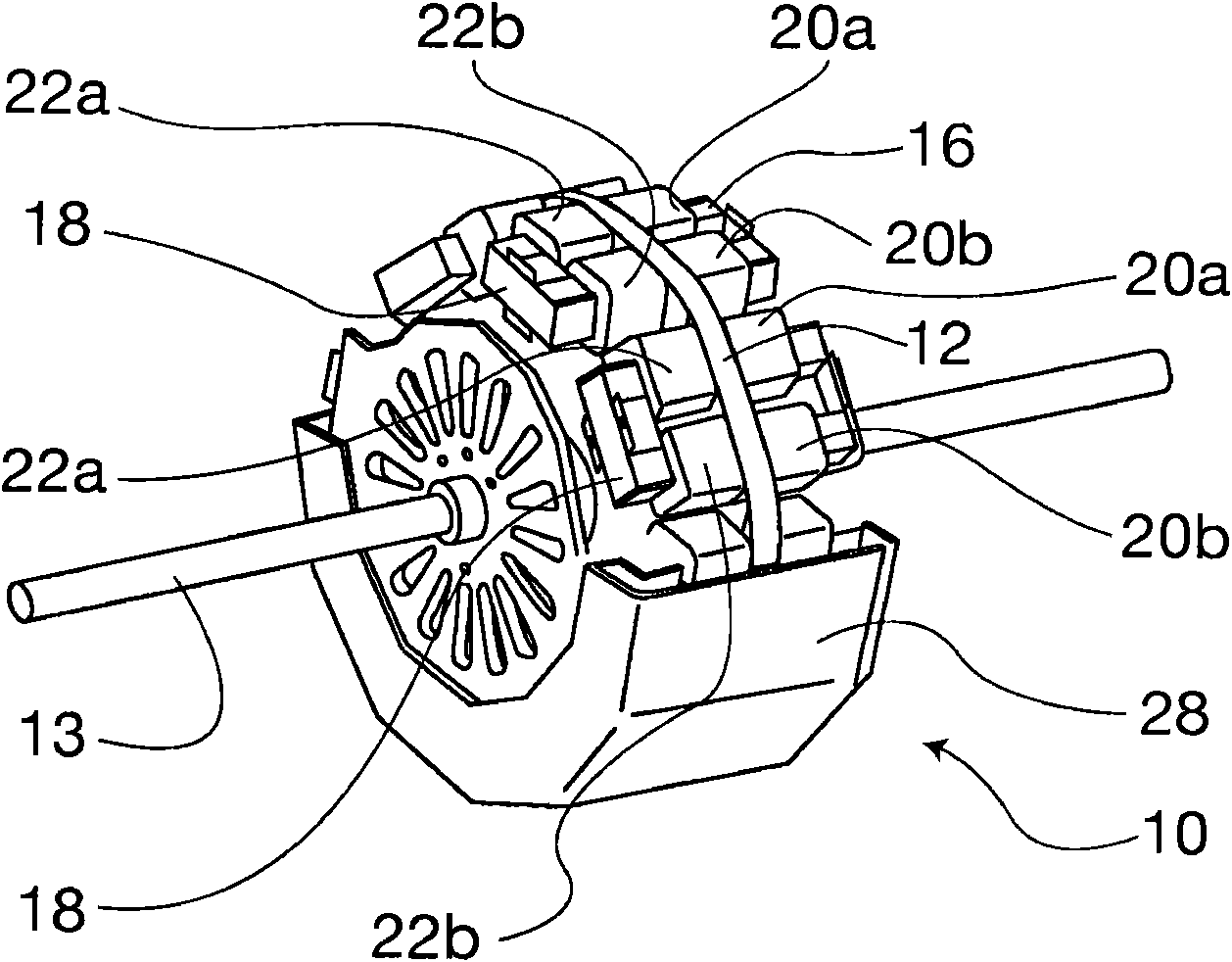

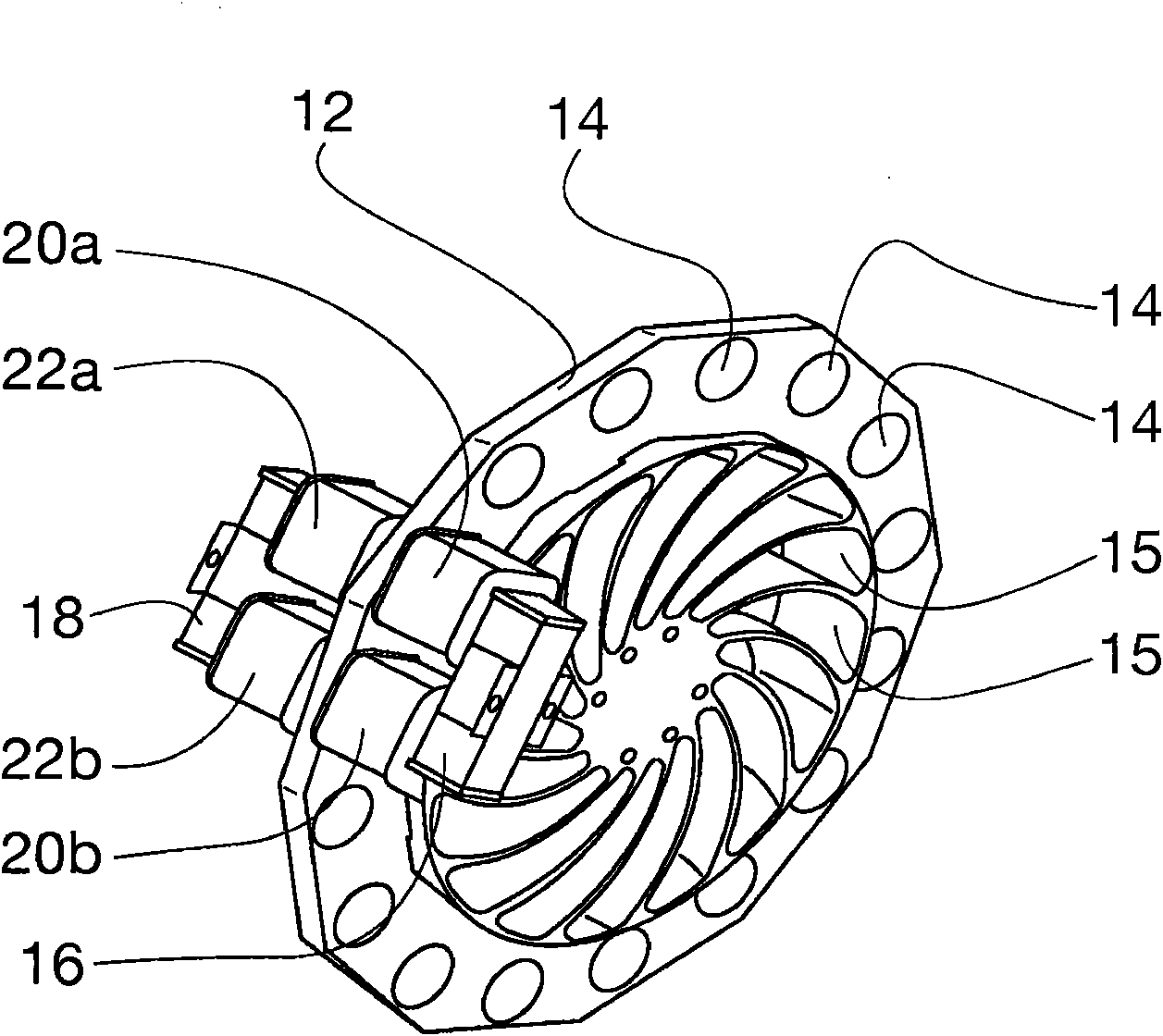

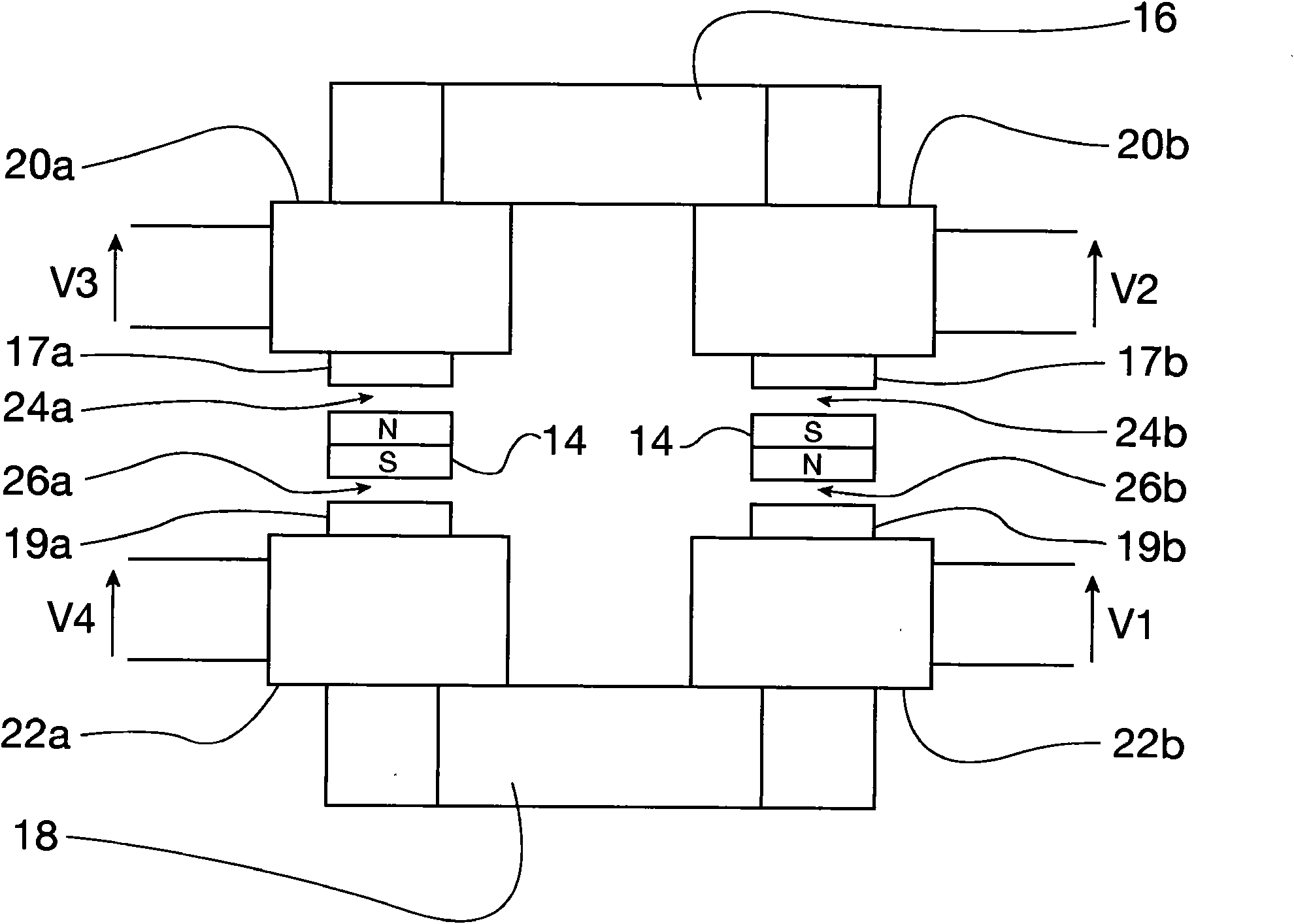

[0046] see Figure 1-3 , is the device of Embodiment 1 of the present invention, denoted by reference numeral 10, and is used to construct an axial motor.

[0047] The device 10 mainly includes two different structures.

[0048] The first structure is a disk or ring 12 (for simplicity, hereinafter referred to as disk), which forms the rotor of the device 10 , mounted on a shaft 13 . The main surface of the disk 12 contains a ring of identical permanent magnets 14 distributed in a regular manner along the circumference of the disk 12, at the outside near the edge of the disk. The magnets 14 are arranged on each surface of the magnetic disk 12 in such a manner as to form successive alternating and opposite magnetic poles. exist Figure 1-3 In the illustrated embodiment, the disk 12, in the areas not covered by the magnets 14, is made of a non-ferromagnetic material.

[0049] The central part of the magnetic disk 12 has a plurality of blades 15, which have a pushing action, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com