Cutoff device for composite fibrofelt

A technology of composite fiber mat and cutting device, which is applied in the direction of textiles, papermaking, and textile material cutting, etc. It can solve the problems of energy consumption, empty running, and long time consumption, so as to improve production efficiency, reduce labor intensity, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

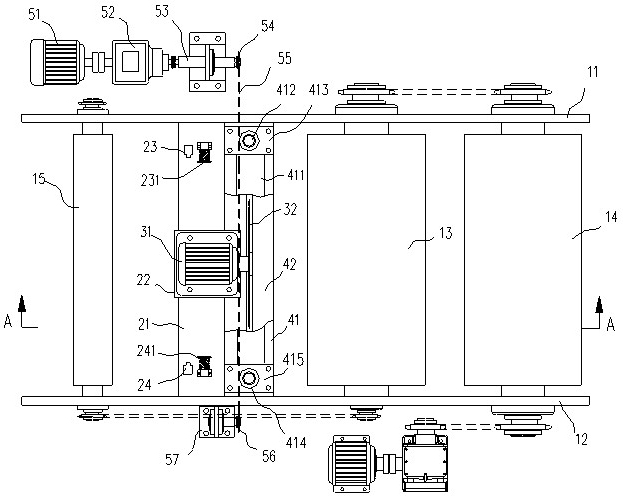

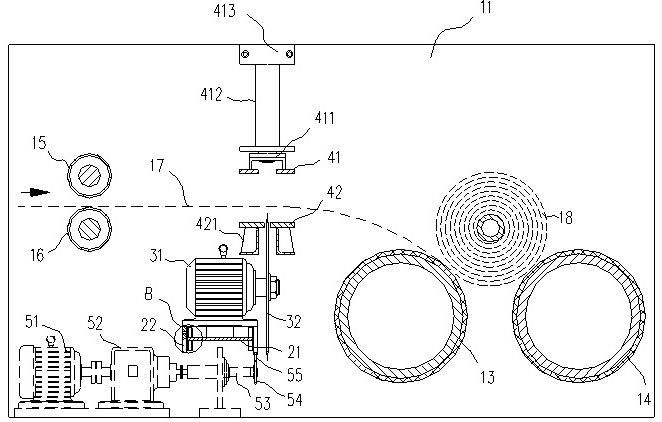

[0015] Such as figure 1 , figure 2 As shown, the present invention is arranged between the guide rollers 15, 16 and the revolving rollers 13, 14 of the winding device, and it includes a cutting mechanism, a walking mechanism and a pressing felt mechanism.

[0016] The cutting mechanism includes a disc blade 32 and a driving motor 31 thereof.

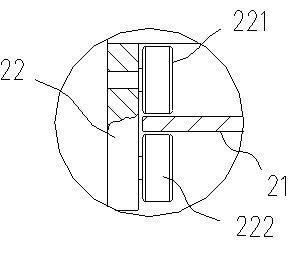

[0017] The traveling mechanism includes a guide rail 21, a sliding bracket 22 and a driving device that drives the sliding bracket 22 to reciprocate along the guide rail 21. The guide rail 21 is fixed on the frame 11, 12 of the winding device along the width direction of the composite fiber felt 17; the sliding bracket 22 The two sides below are respectively provided with guide bearings 221, 222 that cooperate with the upper and lower surfaces of the guide rail 21, such as image 3 As shown, the sliding bracket 22 can reciprocate along the guide rail 21, and the sliding bracket buffer positioning device composed of the limit devices 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com