Turning device for turning plate body and turning method

A technology of flipping device and plate body, applied in glass cutting device, glass manufacturing equipment, glass production and other directions, can solve problems such as relying on manual handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

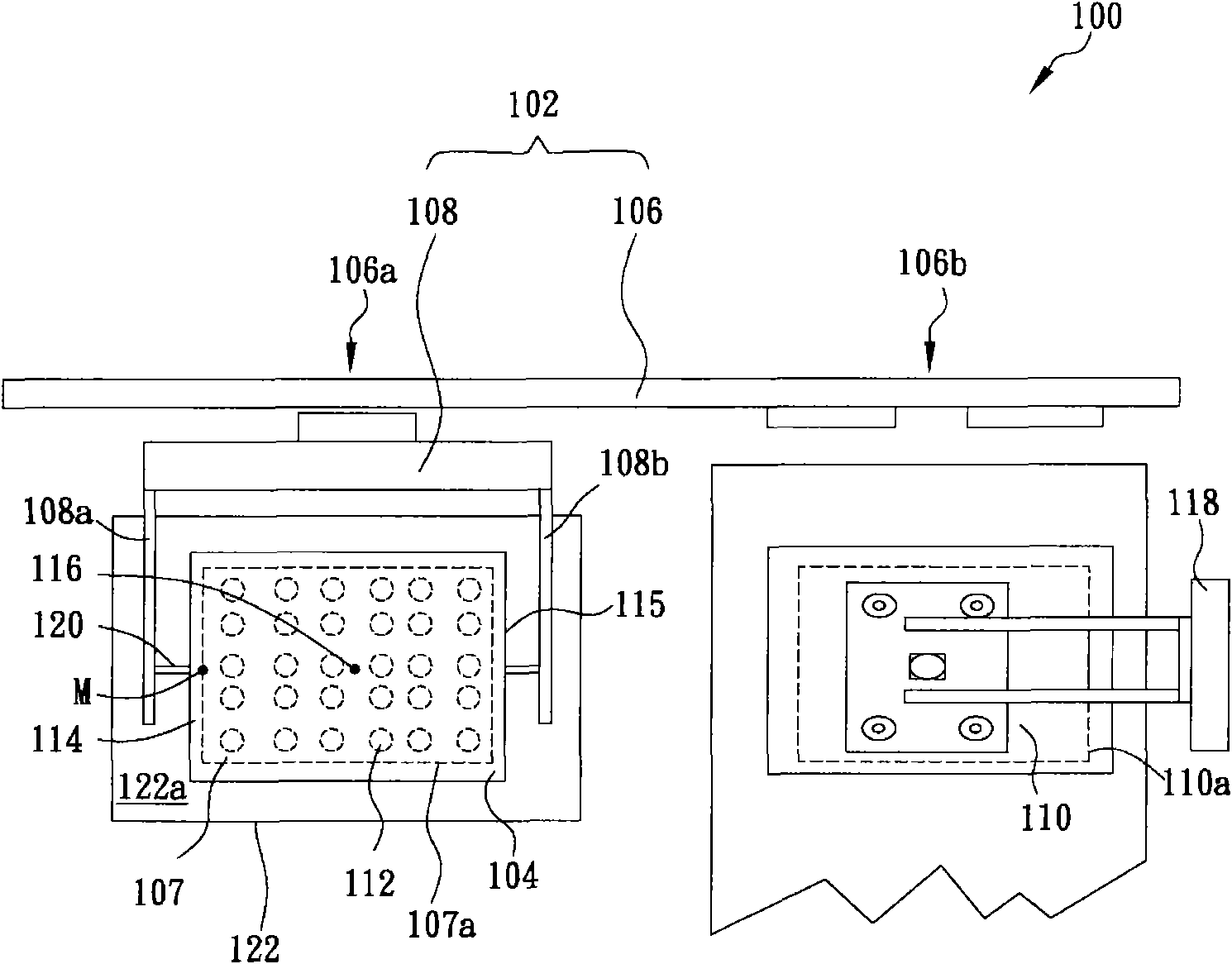

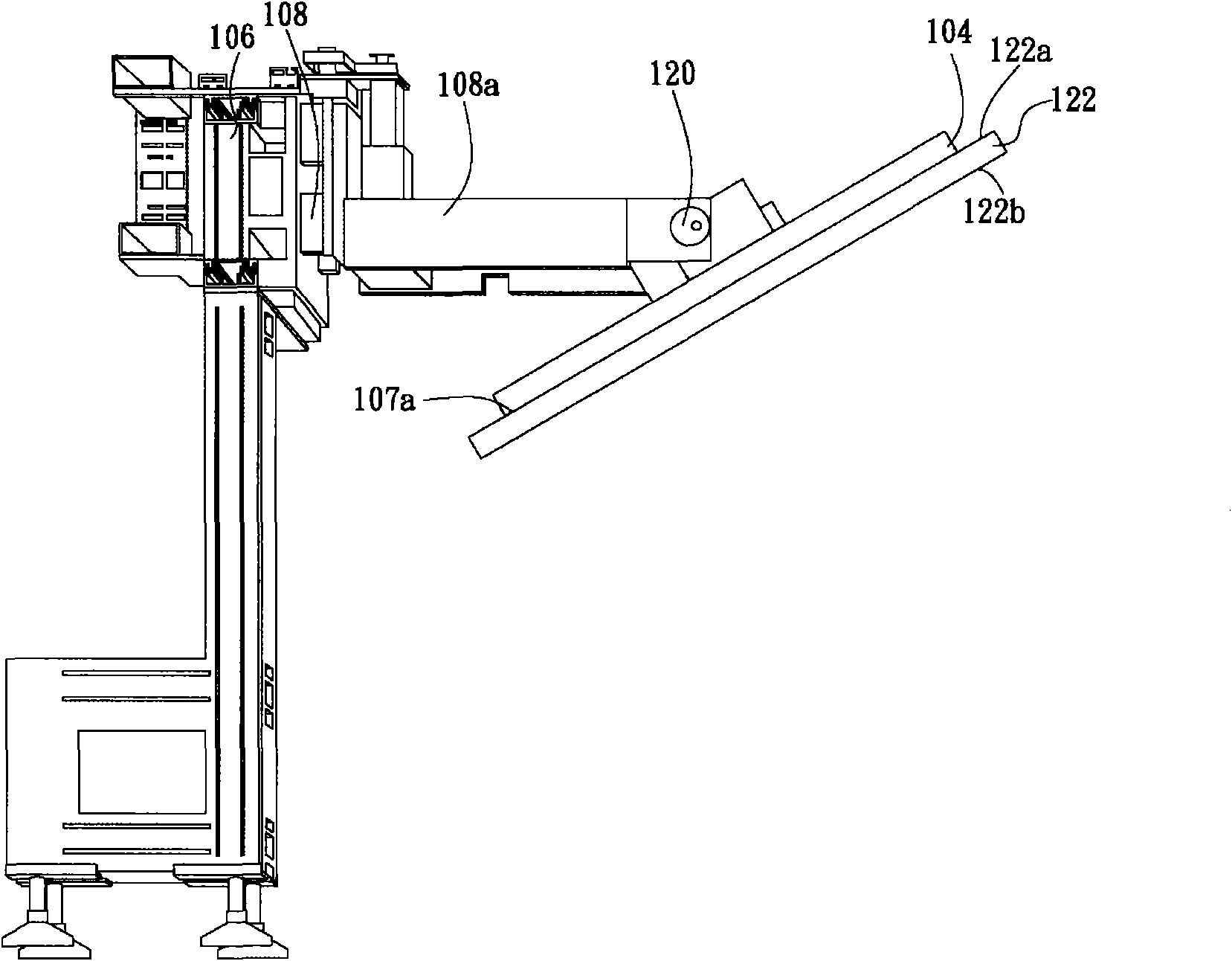

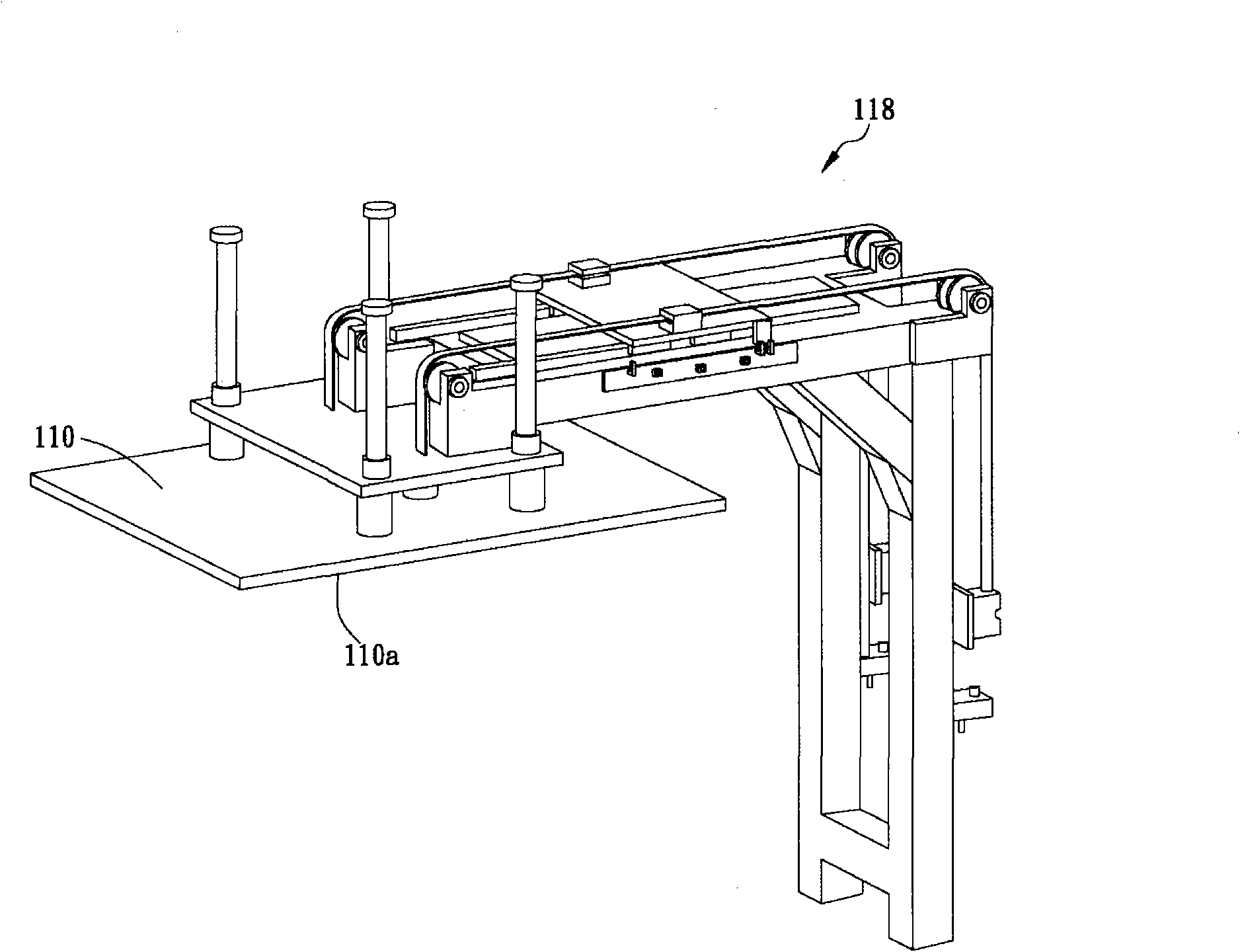

[0025] Please refer to figure 1 , figure 1 It is a schematic diagram showing a preferred embodiment of the turning device 100 of the present invention, and the process of turning over a plate body 122 . Such as figure 1 As shown, the turning device 100 includes a supporting structure 102 and a turning portion 104 . Wherein, the turning part 104 is pivotally connected with the supporting structure 102 and includes a suction device 107 . The adsorption device 107 is suitable for adsorbing and stabilizing the first surface 122 a of the plate body 122 according to control. After the adsorption device 107 and the first surface 122a of the plate body 122 are adsorbed and stabilized, the turning part 104 is adapted to drive the adsorption device 107 and the plate body 122 to turn over relative to the support structure 102 (preferably turn over 180 degrees substantially). In this way, the purpose of turning over the plate body 122 automatically is achieved.

[0026] In detail, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com