Heat source temperature measurement device and method for electrical heating

A temperature measuring device and electric heating technology, applied in the direction of measuring devices, thermometers using electrical devices, and electrical/magnetic components directly sensitive to heat, etc., can solve the problems of inaccurate measurement sides and inconsistent measurement accuracy, and eliminate Delay error, the effect of eliminating sampling error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

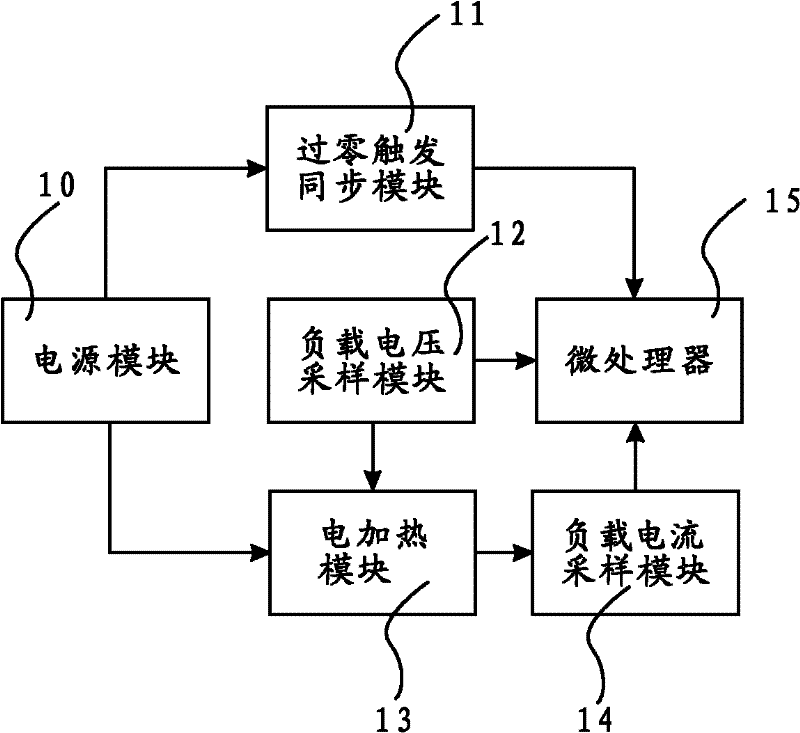

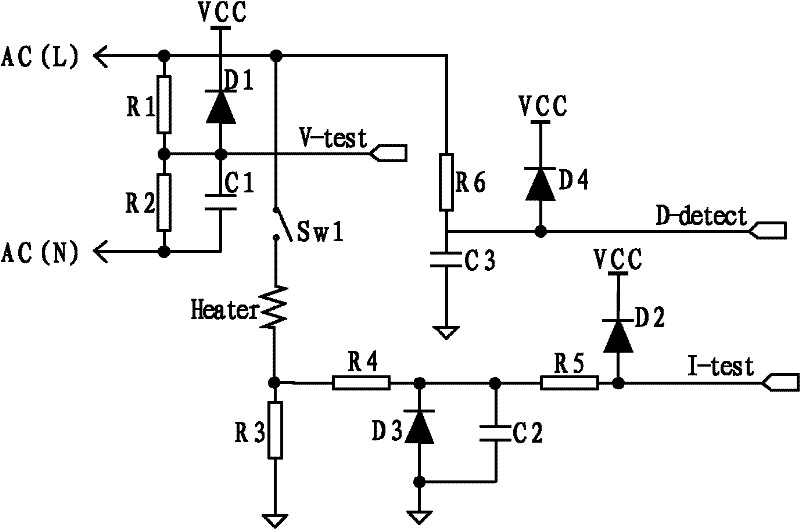

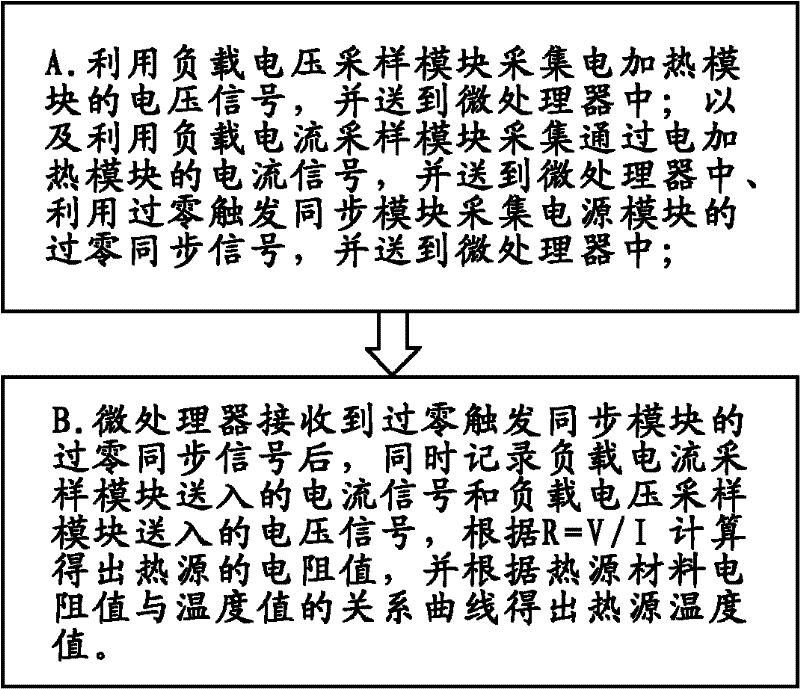

[0023] see figure 1 The heat source temperature measuring device for electric heating of the present invention includes a load voltage sampling module 12, a load current sampling module 14, a zero-crossing trigger synchronization module 11 and a microprocessor 15, and the microprocessor 15 has at least a first input terminal, a second Two input terminals and a third input terminal; the input terminal of the load voltage sampling module 12 for collecting the voltage at both ends of the electric heating module 13 is connected to the electric heating module 13, and the output terminal of the load voltage sampling module 12 is connected to the microprocessor 15 The first input end is connected; the input end of the load current sampling module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com