Periscopic image measurement instrument

An image measuring instrument and periscope technology, applied in the field of image measuring instruments, can solve the problems of large limitations, inability to measure the inner wall of holes, and limit the application scope of the image measuring instrument, and achieve the effect of broadening the application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

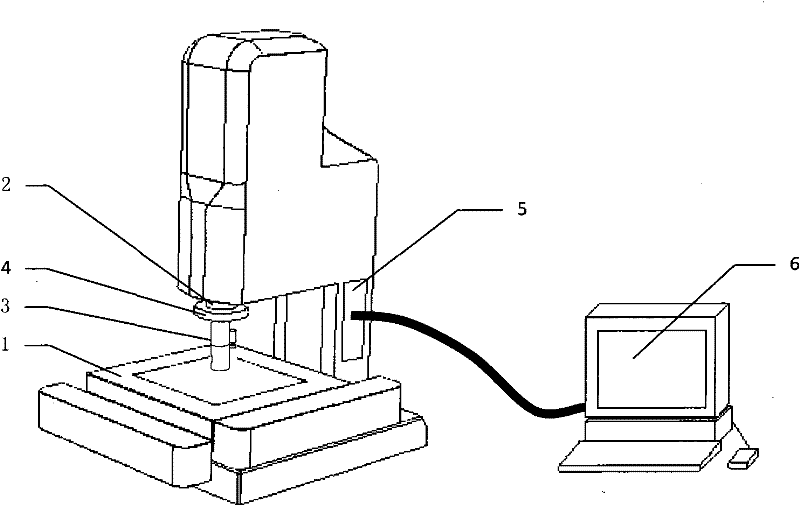

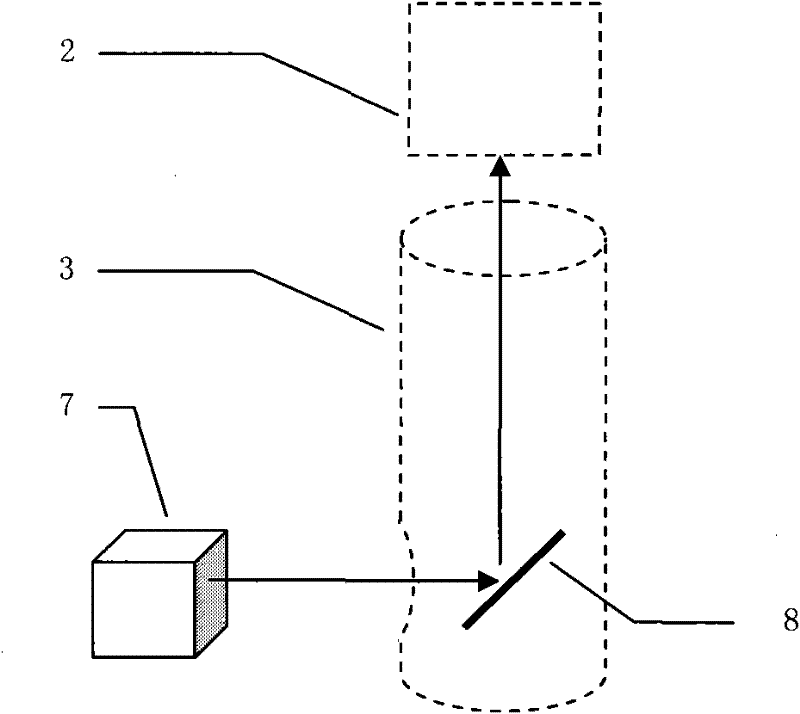

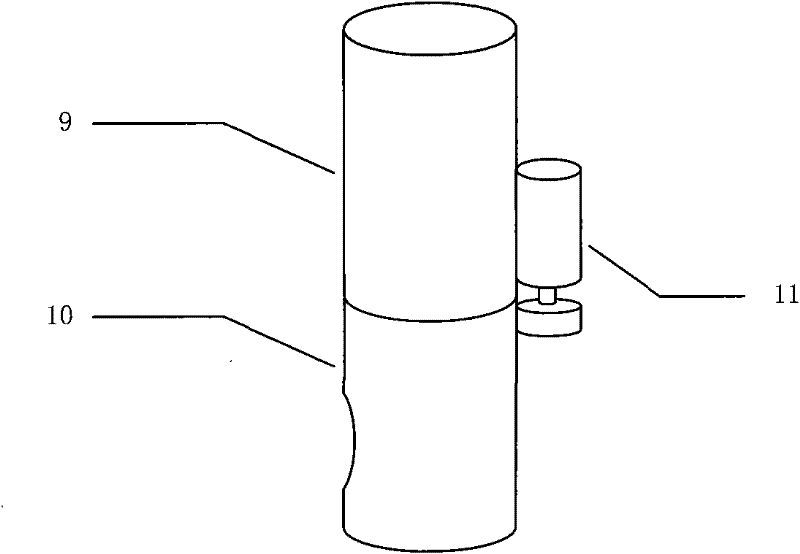

[0018] The periscope image measuring instrument is based on a three-axis CNC mobile table [1], equipped with a microscope [2], a periscope objective lens [3], a CCD, a lighting system [4], an electrical control card [5] and a personal computer [ 6].

[0019] The three-axis CNC automatic mobile workbench [1] is divided into XY mobile platform and Z axis, the XY mobile platform is used to carry the workpiece to be measured, the microscope [2] is fixed on the Z axis, and the periscope objective lens [3] is fixed at the lower end of the microscope. The up and down movement of the Z axis can control the focus sharpness of the microscope. The three axes of XYZ are composed of linear guide rail, ball screw and DC servo control system, which can obtain very high positioning accuracy. The three-axis workbench can be controlled by the computer and driven by the electrical control card [5] to realize program control and meet the needs of automatic measurement.

[0020] The personal com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com