Remote-controlled pulley-type shielding bracket under coal mine

A technology for shielding brackets and pulleys, which is applied in mine roof brackets, mining equipment, earthwork drilling and mining, etc. It can solve problems such as high labor intensity, inability to adapt to the rapid relocation of high-yield and high-efficiency fully mechanized mining face, waste of timber support height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

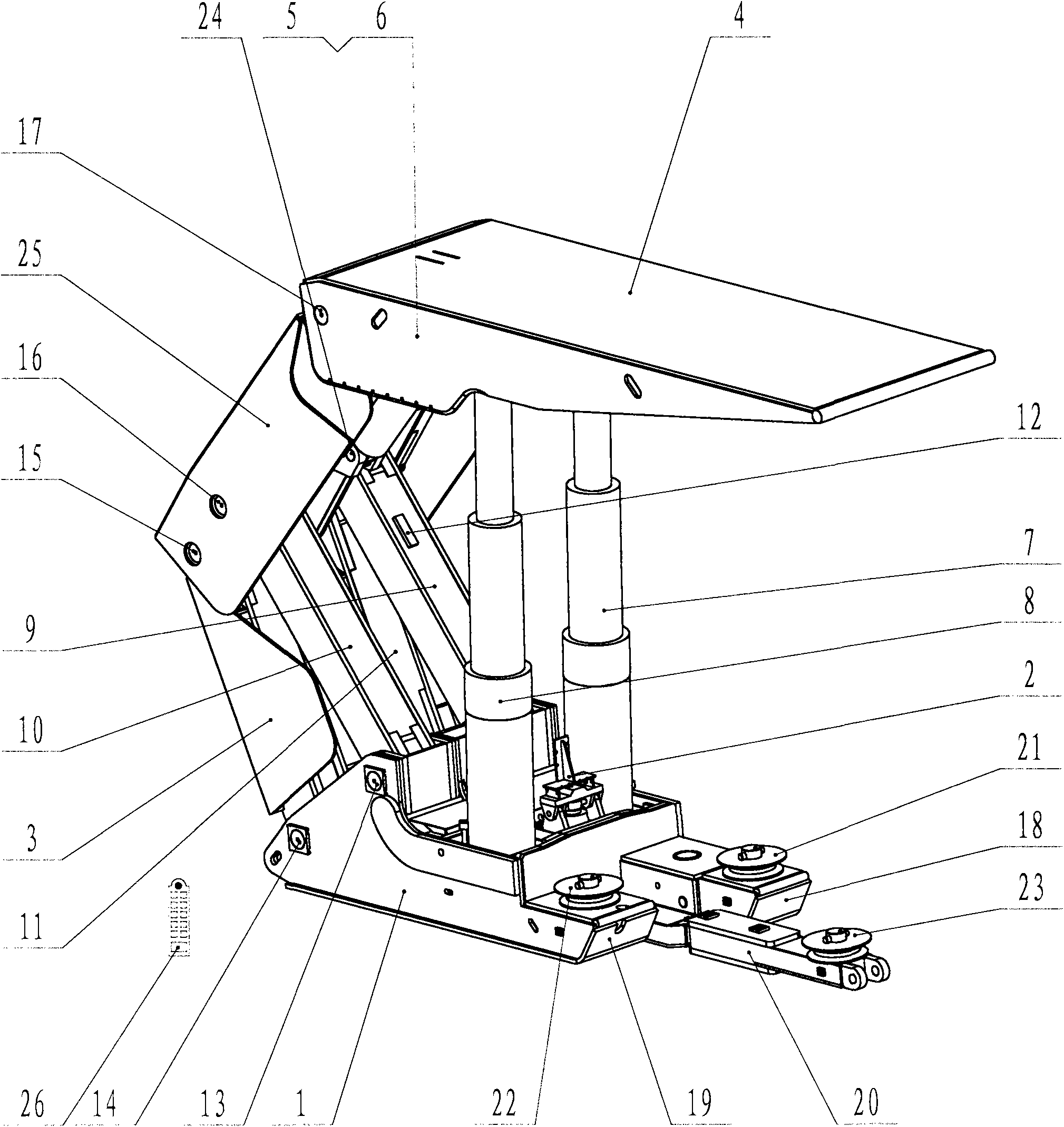

