Modular driving device of elastic joints of multi-joint hopping robot

An elastic joint, modular technology, applied in the field of elastic joint modular drive device of small multi-joint jumping robot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

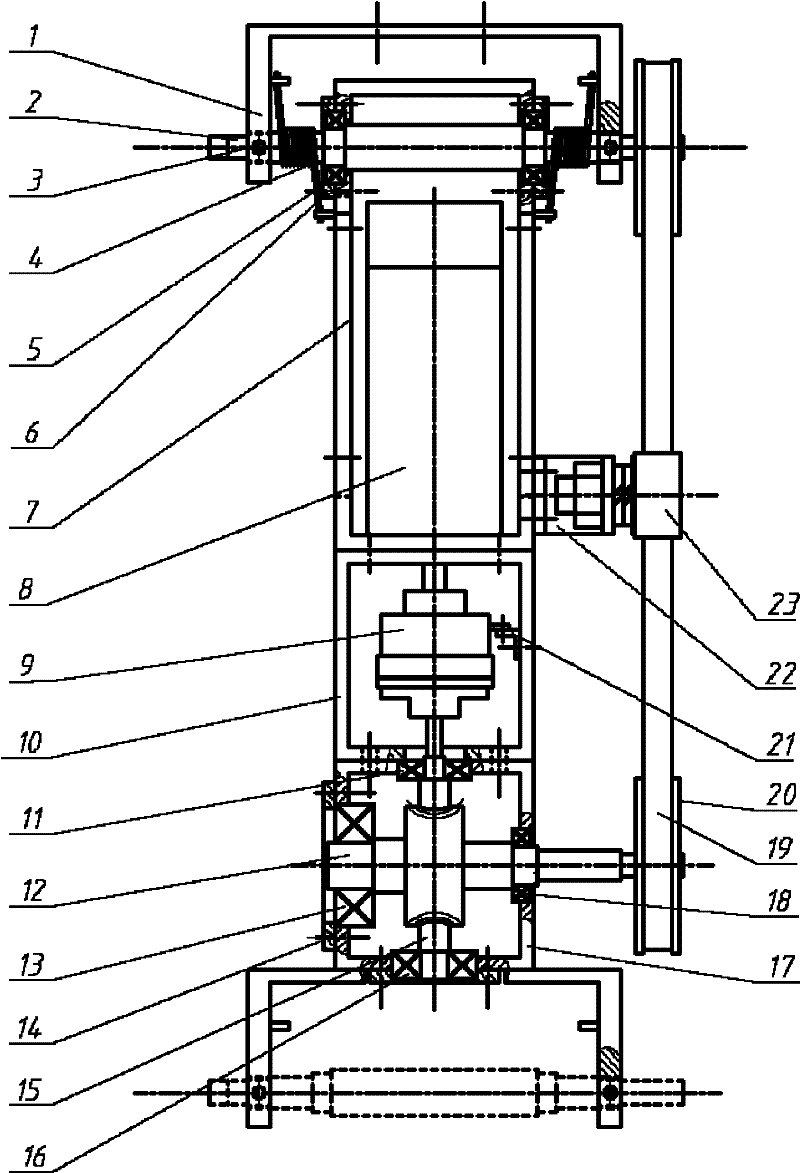

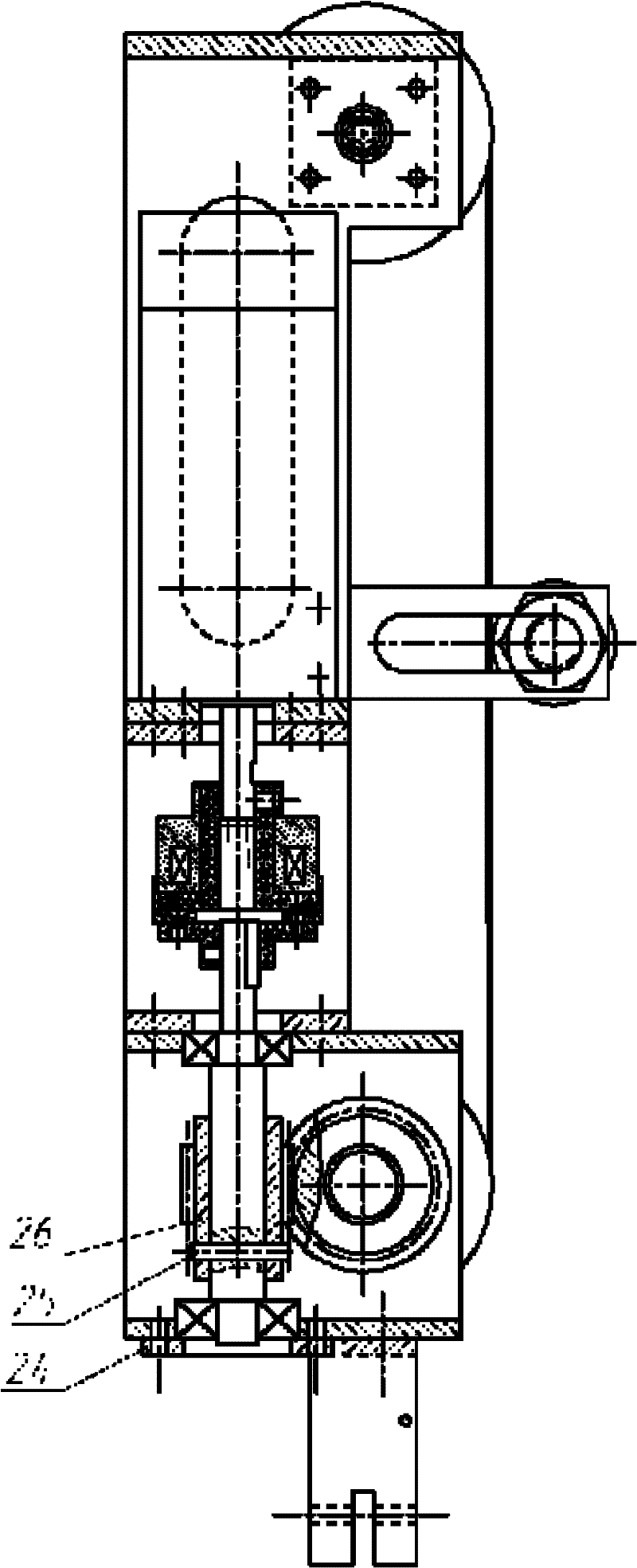

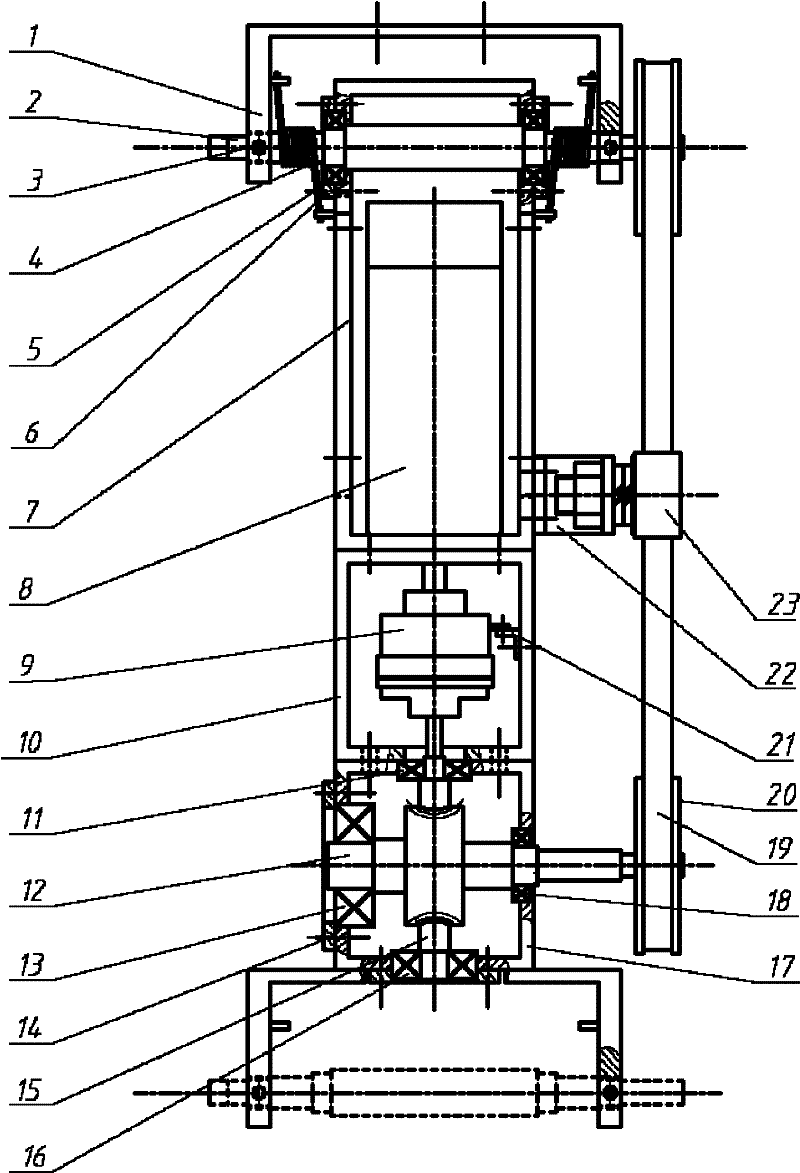

[0015] Below in conjunction with accompanying drawing, the present invention will be described in more detail:

[0016] combine figure 1 and figure 2 , The jumping robot elastic joint modular drive device is composed of a motor module, an electromagnetic clutch module, a worm gear module, an elastic joint shaft module, and a timing belt module. The motor module includes: a motor mounting frame 7 and a motor 8; the motor 8 is fixed on the motor mounting frame 7. Described electromagnetic clutch module comprises: electromagnetic clutch 9, electromagnetic clutch installation frame 10, electromagnetic clutch fixed frame 21; The worm gear module includes: worm gear mounting frame 17, worm 26, worm shaft 15, worm fixing pin 25, worm support small bearing 11, worm support large bearing 16, worm support large bearing end cover 24, worm gear shaft 12, The worm wheel supports the large bearing 13, the worm wheel supports the large bearing end cover 14, and the worm wheel supports th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com