A method for operating an electrolyzer safely and economically

An electrolyser, safe technology, applied in the field of electrolyser, can solve the problem of misleading voltage measurement results, inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

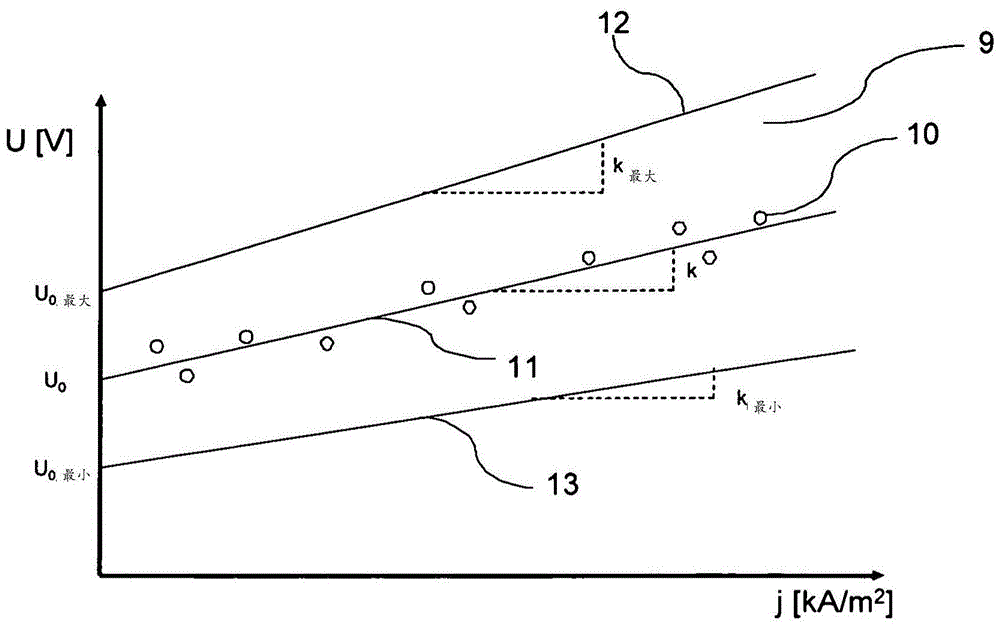

[0111] In graphical representation 9, Figure 1a shows that depending on the current density j(kA / m 2 ) voltages 10 which have been measured in a cell element of the electrolyzer. The resulting voltage regression line has reference number 11 and on the ordinate axis the voltage value U 0 . Furthermore, the voltage regression line 11 has a slope k. From the graphical representation 9 it is seen that with slope k 最小 and k 最大 and the voltage value U on the ordinate axis 0,最大 and U 0,最小 The voltage straight line 12,13. Slope k, k 最大 and k 最小 and the voltage value U 0 , U 0,最大 and U 0,最小 Represents battery cell properties such as electrode coatings, or the ohmic resistance of separators, electrolytes, and metal compartments.

[0112] The voltage straight lines 12 and 13 based on empirical values indicate the boundary conditions of the safe voltage working range, that is, as long as the voltage regression line 11 extends between the voltage straight lines 12 and 13, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com