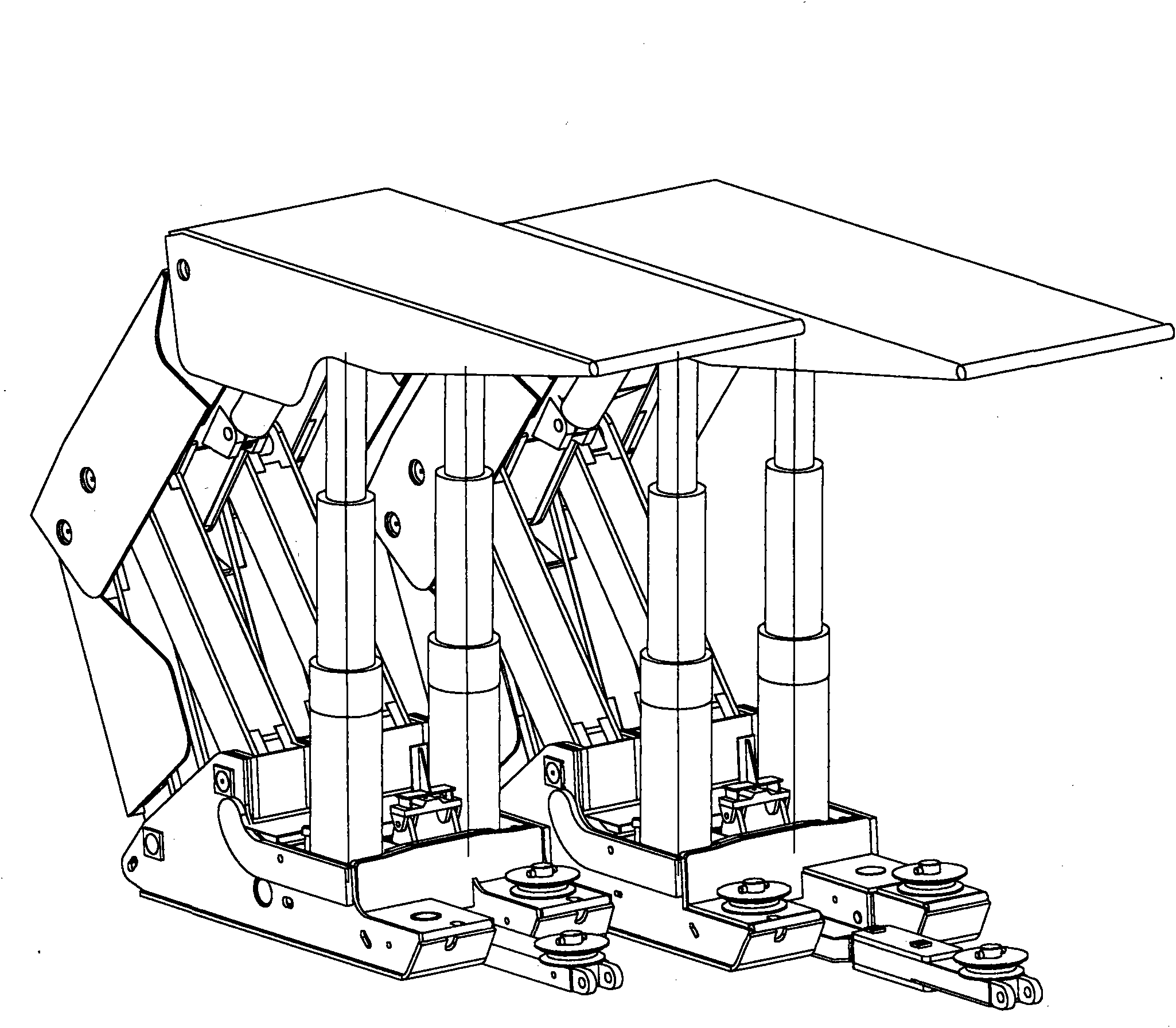

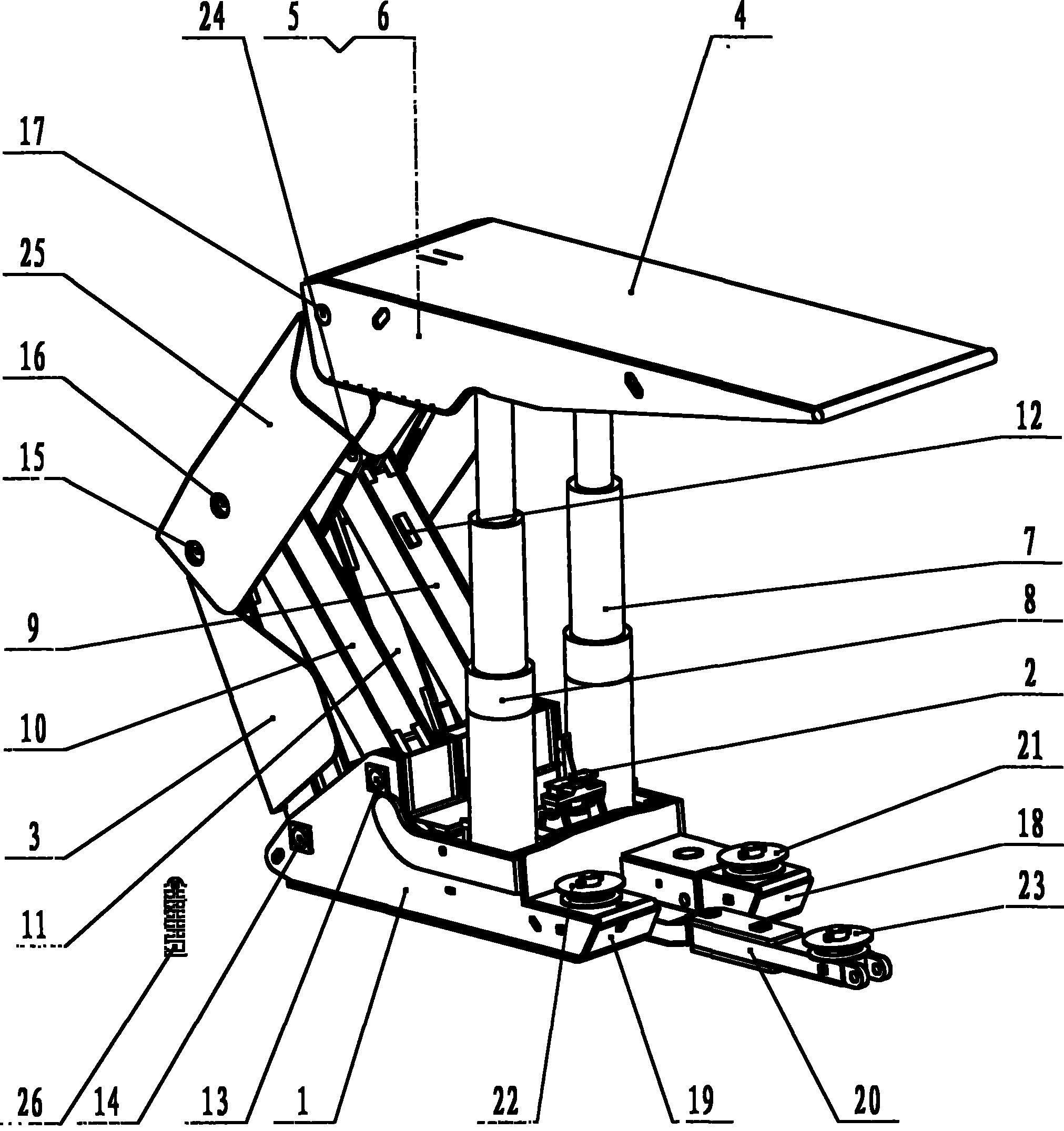

[0024] figure 1 Shown is the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0025] A hydraulic control mechanism 2 is arranged at the upper middle position of the base 1, and first and second column oil cylinders 7 and 8 are vertically arranged on both sides of the hydraulic control mechanism 2;

[0026] The front part of the base 1 is symmetrically provided with first and second drawing seats 18, 19, and a third drawing seat 20 is arranged in the middle; the first, second and third drawing seats 18, 19, 20 are There are first, second and third pulling pulleys 21, 22 and 23;

[0027] The first and second front connecting rods 9 and 10 are arranged at the rear of the base 1, and are connected by the first lever shaft 13; 25 is connected, and the cover beam 25 is connected with the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com